Medical silicone gel tape and preparation method thereof

A technology of silicone gel tape and silicone gel, which is applied to the material or device of bandages, absorbent pads or surgical supplies, and dressing fields, can solve the problems of difficult fit, poor air permeability, etc., and achieves good fit and structure. Uniform and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

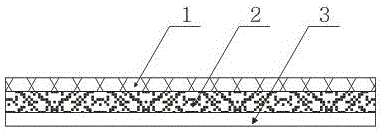

[0025] The present embodiment is a medical silicone gel tape, combined with figure 1 , including the non-woven layer 1, the silicone gel layer 2 and the release substrate 3, the non-woven layer 1, the silicone gel layer 2 and the release substrate 3 are arranged in order from top to bottom, and the silicone gel layer 2 It is formed by compounding semi-solid silicone gel on the non-woven fabric layer 1, and the release substrate 3 is attached to the silicone gel layer 2; when in use, the release substrate 3 is peeled off, and the silicone gel layer 2 is directly attached on the skin.

[0026] Among them, in this embodiment, the release substrate 3 is a fluorine release film with a thickness of 0.1 mm, and the amount of silicone gel glue is 100 g / m 2 , the non-woven fabric is spunlace non-woven fabric, the thickness is 35g / m 2 .

[0027] Step A: Apply the silicone gel to the release surface of the fluorine release film on the gluing machine according to the above amount of gl...

Embodiment 2

[0032] The setting and working principle of this example are the same as those of Example 1. The difference is that the release substrate 3 is a fluorine release film, with a thickness of 0.1 mm and a silicone gel gluing amount of 75 g / m. 2 , the non-woven fabric is spunlace non-woven fabric, the thickness is 40g / m 2 .

[0033] Step A: Apply the silicone gel to the release surface of the fluorine release film on the gluing machine according to the above amount of glue;

[0034] Step B: the first oven heating, the oven temperature is set to 65°C, and the heating time is 2min;

[0035] Step C: compound the non-woven fabric to the surface of the silicone gel;

[0036] Step D: the second oven heating, the oven temperature is set to 110 ° C, the heating time is 4 minutes, and finally the roll is wound and cut into corresponding specifications.

Embodiment 3

[0038] The setting and working principle of this example are the same as those of Example 1, the difference is: the release substrate 3 is a fluorine release film, the thickness is 0.1mm, and the amount of silicone gel glue is 150g / m 2 , the non-woven fabric is spunlace non-woven fabric, the thickness is 30g / m 2 .

[0039] Step A: Apply the silicone gel to the release surface of the fluorine release film on the gluing machine according to the above amount of glue;

[0040] Step B: the first oven heating, the oven temperature is set to 100°C, and the heating time is 1.5min;

[0041] Step C: compound the non-woven fabric to the surface of the silicone gel;

[0042] Step D: the second oven heating, the oven temperature is set to 130 ° C, the heating time is 4 minutes, and finally the roll is wound and cut into corresponding specifications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com