Bio-trickling device and waste gas treatment system

A technology of biological trickling filtration and waste gas inlet, which is used in gas treatment, air quality improvement, separation methods, etc., can solve the problems of complex implementation process, poor treatment effect, secondary pollution, etc. The effect of secondary pollution and waste gas degradation conversion rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

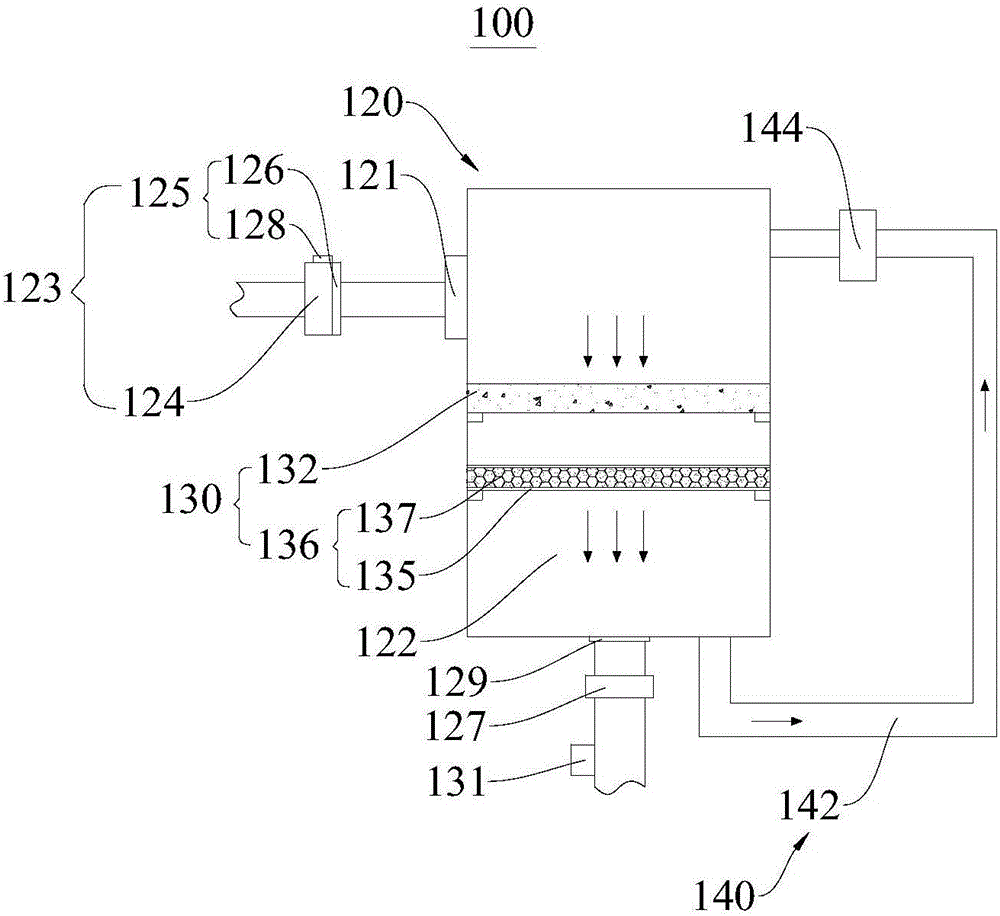

[0030] Please refer to figure 1 , this embodiment provides a biotrickling filter device 100 , which includes a biotrickling filter body 120 and a circulation transmission system 140 . Wherein, the bio-trickling filter body 120 is the main device for waste gas treatment, and the circulation transmission system 140 communicates with both ends of the bio-trickling filter body 120, so that the bio-trickling filter body 120 can cyclically degrade the waste gas, improving the efficiency of the bio-trickling filter device 100. Conversion rate of waste gas treatment.

[0031] Specifically, continue to refer to figure 1 The two ends of the bio-trickling filter body 120 are respectively provided with a waste gas inlet 121 and a degradation gas outlet 129, and a cavity 122 is arranged inside, and the waste gas inlet 121 and the degradation gas outlet 129 are both connected to the cavity 122. It should be noted that the waste gas enters the cavity 122 from the waste gas inlet 121 , unde...

no. 2 example

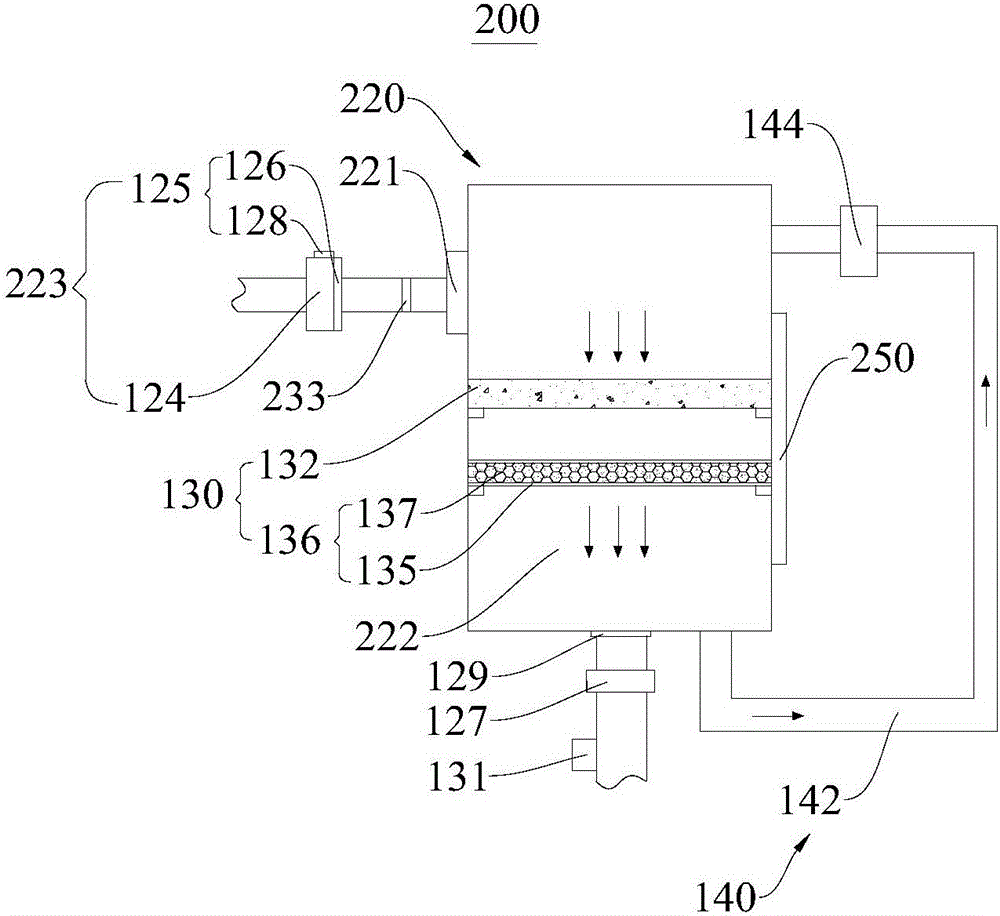

[0043] Please refer to image 3 , this embodiment provides a bio-trickling filter device 200, which is substantially the same as the bio-trickling filter device 100 provided in the first embodiment, the difference is that the bio-trickling filter device 200 provided in this embodiment is at the waste gas inlet 221 An activated carbon adsorption layer 233 is also provided.

[0044] Further, an activated carbon adsorption layer 233 is provided at the waste gas inlet 221 and placed between the first valve 223 and the cavity 222 to make the waste gas treatment effect of the biological trickling filter device 200 better. It should be noted that the activated carbon adsorption layer 233 is arranged before the exhaust gas enters the cavity 222, mainly for the first pretreatment and adsorption of the exhaust gas, and its main adsorption objects are sulfur dioxide and nitrogen oxides, etc., which makes the biological trickling filter 200 The exhaust gas treatment capacity is further i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com