Method and device for pretreatment of cemented carbide tool before depositing diamond coating

A technology of diamond coating and cemented carbide, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem that it cannot be applied to large-scale industrial production, the preparation method of composite transition layer is complex, and the hindering effect is not obvious and other problems to achieve the effect of eliminating cleaning treatment, speeding up boronizing speed and improving gas activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

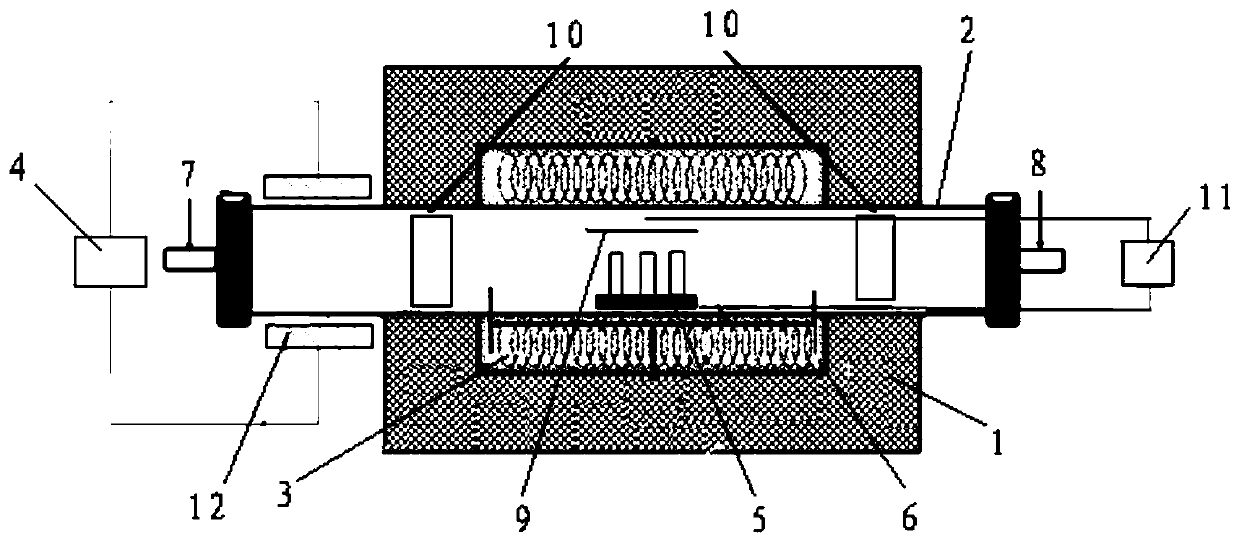

[0044] Participate in figure 1 , a cemented carbide tool pretreatment device before depositing a diamond coating, comprising a furnace body 1, a furnace chamber 2, an electric heating body 3, a plasma generating power supply 4, and a sample stage 5, and the furnace body 1 is provided with a furnace chamber 6, and the The furnace 2 is a tubular cavity, which is arranged coaxially with the furnace chamber 6 and installed in the furnace body 1. An electric heating body is arranged in the furnace chamber 6 and is located around the outer wall of the furnace chamber 2; One end of the furnace 2 is provided with an air inlet 7, the other end is provided with an air outlet 8, and the middle part of the furnace 2 is provided with a sample stage 5; the sample stage 5 is provided with a bias electrode 9, and the bias electrode 9 It is electrically connected to the bias power supply 11; on both sides of the sample table 5, there is a block 10 in the furnace; on the outer wall of the furna...

Embodiment 2

[0046] (1) First chemical microetching: Put the cemented carbide milling cutter into 50% concentration of sodium hydroxide solution and ultrasonically clean it for 10 minutes with an ultrasonic power of 50W, and then put it into 20% concentration of acid oxygen water for ultrasonic cleaning 20s, after etching, wash and set aside.

[0047] (2) Plasma activation treatment: Put the cemented carbide cutter into the attached equipment, vacuumize, heat up to 600°C after vacuuming, then feed in hydrogen gas with a flow rate of 50 sccm, and turn on the power supply of the radio frequency plasma device and For the power supply of the RF bias device, adjust the plasma power to 300W, the bias voltage to 20V, and process for 90 minutes.

[0048] (3) Plasma-enhanced gaseous boride treatment: close the bias device; the temperature of the furnace is raised to 800° C., and the flow rate is 20 sccm of diborane. At this time, the furnace is a mixed gas composed of diborane and hydrogen, and the...

Embodiment 3

[0056] (1) First chemical microetching: Put the cemented carbide plane substrate into 50% concentrated sodium hydroxide solution and ultrasonically clean it for 15 minutes with an ultrasonic power of 50W, and then put it into 20% concentration of acid oxygen water for ultrasonic cleaning 30s, after etching, wash and set aside.

[0057] (2) Plasma activation treatment: put the cemented carbide cutter into the attached equipment, vacuumize, heat up to 700°C after vacuuming, then feed in hydrogen gas with a flow rate of 50 sccm, and turn on the power supply of the radio frequency plasma device and For the power supply of the RF bias device, adjust the plasma power to 200W, the bias voltage to 30V, and process for 90 minutes.

[0058] (3) Plasma-enhanced gaseous boride treatment: close the bias device, raise the furnace temperature to 900°C, and feed diborane with a flow rate of 30 sccm. At this time, the furnace is a mixed gas composed of diborane and hydrogen, and at the same ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com