Application of glacial acetic acid in freeze-drying process of Panax Notoginseng saponins or composition thereof

A technology of Panax notoginseng saponins and freeze-drying method, which is applied in the field of chemical drugs, can solve the problems of no freezing method and conditions, long turnaround time, and large production energy consumption, and achieve significant economic and social benefits. Freeze-drying The effect of short cycle time and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

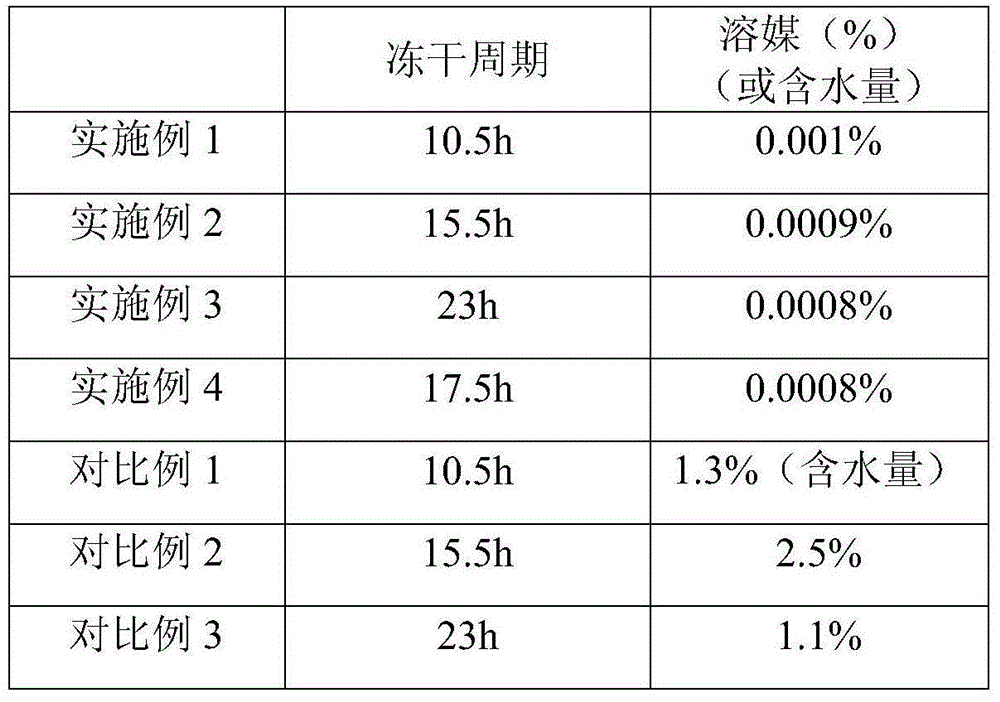

Examples

Embodiment 1

[0031] Weigh Panax notoginseng total saponins, operate according to the following steps:

[0032] 1) Pre-freezing: add Panax notoginseng saponins into glacial acetic acid with a water content of 5%, dissolve at 20°C to make a 0.5% solution, filter, and pack the filtrate into open containers, and place in a freeze-drying cabinet. Continue to cool down to 5°C within 0.25h, and maintain this temperature for 0.5h;

[0033] 2) Freezing and system balance: After the pre-freezing is completed, continue to cool down within 0.25 hours, lower the temperature in the freeze-drying cabinet to -5°C, and maintain this temperature for 0.5 hours, and then maintain the same temperature to freeze The pressure in the dry cabinet is adjusted to 2Pa and maintained for 1.5h;

[0034] 3) Sublimation: maintain the vacuum at 2Pa, increase the temperature of the inner plate layer of the freeze-drying cabinet from the base temperature of -5°C to 5°C, and keep it at this temperature for 1.5 hours; then k...

Embodiment 2

[0039] Weigh Panax notoginseng total saponins, operate according to the following steps:

[0040] 1) Pre-freezing: Add Panax notoginseng saponins to glacial acetic acid with a water content of 2%, dissolve at 30°C to make a 5% solution, filter, pack the filtrate into open containers, and place in a freeze-drying cabinet. Continue to cool down to 0°C within 0.5h, and maintain this temperature for 0.75h;

[0041] 2) Freezing and system balance: After the pre-freezing is completed, continue to cool down within 0.5 hours, lower the temperature in the freeze-drying cabinet to -15°C, and maintain this temperature for 0.75 hours, and then maintain the same temperature to freeze The pressure in the dry cabinet is adjusted to 10Pa and maintained for 2h;

[0042]3) Sublimation: maintain the vacuum degree at 10Pa, raise the temperature of the inner plate layer of the freeze-drying cabinet from the base temperature of -15°C to 0°C, and keep it at this temperature for 2 hours; then keep t...

Embodiment 3

[0047] Weigh Panax notoginseng total saponins, operate according to the following steps:

[0048] 1) Pre-freezing: Add Panax notoginseng saponins to anhydrous glacial acetic acid, dissolve at 40°C to make a 20% solution, filter, divide the filtrate into open containers, put it in a freeze-drying cabinet, and keep it for 1 hour Cool down to -5°C, and maintain this temperature for 1h;

[0049] 2) Freezing and system balance: After the pre-freezing is completed, continue to cool down within 1 hour, lower the temperature in the freeze-drying cabinet to -30°C, and maintain it at this temperature for 1 hour, and then keep the temperature constant to cool the freeze-drying cabinet The pressure inside is adjusted to 50Pa and maintained for 3h;

[0050] 3) Sublimation: maintain the vacuum at 50Pa, increase the temperature of the inner plate layer of the freeze-drying cabinet from the base temperature of -30°C to -5°C, and keep it at this temperature for 3 hours; then keep the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com