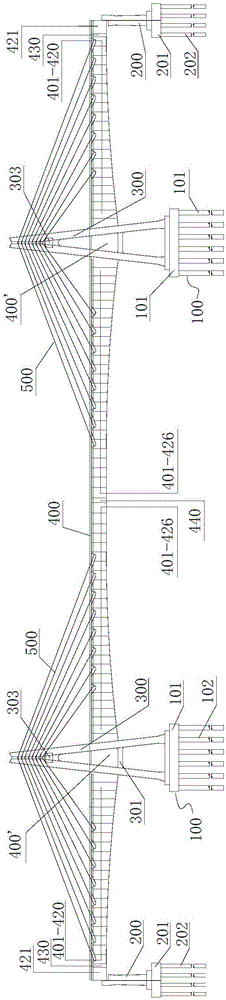

Main girder construction process for extradosed cable-stayed bridge with double towers and double cable planes

A low-tower cable-stayed bridge and construction technology technology, applied in cable-stayed bridges, bridges, bridge construction and other directions, can solve problems such as easy misalignment of joints and leakage of slurry, imbalance at both ends of the load, and many technical difficulties. To achieve the effect of simple construction, saving construction costs, and good structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

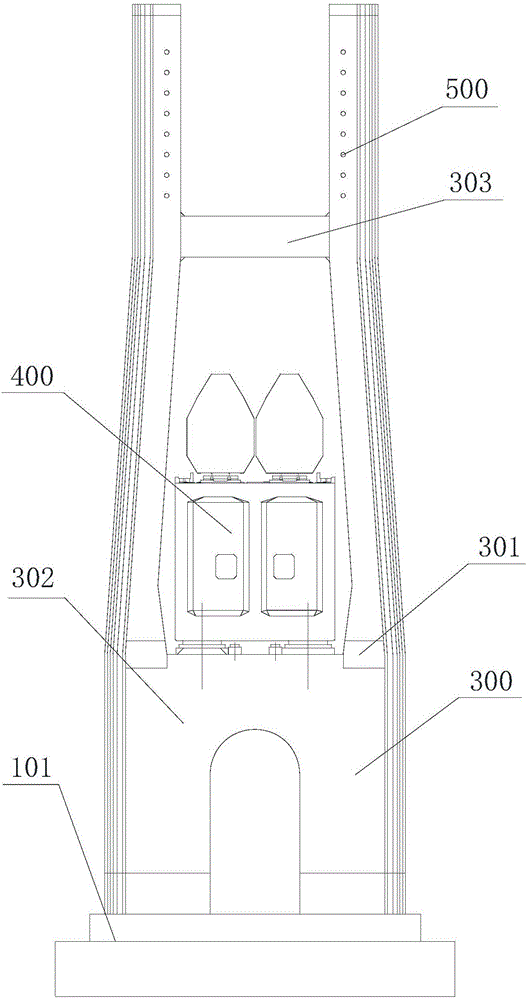

[0015] see figure 1 and figure 2 , the double-tower double-cable plane low-tower cable-stayed bridge constructed by the present invention has two main piers 100 and two side piers 200; , 201 and pile group foundations 102, 202; the bridge tower 300 on the two main piers 100 is a reinforced concrete structure; the longitudinal lower part of each bridge tower 300 has a longitudinal tie beam 301 in an "A" shape, and the transverse lower part has a portal arch The support beam 302, the upper part has an upper beam 303 in an "H" shape; each bridge tower 300 is divided into twelve sections for construction, the first section is the tower base, and the first section to the fourth section are transversely Double-arch lower tower piers, the fifth to twelfth sections are upper tower columns; the longitudinal tie beam 301 on the bridge tower 300 is located on the upper part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com