Method for realizing simultaneous sensing of temperature, strain and refractive index through single fiber bragg grating

A technology of Bragg grating and single optical fiber, which is applied in the direction of transmitting sensing components, converting sensor output, instruments, etc. with optical devices, can solve the problem of simultaneous sensing of single optical fiber sensors, and achieve good consistency and high sensing sensitivity High and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

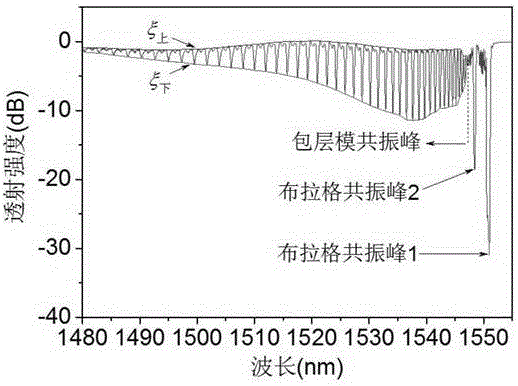

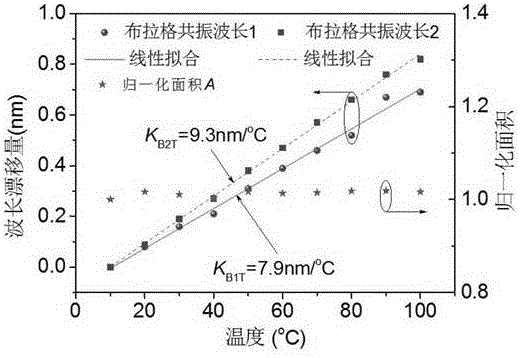

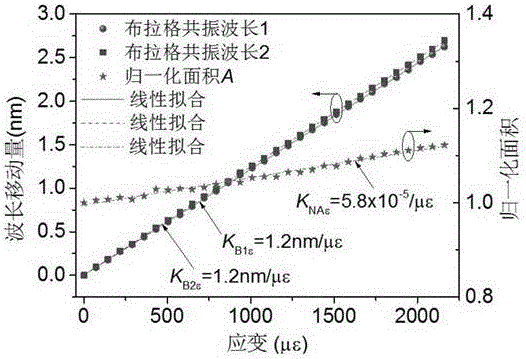

[0024] The implementation steps of using a single FBG to realize simultaneous sensing of temperature, strain and refractive index are as follows: figure 1 Shown:

[0025] Step 1: Writing FBGs in few-mode fibers using femtosecond laser and phase mask method

[0026] The schematic diagram of the optical path for writing FBG in few-mode fiber by femtosecond laser and phase mask method is as follows figure 2 shown. A femtosecond laser with a center wavelength of 800 nm, a pulse width of 35 fs, a repetition frequency of 1 KHz and a beam diameter of 8 mm is generated by the femtosecond laser 1 . The half-wave plate 2 and the polarizer 3 are sequentially placed in the optical path to adjust the intensity of the femtosecond laser, so that the intensity of the femtosecond laser is 700 μJ. The femtosecond laser is focused by a plano-convex cylindrical lens 4 with a fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com