Cigarette formula quality trend analysis method based on volatile characteristic components in cut tobacco

A trend analysis and volatile technology, applied in the direction of tobacco, tobacco processing, application, etc., to reduce the cost of detection, avoid subjectivity, and ensure the accuracy and sensitivity of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

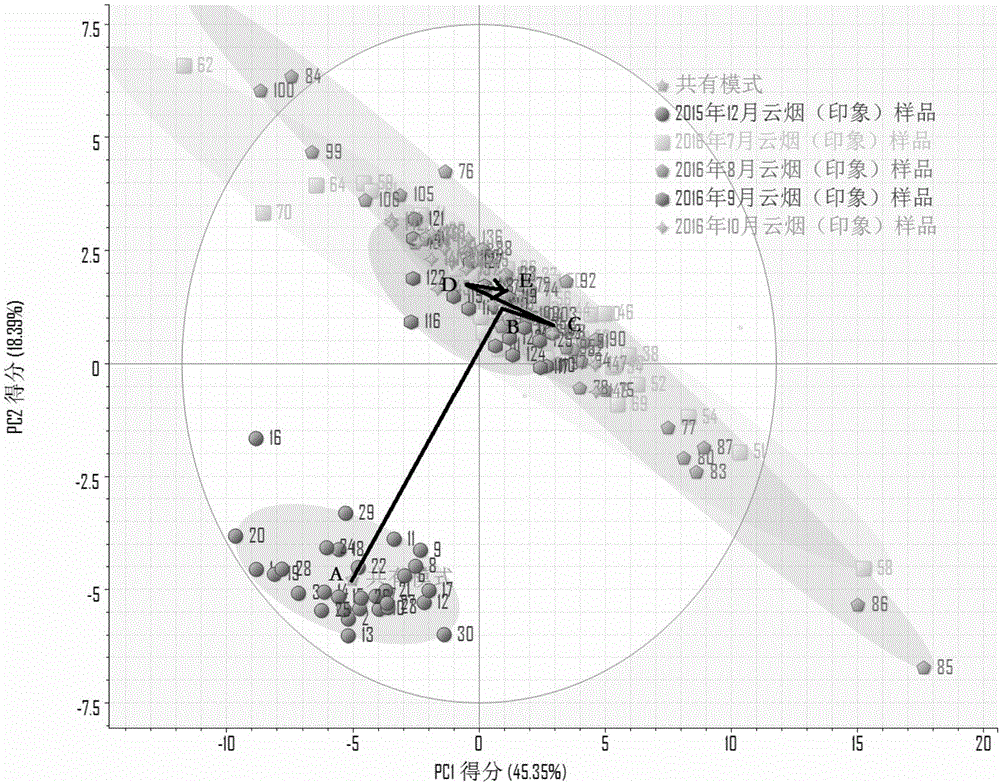

[0036] Trend analysis of formula quality for Yunyan (impression) brand

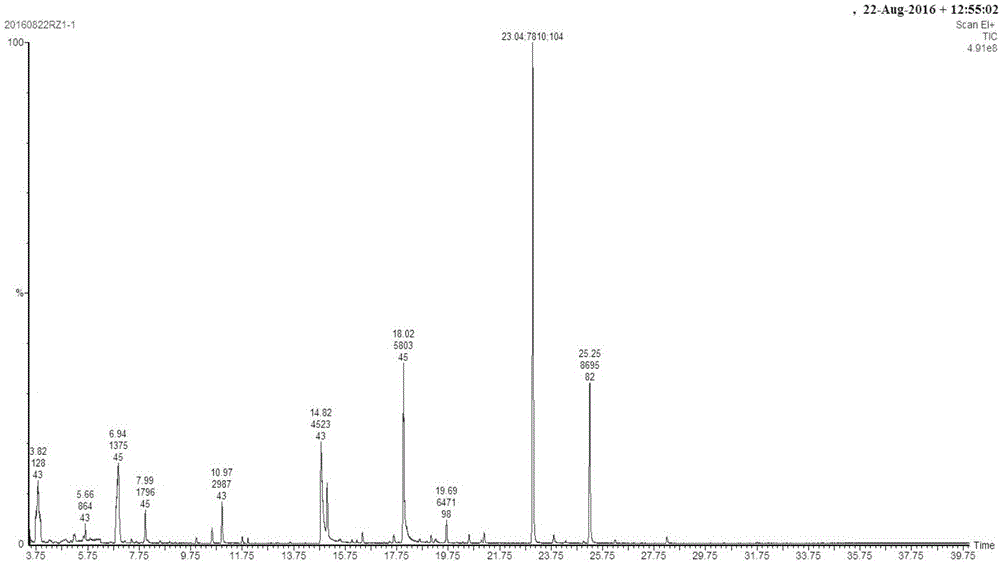

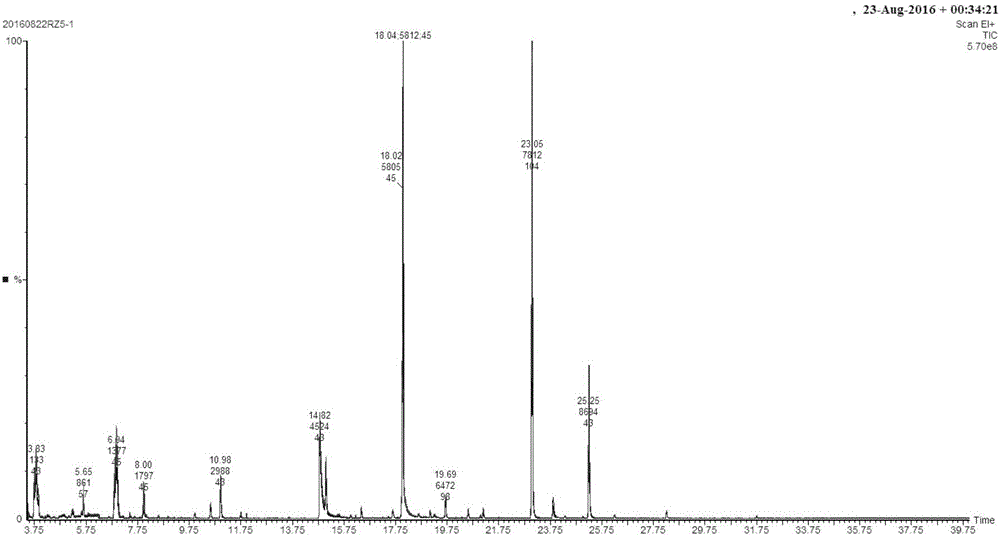

[0037] 1. Instruments, reagents and instrument working conditions

[0038]1) Instruments: Headspace Gas Chromatography Mass Spectrometer (G1888+7890A+5975C, Agilent Company, USA); DB-WAX Chromatographic Column (30m×0.25mm id×0.25μm df, Agilent Company, USA); Analytical Balance (Sensitive 0.1mg, Swiss MettlerToledo company); vibrating shaker (3017 German GFL company); 0.45μm organic phase filter membrane; 5mL pipette gun; other commonly used equipment in the laboratory.

[0039] 2) Reagents: Unless otherwise specified, use reagents of analytical grade or above. Water should meet the requirements of the first-class water in GB / T6682. 20 standard samples of volatile organic compounds, including 2-pentan-one, 6-methyl-3,5-heptadien-2-one, 3-methyl-3-buten-2-one, 2-pentan Alkenal, γ-nonanolide, bread ketone, 3-hydroxy-2-butanone, 2-ethyl-1-hexanol, 2-acetylfuran, benzaldehyde, 2-heptanol, 5-methylfurfural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com