Powder for high-strength zirconia sintered body and application of high-strength zirconia sintered body

A technology of zirconia and sintered body, applied in dental prosthesis, compression mold cup, dentistry, etc., can solve the problems of low strength of zirconia, poor overall texture and jade feeling, not beautiful enough, and achieve good jade feeling and excellent performance , the effect of strong denture texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

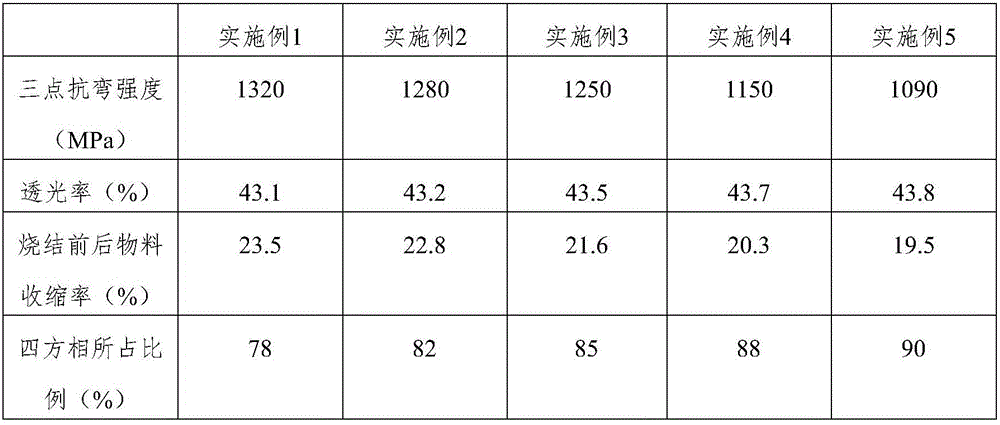

Examples

Embodiment 1

[0023] This embodiment provides a method for preparing a high-strength zirconia sintered body, which includes the following steps:

[0024] (1) Mix and dissolve soluble zirconium salt and yttrium salt in water at a molar ratio of 97.5:2.5, adjust the pH value to 9 with ammonia water under stirring conditions, then hydrothermally synthesize at 170°C for 50 hours, and wash and dry the obtained reaction solution in turn Finally, heat treatment at 950°C, and then grind, and granulate the obtained powder to obtain zirconia powder; the molar percentage of yttrium oxide in the zirconia powder is 2.5%, and the BET specific surface area of the zirconia powder is 12.8m 2 / g, the average particle size is 0.198μm;

[0025] (2) Disperse 100kg of zirconia powder in 80kg of water, add 0.4kg of acrylic acid and 2kg of polyethylene glycol, mix and spray granulate to obtain high-strength zirconia with a moisture content of 0.3wt% and an average particle size of 35 μm Powder for sintered bod...

Embodiment 2

[0028] This embodiment provides a method for preparing a high-strength zirconia sintered body, which includes the following steps:

[0029] (1) Mix and dissolve soluble zirconium salt and yttrium salt in water at a molar ratio of 97.2:2.8, adjust the pH value to 8.5 with ammonia water under stirring conditions, then hydrothermally synthesize at 160°C for 32 hours, and wash and dry the obtained reaction solution in turn Afterwards, heat treatment at 1100°C, and then grinding, and granulation of the obtained powder to obtain zirconia powder; the molar percentage of yttrium oxide in the zirconia powder is 2.8%, and the BET specific surface area of the zirconia powder is 11.6m 2 / g, the average particle size is 0.192μm;

[0030] (2) Disperse 50kg of zirconia powder in 100kg of water, add 0.1kg of polyacrylic acid and 0.5kg of polyvinyl alcohol, mix well and spray granulate to obtain a high-strength zirconia with a moisture content of 0.15wt% and an average particle size of 38 μ...

Embodiment 3

[0033] This embodiment provides a method for preparing a high-strength zirconia sintered body, which includes the following steps:

[0034] (1) Mix and dissolve soluble zirconium salt and yttrium salt in water at a molar ratio of 97:3, adjust the pH value to 10 with ammonia water under stirring conditions, then hydrothermally synthesize at 140°C for 70 hours, and wash and dry the obtained reaction solution in turn Finally, heat treatment at 1000°C, then grinding, and granulating the obtained powder to obtain zirconia powder; the molar percentage of yttrium oxide in the zirconia powder is 3%, and the BET specific surface area of the zirconia powder is 10.5m 2 / g, the average particle size is 0.201μm;

[0035] (2) Disperse 100kg of zirconia powder in 100kg of water, add 0.2kg of polyacrylic acid and 5kg of polyvinyl alcohol, mix and spray granulate to obtain high-strength zirconia with a moisture content of 0.45wt% and an average particle size of 42 μm Powder for sintered bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bet specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com