Lead-free uviol glass and preparation method thereof

A technology of ultraviolet light and glass, which is applied in the field of lead-free ultraviolet transparent glass and its preparation, can solve the problems of low transmittance, failure to meet the use requirements, and high requirements for visible light transmittance, and achieve low melting point, high yield, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] formula:

[0032]

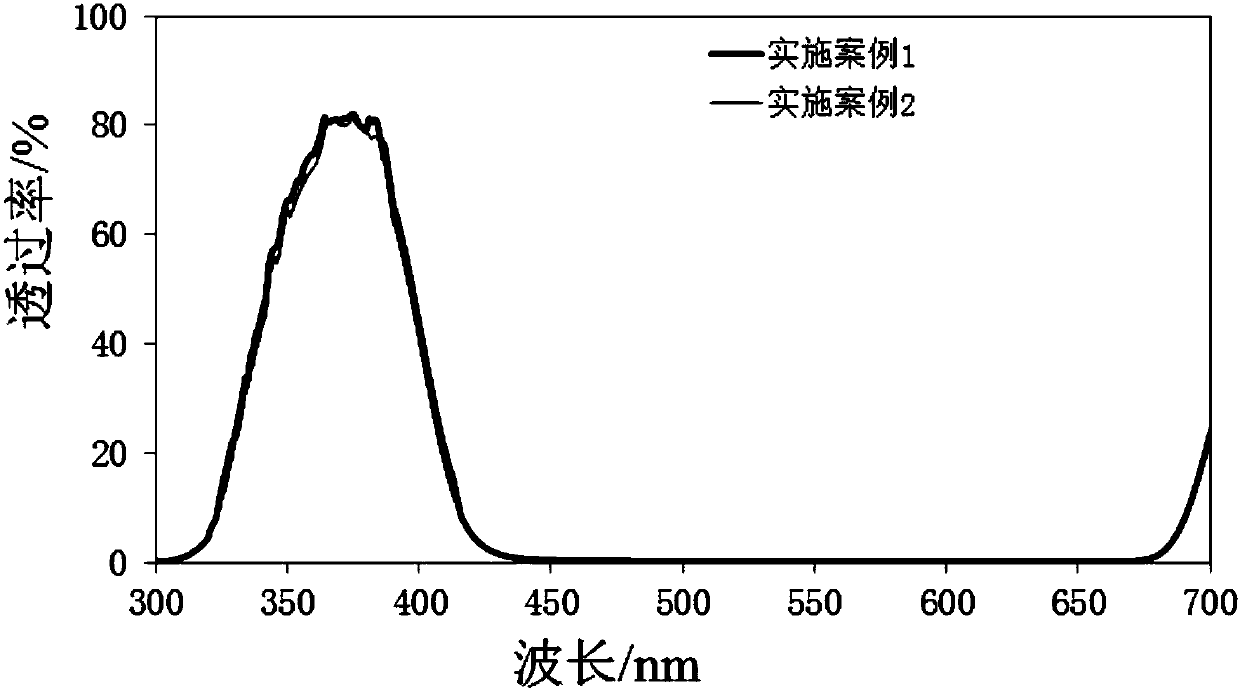

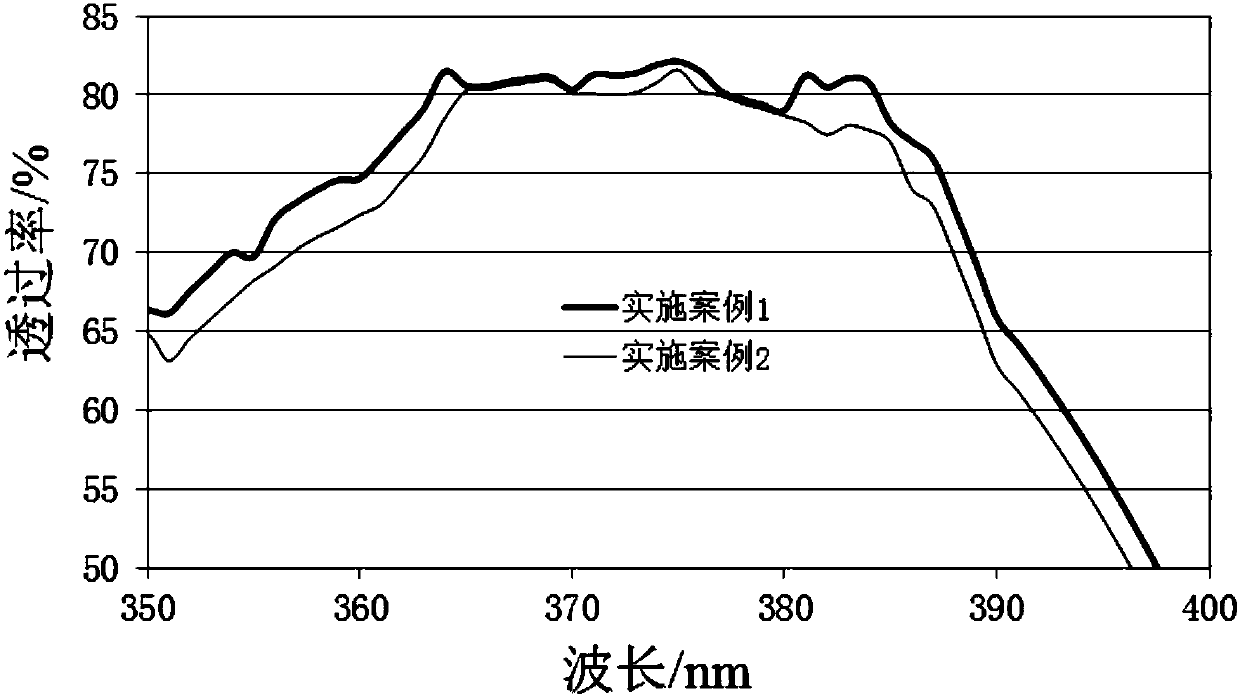

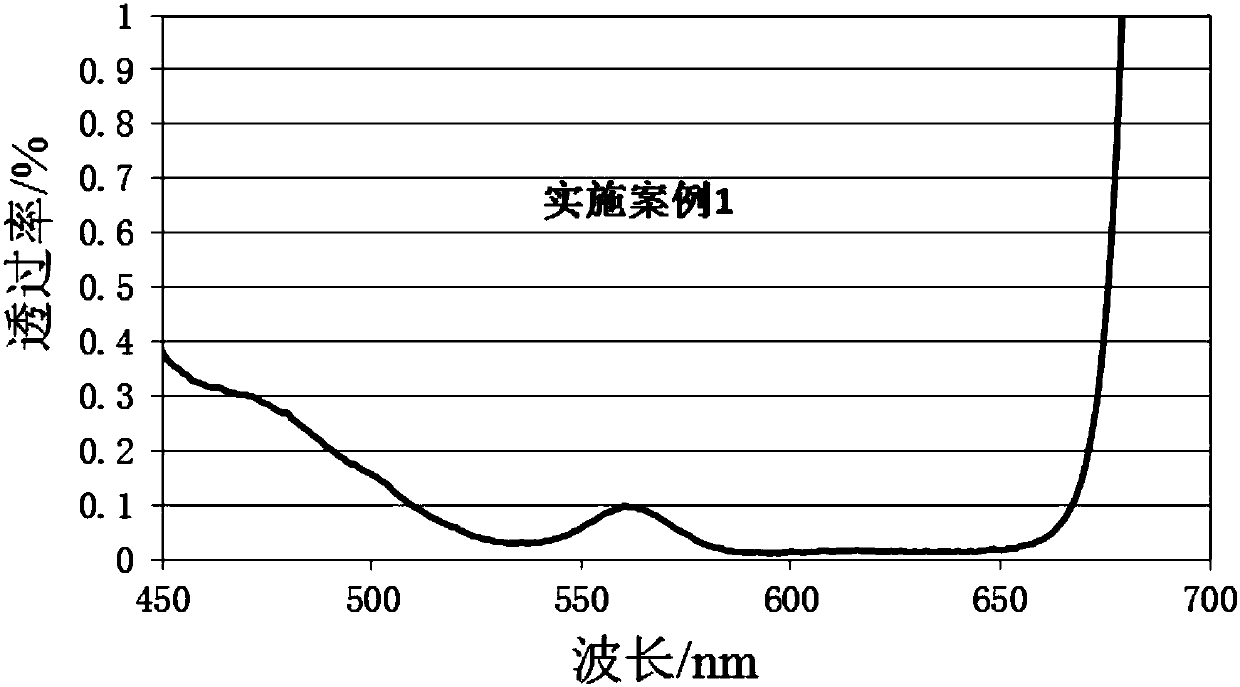

[0033] The glass batch prepared according to the above formula was melted at 1480°C for 10 hours in an electric-assisted melting furnace or an all-electric furnace, and a lead-free UV-transparent glass tube was prepared by using the horizontal tube drawing technology. The glass tube has 365nm UV-transmission The rate reaches 82.1%, the visible light transmittance is lower than 0.8%, and the lead content is lower than 450ppm. The expansion coefficient of the glass tube is 91*10 -6 / °C, the softening point temperature is 635°C.

Embodiment 2

[0035] formula:

[0036]

[0037] The glass batch prepared according to the above formula was melted at 1440°C for 6 hours by using an electric-assisted melting furnace or an all-electric melting furnace, and a lead-free UV-transparent glass tube was prepared by using a vertical tube drawing technology. The glass The tube has a 365nm ultraviolet transmittance of 80.2%, a visible light transmittance of less than 1%, and a lead content of less than 500ppm. The expansion coefficient of the glass tube is 98*10 -6 / °C, the softening point temperature is 610°C.

Embodiment 3

[0039] formula:

[0040]

[0041] The glass batch prepared according to the above formula was melted at 1460°C for 6 hours by using an electric-assisted melting furnace or an all-electric melting furnace, and a lead-free UV-transparent glass tube was prepared by using a vertical tube drawing technology. The glass The tube has a 365nm ultraviolet transmittance of 85.0%, a visible light transmittance of less than 0.8%, and a lead content of less than 400ppm. The expansion coefficient of the glass tube is 95*10 -6 / °C, the softening point temperature is 618°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com