Weather-resistant coating and preparation method thereof

A coating and coating technology, which is applied in the field of weather-resistant coating coating and its preparation for pre-laying anti-adhesive waterproof coil protection layer, can solve the problems of inability to achieve 100% continuous coverage, inability to shield ultraviolet rays, etc., and achieve improved shielding of ultraviolet rays Performance, improvement of anti-channeling performance, effect of improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Preparation of Coil Protective Coating with UV Resistance

[0021] The protective coating for coils with high UV resistance contains the following components in parts by weight:

[0022] water Deionized water 25 copies acrylic emulsion Rohm and Haas AC-261P 35 copies filler Heavy Calcium Jiangxi Guangyuan CC800 30 copies UV absorber Ciba UV Absorber 326 1.0 copies Nano Zinc Oxide Shanghai Zecheng ZEC Slurral ZNO30W 5.0 copies Dispersant DP270 1.0 copies D CF10 0.5 parts Defoamer NXZ 0.5 parts leveling agent ASE-60 0.5 parts thickener RM-8W 1.0 copies preservative MV 0.5 parts

[0023] A method for preparing a coil protection coating with high UV resistance, comprising the following steps:

[0024] (1) Accurately weigh water of the same quality as the nano-zinc oxide powder according to the formula, add half of the total mass of the dispersant and pre-mix...

Embodiment 2

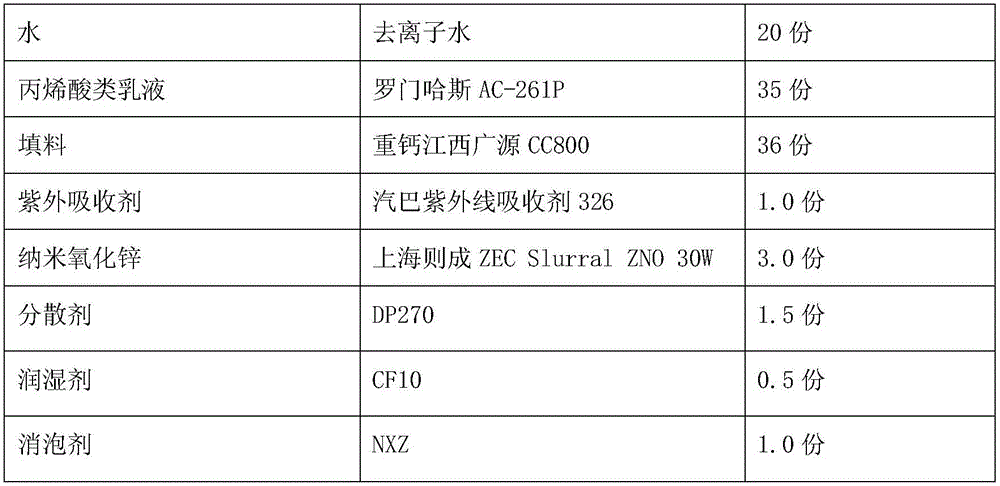

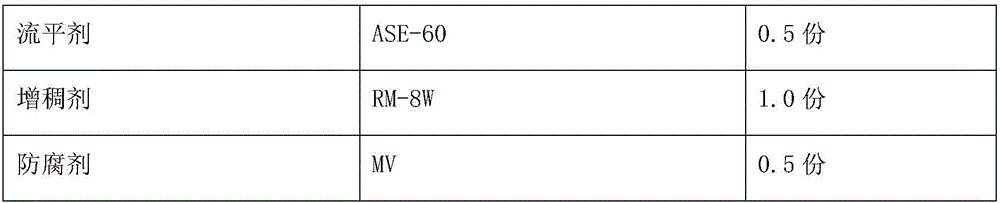

[0027] Example 2: Coil protective coating with high UV resistance

[0028] The protective coating for coils with high UV resistance contains the following components in parts by weight:

[0029]

[0030]

[0031] The preparation method of the coil protective coating with high UV resistance is the same as that in Example 1.

Embodiment 3

[0032] Example 3: Coil protective coating with high UV resistance

[0033] The protective coating for coils with high UV resistance contains the following components in parts by weight:

[0034] water Deionized water 15 copies acrylic emulsion Rohm and Haas AC-261P 30 copies filler Heavy Calcium Jiangxi Guangyuan CC800 42 copies UV absorber Ciba UV Absorber 326 2.0 copies Nano Zinc Oxide Shanghai Zecheng ZEC Slurral ZNO 30W 7.0 copies Dispersant DP270 0.5 parts D CF10 0.5 parts Defoamer NXZ 1.0 copies leveling agent ASE-60 0.5 parts thickener RM-8W 1.0 copies preservative MV 0.5 parts

[0035] The preparation method of the coil protection coating with high UV resistance is the same as that in Example 1.

[0036] The performance test results corresponding to the above embodiments are shown in Table 1.

[0037] Table 1 - performance test results of each embodiment

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com