A kind of freeze-drying method of erythromycin lactobionate

An erythromycin lactobionate and freeze-drying technology, which is applied in the directions of freeze-drying transportation, drying, and pharmaceutical formulations, can solve the problem of shortening the freeze-drying cycle, unable to take into account the quality of erythromycin lactobionate and freeze-drying process time, increase, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Turn on the freeze dryer to cool down the temperature of the freeze drying box to 3°C, push the glass bottle containing the liquid medicine into the vacuum freeze dryer, and lower the temperature of the product to -35°C at a cooling rate of 8°C / h, which takes 285 minutes , and then turn on the vacuum pump;

[0048] Turn on the electric heating, turn off the refrigeration unit, raise the temperature of the product to about 0°C at a heating rate of 13°C / h, which takes 161.5 minutes, and then raise the temperature of the product to 50°C at a heating rate of 4°C / h, which takes 750 minutes;

[0049] Insulate at a temperature of 50°C for 300 minutes, then turn off the vacuum pump and turn off the electric heating;

[0050] Press the plug and take it out of the box to obtain the finished product of erythromycin lactobionate.

[0051] The present embodiment process takes 1496.5min.

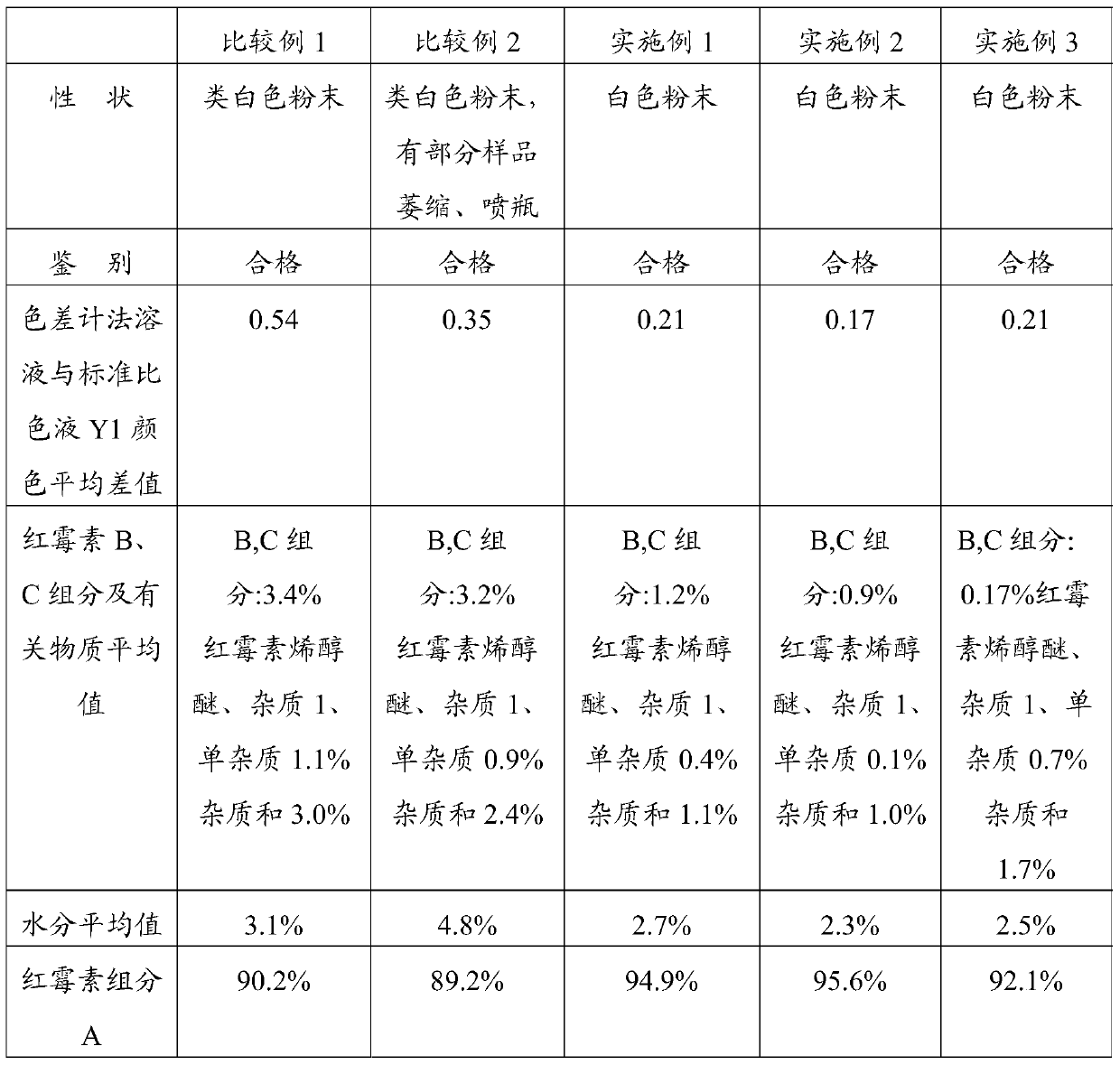

[0052] The quality of the erythromycin lactobionate finished product that the present inventi...

Embodiment 2

[0060] Turn on the freeze dryer to cool down the temperature of the freeze-drying box to 5°C, push the glass bottle containing the liquid medicine into the vacuum freeze-dryer, and lower the temperature of the product to -38°C at a cooling rate of 10°C / h, which takes 258 minutes , and then turn on the vacuum pump;

[0061] Turn on the electric heating, turn off the refrigeration unit, raise the temperature of the product to about 0°C at a heating rate of 18°C / h, it takes 126.7 minutes, and then raise the temperature of the product to 55°C at a heating rate of 5°C / h, it takes 660 minutes;

[0062] Keep warm for 280min at a temperature of 55°C, then turn off the vacuum pump and turn off the electric heating;

[0063] Press the plug and take it out of the box to obtain the finished product of erythromycin lactobionate.

[0064] The present embodiment process takes 1324.7min.

[0065] The present invention adopts the detection method in embodiment 1 to detect the quality of the ...

Embodiment 3

[0067] Turn on the freeze dryer to cool down the temperature of the freeze-drying box to 8°C, push the glass bottle containing the liquid medicine into the vacuum freeze-dryer, and lower the temperature of the product to -45°C at a cooling rate of 5°C / h, which takes 636 minutes , and then turn on the vacuum pump;

[0068] Turn on the electric heating, turn off the refrigeration unit, raise the temperature of the product to about 0°C at a heating rate of 10°C / h, and take 270 minutes, and then raise the temperature of the product to 40°C at a heating rate of 8°C / h, and take 300 minutes;

[0069] Keep warm for 350min at a temperature of 53°C, then turn off the vacuum pump and turn off the electric heating;

[0070] Press the plug and take it out of the box to obtain the finished product of erythromycin lactobionate.

[0071] The present embodiment process takes 1556min.

[0072] The present invention adopts the detection method of embodiment 1 to detect the quality of the eryth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com