Method for using tailings mold bag wall to fill ore pillar recovery under pit

A technology for underground and mold pocket walls, which is used in fillings, mining equipment, earth-moving drilling, etc., can solve problems such as unreasonable methods and low efficiency, and achieve the effects of convenient material selection, small limitations, and increased good contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

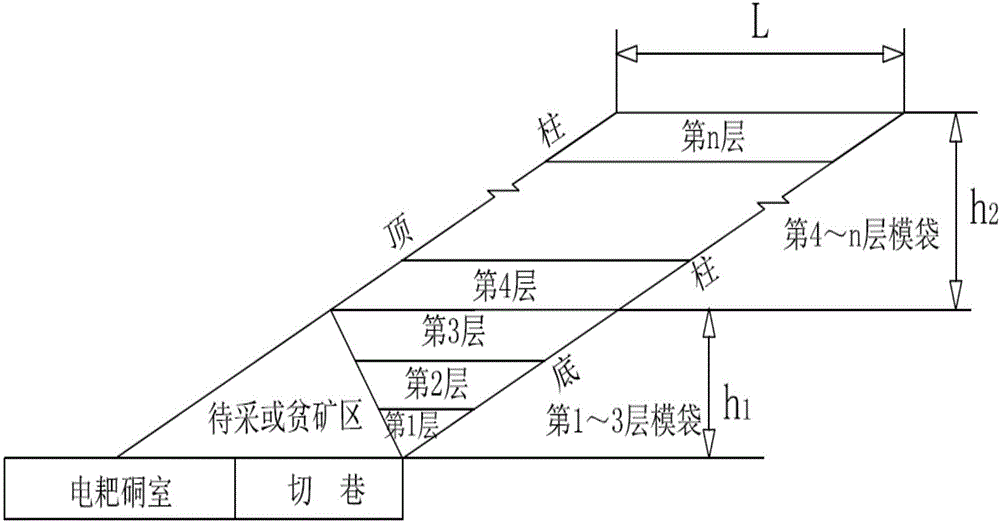

[0046] Such as figure 1 As shown, a kind of method that uses tailings mold bag wall filling back mining pillar under the mine that the present invention provides, comprises the following steps:

[0047] Step 1: According to the distance between two ore pillars, the relationship between the size of the ore body settlement and the load capacity of the mold pocket wall, calculate the compression amount S of the mold pocket wall. The specific calculation steps are as follows:

[0048] 1) Calculate the relative density Dγ:

[0049]

[0050] In formula (1), Dγ: relative density, e max- : maximum void ratio, e min : minimum void ratio, e 0 : natural void ratio or relative void ratio of tailings;

[0051] 2) Calculate the amount of compression Δs:

[0052]

[0053] In formula (2), Δs: the compression amount of tailings in any horizontal layer Δz, Δz—layer thickness, e 1 ---The void ratio of the soil in the natural state, e 2 ---The void ratio of the compacted soil;

[00...

Embodiment 2

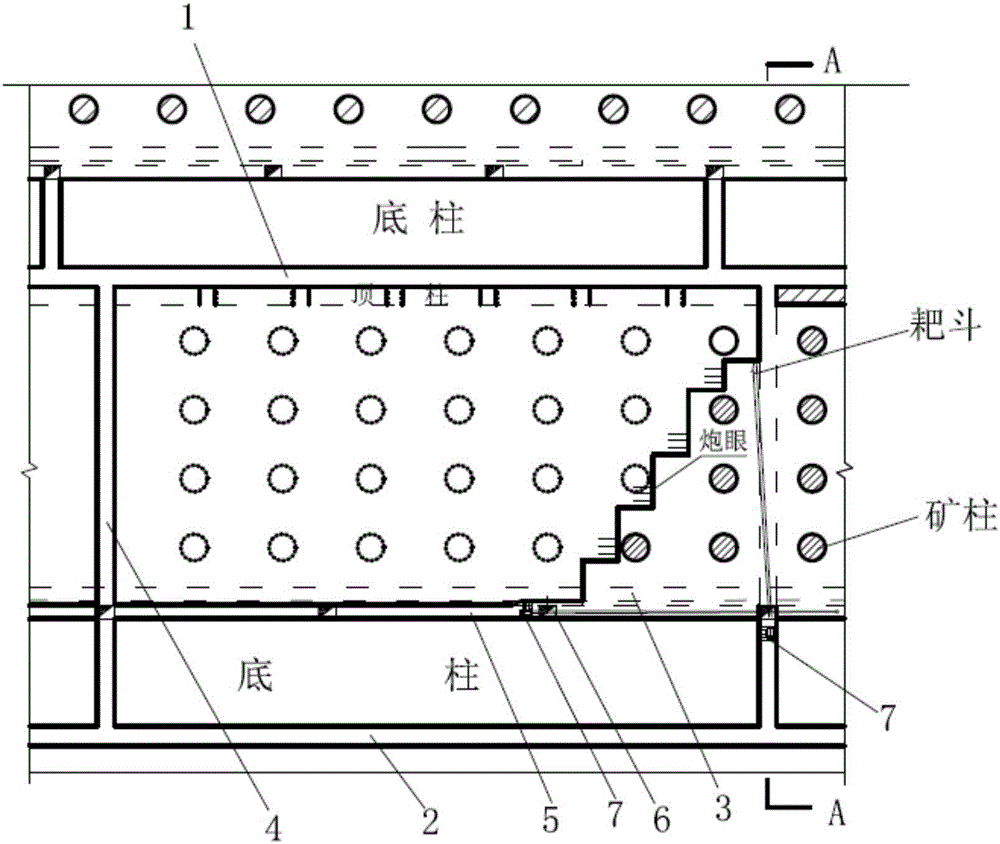

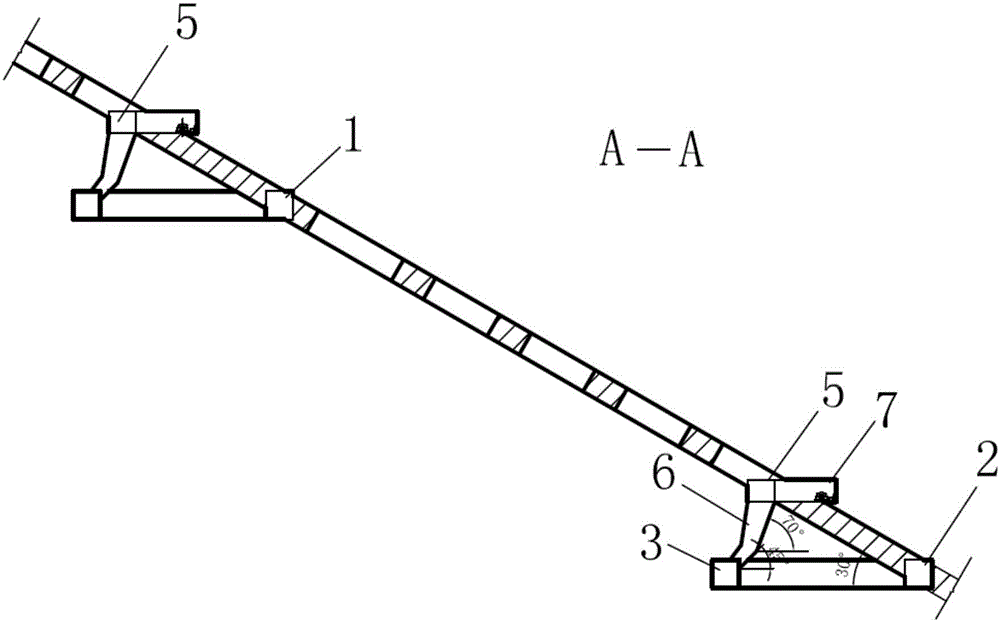

[0064] This embodiment is further improved on the basis of Embodiment 1, the difference is that the method provided by the present invention is to use the tailings mold bag wall to fill back the mining pillar under the mine, such as Figure 1-5 As shown, the ore pillars in the stope are arranged in parallel along the ore body tendency. During the mining stage, they are mainly used for the mining of the ore pillars under the mine. After the ore mined in the mine is transported out, several regularly arranged ore Generally, the horizontal distance between the two ore pillars is 7 meters, the average oblique length of the mine house is 50m, and the diameter of the ore pillar is 3 meters, 8-20m 3 A blast hole is set on the ore pillar for blasting, a rake bucket is arranged near the blast hole, a cutting lane 5 next to the mine bottom roadway 3, the rake bucket is set opposite to the bucket opening 6 on the mine bottom roadway 3, and the cutting roadway 5 is connected to the electri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com