Bioemulsifier and application thereof

A biological emulsifier and emulsifier technology, applied in biochemical equipment and methods, microorganisms, microorganisms, etc., can solve the problems of difficult to fully meet the restoration requirements, slow recovery process efficiency, secondary pollution, etc., and achieve major economic benefits and Large-scale application, good deoiling effect, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

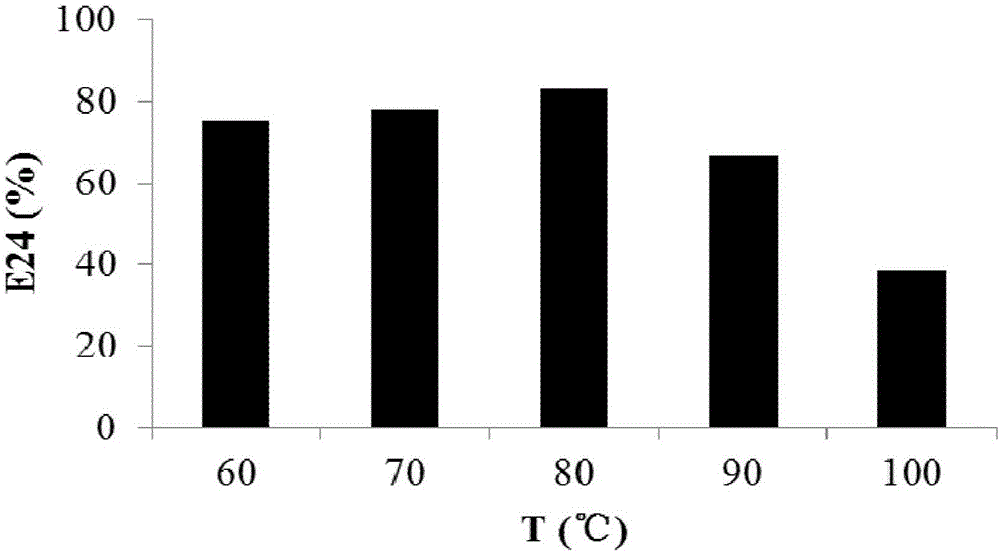

[0023] Embodiment 1: the preparation of emulsifying agent

[0024] 1) Preparation of crude extract

[0025] The active strain Geobacillus sp.XS2-450 was shaken at 60°C and 180rpm for 10 hours as a seed solution for fermentation, and the inoculation amount was 10% (v / v), inoculated into the fermentation medium, and the final concentration of 0.1 % palm oil is used as the inducer of producing highly active biological emulsifier, and the culture time of emulsifier fermented liquid is 24h, and the fermented liquid obtained is at 4 DEG C, centrifuged under the condition of 5000rpm for 30min to remove thalline, and the supernatant obtained is Crude extract of emulsifier. The crude extract was concentrated to 1 / 5 volume of the original supernatant, and stored at 4°C.

[0026] 2) Salting out treatment

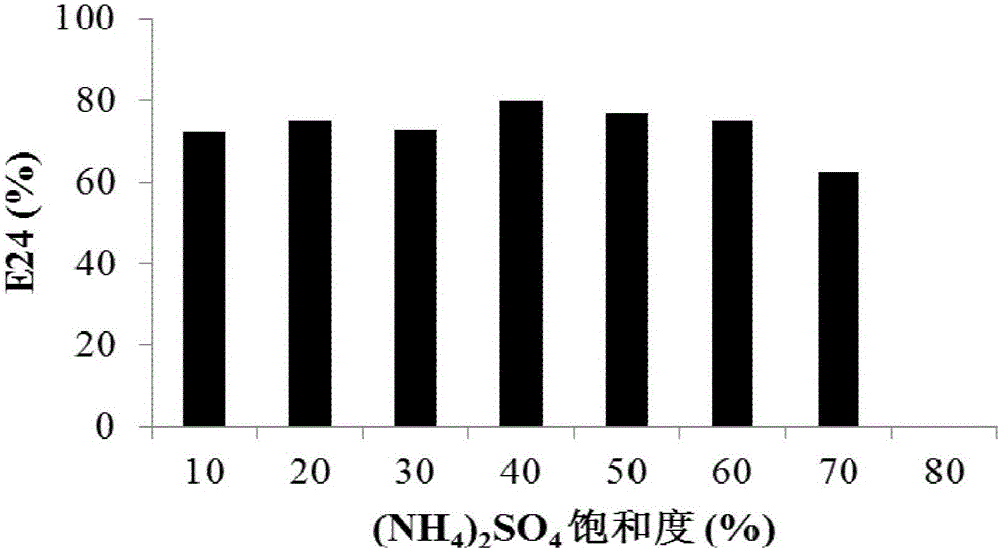

[0027] Take 20ml of the emulsifier crude extract prepared in step 1) and add ammonium sulfate particles to make it reach the saturation of 10%, 20%, 30%, 40%, 50%, 60%, 70%, 80% res...

Embodiment 3

[0037] Embodiment 3: the effect of the emulsifier prepared in embodiment 1

[0038] The present invention mainly utilizes the biological emulsifier prepared in Example 1 to treat oil sludge polluted by high viscosity and heavy hydrocarbons.

[0039] Stir the sludge to make it homogeneous, adjust the ratio of sludge and bio-emulsifier to 4:5, add water 10 times that of the sludge, stir fully at 60°C to emulsify the crude oil in the sludge, and let it stand , The settled oil residue is deeply deoiled to remove residual high-viscosity components, so as to achieve the purpose of separating the oil and residue in the sludge, and finally recover all the emulsified upper crude oil. During the treatment process, the oil content of the sludge was monitored, and the oil content in the sludge decreased from the original 26.2% to the current 1.5%, and the oil content decreased by more than 94%. Image 6 As shown, it meets the oil sludge disposal standard; compared with physical and chemica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com