Rotating packed bed pyrolysis furnace and domestic waste treatment system with same

A technology of pyrolysis furnace and rotary bed, which is applied in coking ovens, steam boilers, steam generation, etc., can solve problems such as pollution, inability to get rid of dioxins, and needs to be improved, and achieve an environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The wet basis of household garbage with a moisture content of 55wt% is used as raw material, and its composition is shown in Table 1:

[0071] Table 1 Household garbage composition (wt%)

[0072] name the fabric plastic Paper wood bamboo Kitchen waste muck glass, metal total wet basis 3.53 25.96 14.94 7.44 28.91 11.58 7.64 100

[0073] The domestic waste is sent to the feeding device through the conveying system, and the feeding device feeds the material to the rotary bed pyrolysis furnace distribution plate through the feeding port. During the conveying process, large pieces of inorganic matter, such as bricks, stones, and large glass metal products, etc.;

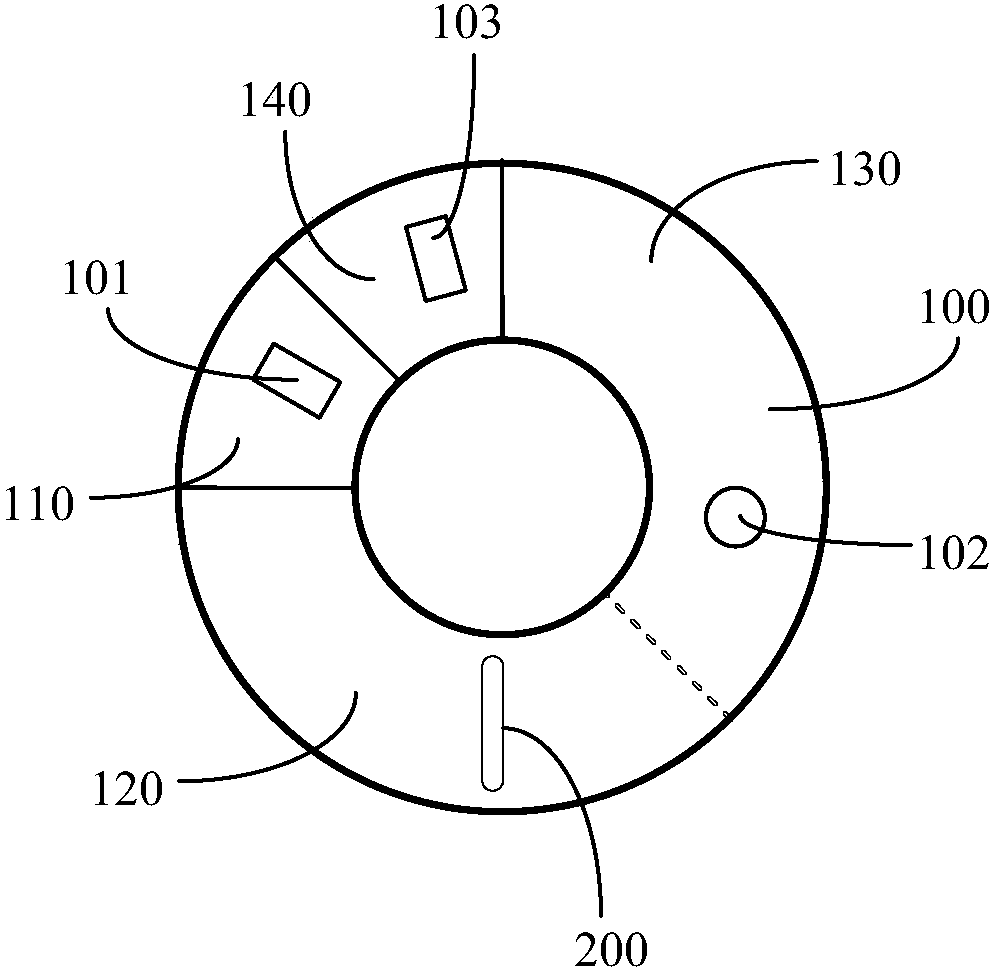

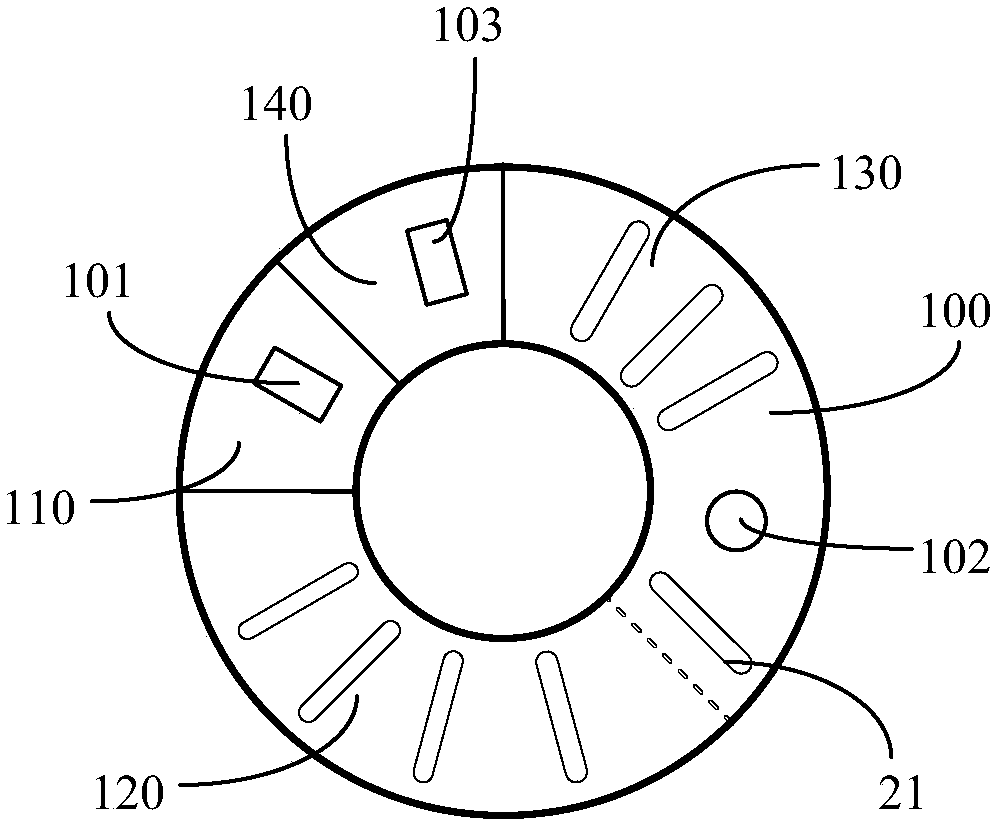

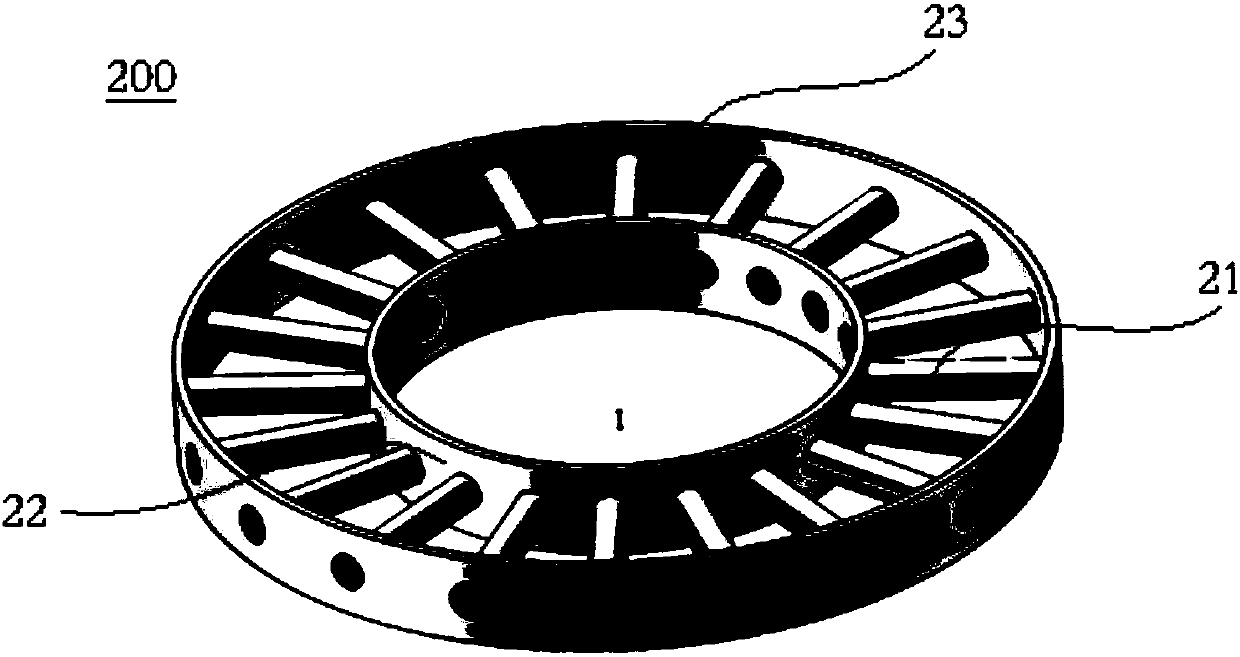

[0074] The main pyrolysis equipment is a rotary bed pyrolysis furnace with electric heating rods, which includes a rotating bed pyrolysis furnace, electric heating rods, and auxiliary mechanisms such as material distribution and discharge. The bottom of the furnace is a ...

Embodiment 2

[0083] The domestic garbage wet basis with a moisture content of 45wt% is used as raw material, and its composition is shown in Table 3:

[0084] Table 3 domestic waste composition (wt%)

[0085] name the fabric plastic Paper wood bamboo Kitchen waste muck glass, metal total wet basis 5.12 17.83 15.67 9.35 34.16 8.71 9.16 100

[0086] The domestic waste is sent to the feeding device through the conveying system, and the feeding device feeds the material to the rotary bed pyrolysis furnace distribution plate through the feeding port. During the conveying process, large pieces of inorganic matter, such as bricks, stones, and large glass metal products, etc.;

[0087] The main pyrolysis equipment is a rotary bed pyrolysis furnace with electric heating rods, which includes a rotating bed pyrolysis furnace, electric heating rods, and auxiliary mechanisms such as material distribution and discharge. The bottom of the furnace is a rotatabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com