Corrosion-resistant coating and processing method thereof

A corrosion-resistant and coating technology, applied in the field of recycled raw materials, can solve the problems of relatively high quality requirements of construction personnel, no large-scale promotion, complex construction process, etc., and achieve high solid content, strong cohesion and high mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] (1) Prepare resin solubilizer: put the measured toughening agent and diluent into the reaction kettle in turn, shear at high speed for 8 minutes, stir well, and let it stand for later use.

[0014] (2) After measuring the epoxy resin, slowly add the resin solubilizer prepared in step (1), shear at a high speed evenly, and set aside.

[0015] (3) Raise the temperature of the base asphalt to 140-145°C, slowly add the product of step (2), stir evenly, keep the temperature constant for 1 hour, then add the curing agent and filler, mechanically stir evenly, keep the temperature at 140-145°C, keep the constant temperature for 2 hours , that is, the finished corrosion-resistant coating is obtained.

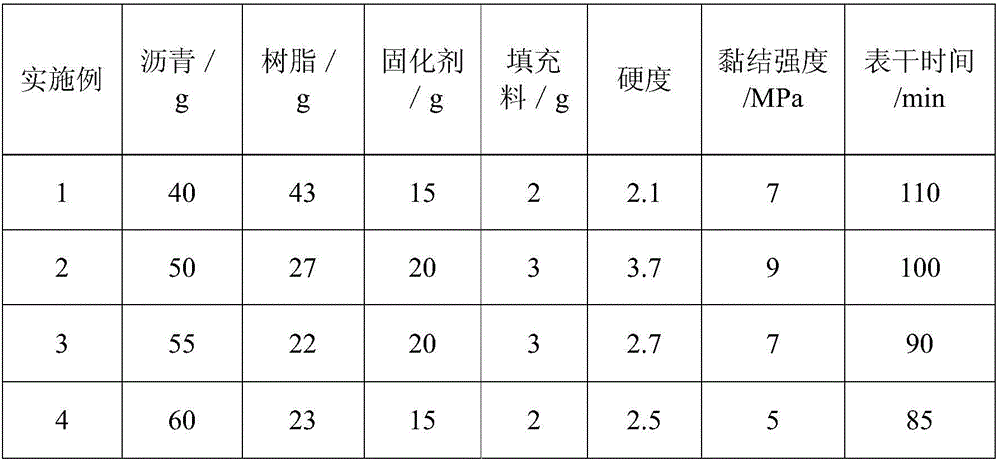

[0016] Reagents with different components were tested, and the prepared corrosion-resistant coatings all met the requirements, as shown in Table 1.

[0017] Table 1 Performance comparison table of different formulation finished products

[0018]

[0019] Through a large numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com