Spiral light microflow sensor

A helical, sensor technology, applied in the field of optical sensors, can solve the problems of the influence of the light signal used for spatial stability sensing, and the sensitivity needs to be further improved, and achieve a compact structure, good temperature stability and space stability, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

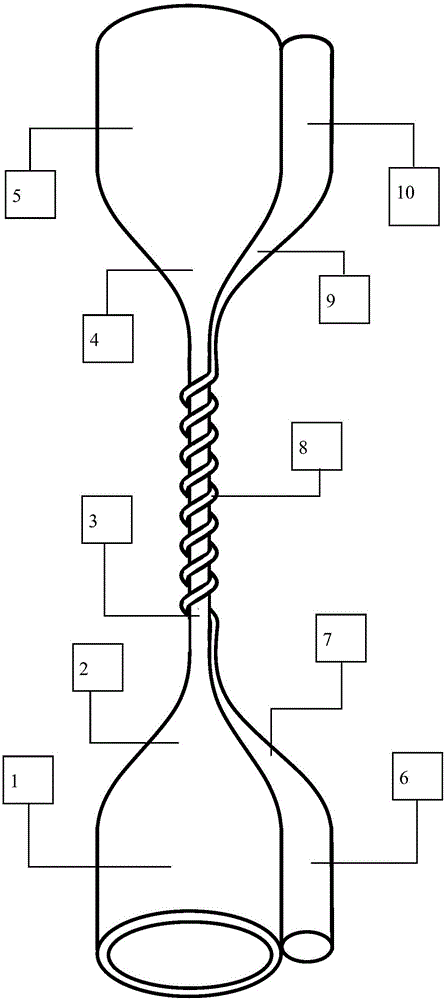

[0024] figure 1 It is a structural schematic diagram of a spiral optical microflow sensor disclosed by the present invention, such as figure 1 As shown, a spiral optical microfluidic sensor, the optical fiber and the quartz capillary are respectively removed from the coating layer and then melted to form a micro-nano optical fiber and a micro-nano quartz capillary with a certain size, and the micro-nano optical fiber is wound on the micro-nano quartz Capillary, a periodic structure formed.

[0025] The structure of the micro-nano quartz capillary includes a first quartz capillary end zone 1, a second quartz capillary end zone 5, a first micro-nano quartz capillary cone zone 2, a second micro-nano quartz capillary cone zone 4 and a micro-nano quartz capillary uniform zone 3 ,

[0026] The structure of the micro-nano fiber includes a first fiber end region 6, a second fiber end region 10, a first micro-nano fiber taper region 7, a second micro-nano fiber taper region 9 and a m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap