Patents

Literature

60results about How to "Adapt to industrial mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

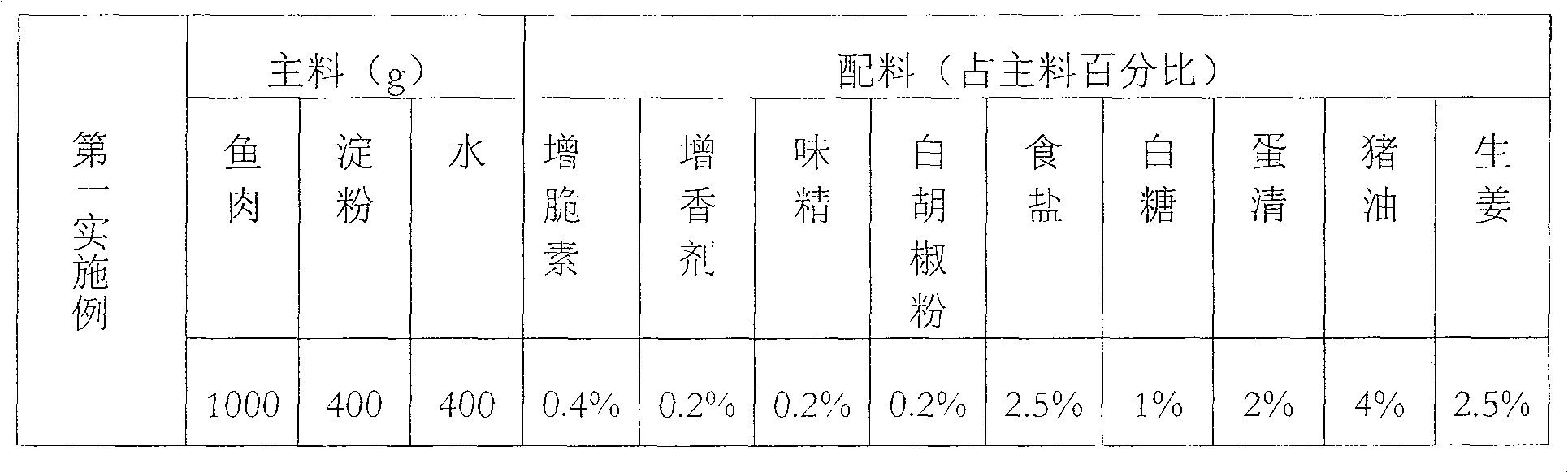

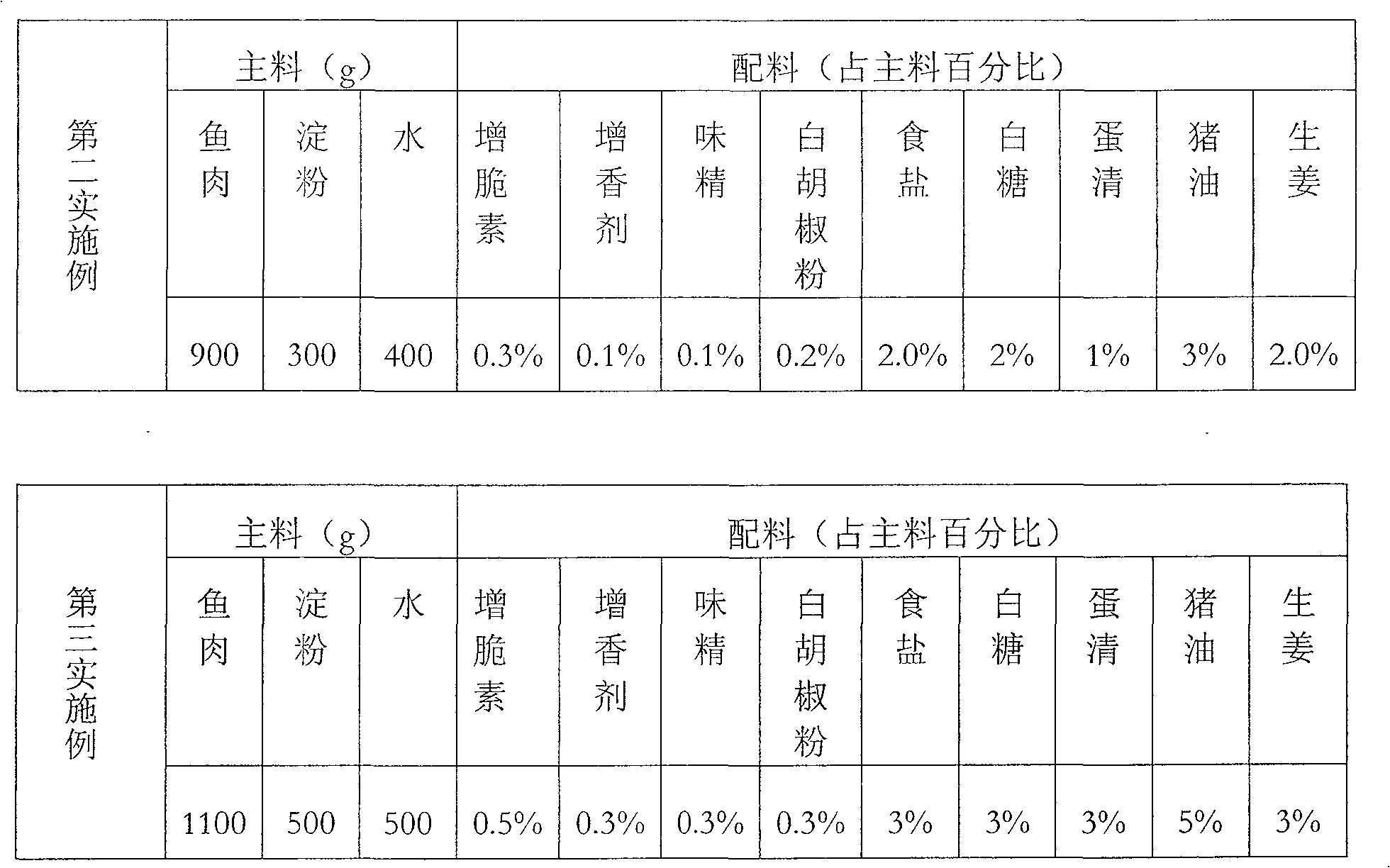

Fish noodle and production method thereof

The invention relates to a fish noodle comprising major ingredients and minor ingredients, the major ingredients include fish 800-1000 parts, starch 300-500 parts, water 300-500 parts, the minor ingredients include the following raw materials (by weight ratio of the major ingredients): 0.3-0.5% of crisp enhancer, 0.1-0.3% of flavoring agent, 0.1-0.3% of gourmet powder, 2-3% of table salt, 1-3% of white sugar, 3-5% of lard, 2-4% of fresh ginger, 0.1-0.3% of pepper powder, 1-3% of egg white. The process for preparing the noodle consists of preliminary treatment, collecting meat, cooling down through refrigeration, making fish glue, mixing, stirring, forming, shaping, cooling down and packaging.

Owner:卢建中

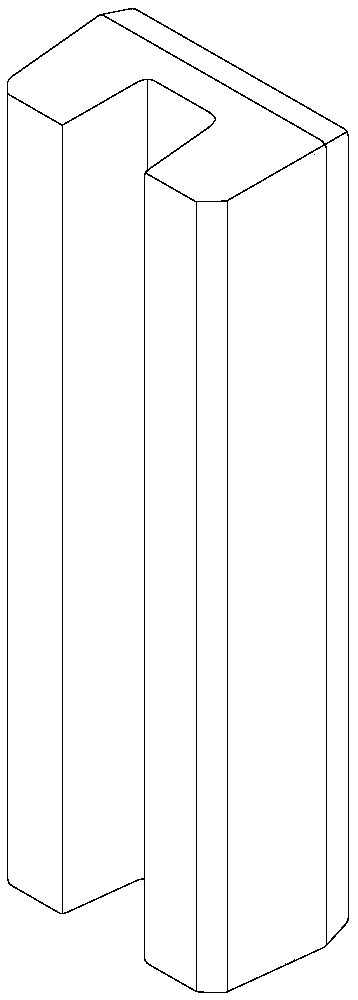

One-die-multi-part forging process of groove-shaped part

InactiveCN108723269AHigh strengthImprove toughnessMetal-working apparatusMedium frequencyHeating furnace

The invention relates to a one-die-multi-part forging process of a groove-shaped part. The one-die-multi-part forging process comprises the following steps of 1, blanking process; 2, heating process;3, pre-forging process; 4, final forging process; 5, final forging process; 6, shot blasting process; and 7, sawing process. In the step 1, a metal disc saw is used for sawing round bar materials; inthe step 2, a medium-frequency heating furnace is used for carrying out heating treatment on the round bar materials cut off by the saw; in the step 3, upsetting treatment is carried out on the heatedround bar materials by an air hammer, the oxide skin on the surface of the round bar materials is removed, and the blank is upset until the sectional area is the same as the sectional area of a part;in the step 4, final forging treatment is carried out on the pre-forged blank by a hot die forging press, and the size of the part after the part is formed is consistent with the requirement of the drawing; in the step 5, the final forging part is subjected to edge cutting treatment by an open-type inclinable press; in the step 6, shot blasting is carried out on the cut part by using a crawler-type shot blasting machine; and in the step 7, the sawing process is carried out on the part subjected to shot blasting treatment through a band sawing machine, and finally the groove-shaped part is obtained. The production cost of the forging process is reduced, and the prepared groove-shaped part is high in strength and good in toughness.

Owner:CHANGZHOU SHUANGQIANG MASCH MFG CO LTD

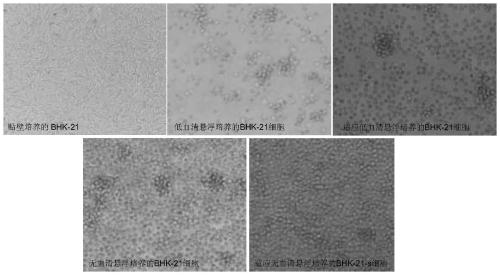

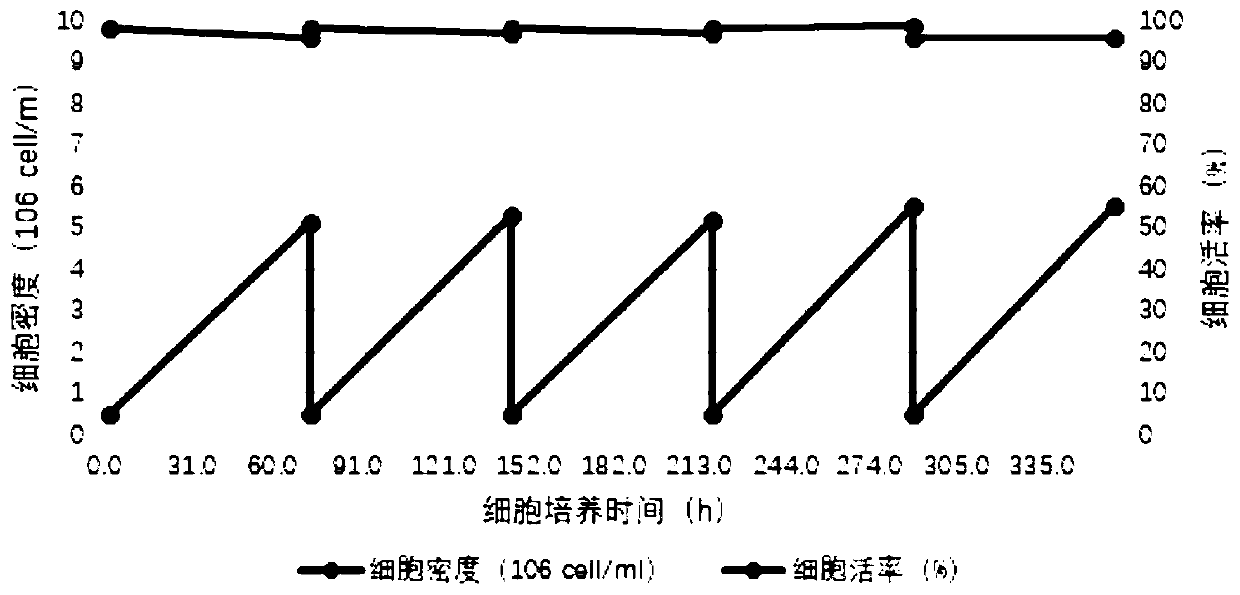

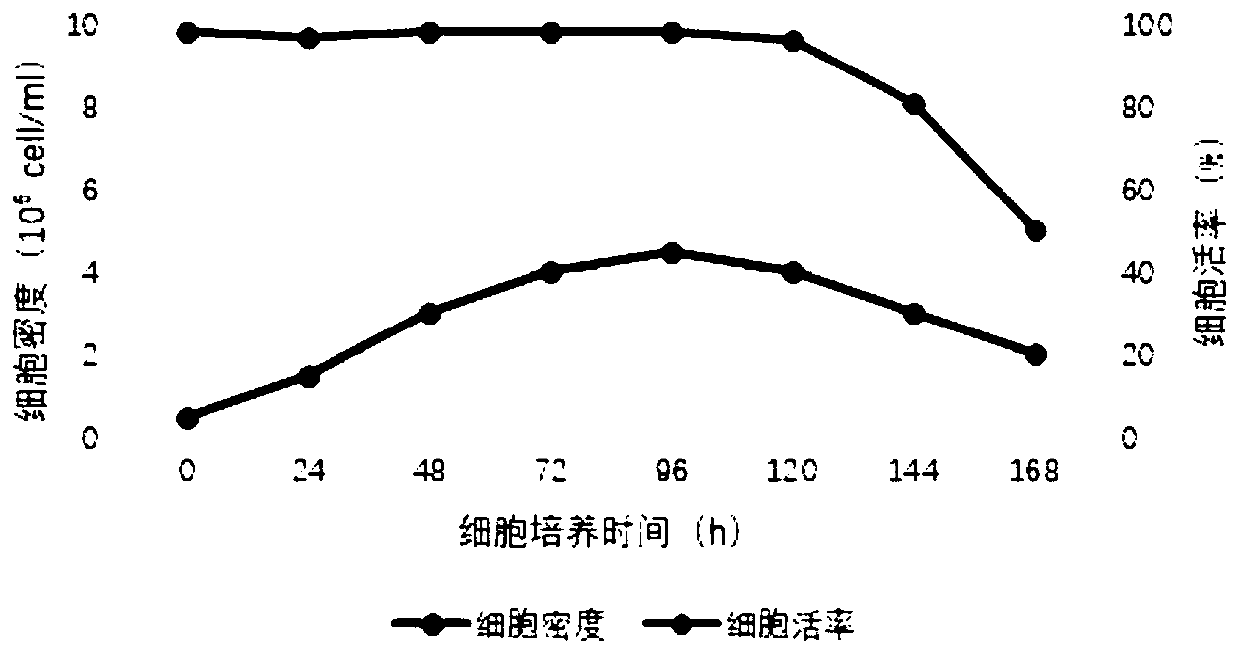

BHK-21-SC cell strain adapted to serum-free suspension culture and method for preparing vaccine antigen with cell strain

InactiveCN110093307AFast growthImprove shear resistanceSsRNA viruses negative-senseViral antigen ingredientsGolden hamsterVaccine antigen

The invention discloses a BHK-21-SC cell strain adapted to serum-free suspension culture and a method for preparing a vaccine antigen with the cell strain. The BHK-21-SC cell strain is a juvenile golden hamster kidney cell strain, and has the preservation number of CGMCC No.16817. The cell strain is cultured according to the initial cell density of 0.5-0.6*10<6> cell / ml. 72 hours later, the cellsgrow to the cell density of 8-10*10<6> cell / ml. The screened and domesticated BHK-21 cell strain adapted to serum-free full suspension culture is used for production of a high-titer Newcastle diseasevirus solution, and a domestication process for preparation of Newcastle disease virus by the BHK-21 cell strain adapted to serum-free suspension culture is established.

Owner:BEIJING VBIOSCI INC +1

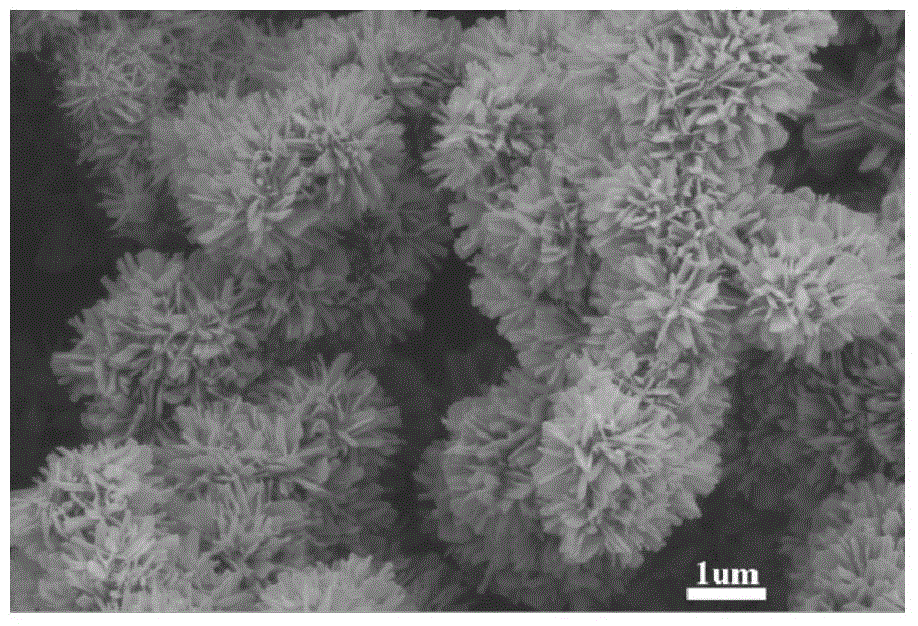

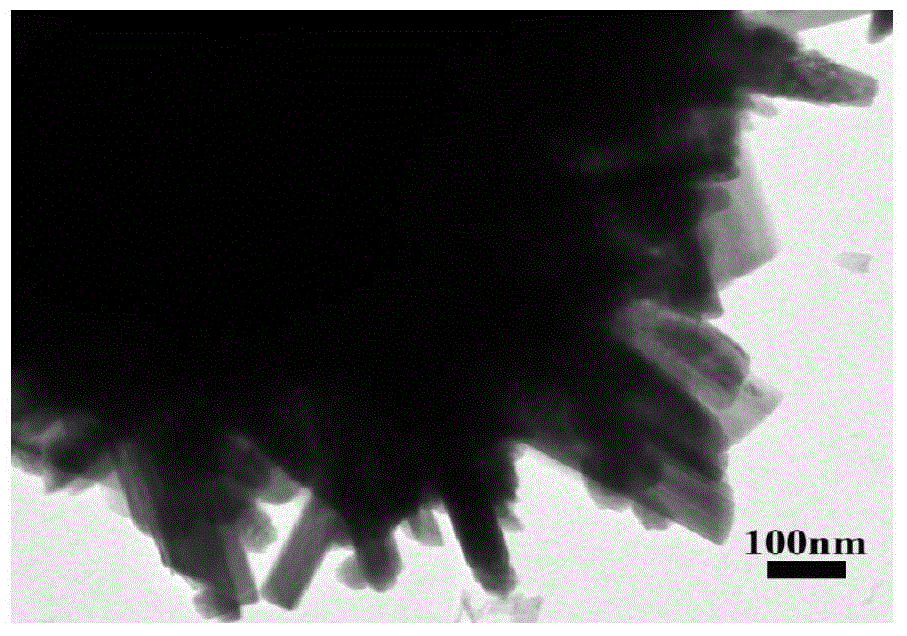

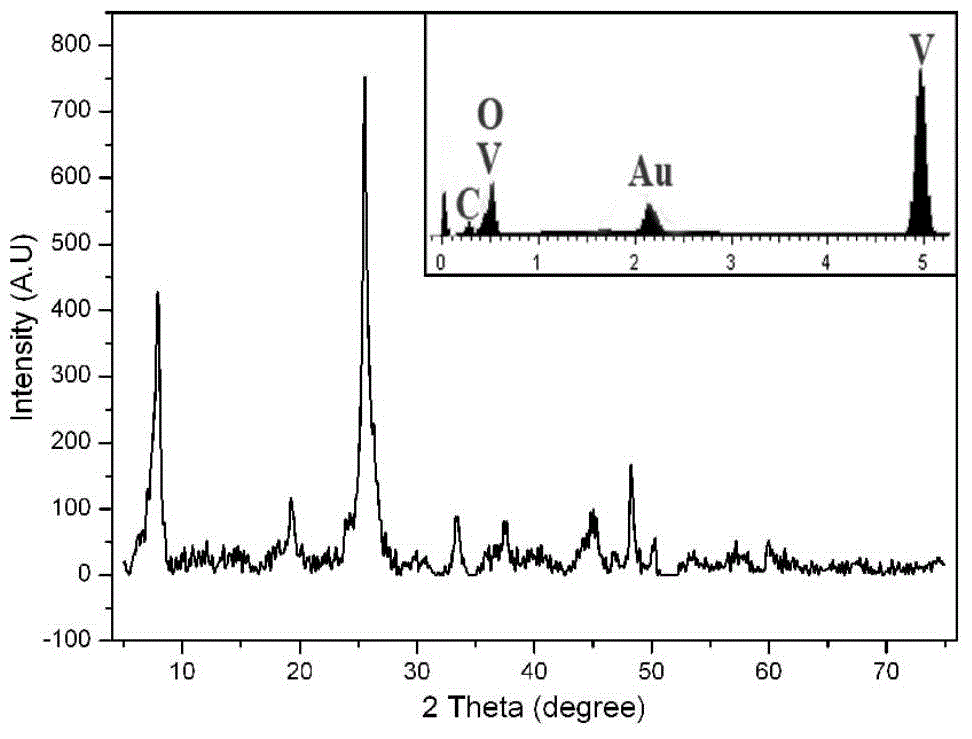

Method for preparing urchin-like vanadium base nanometer electrode material and application of the material

ActiveCN104658771AOmit removal stepStrong controllabilityMaterial nanotechnologyHybrid capacitor electrodesWater bathsSurface-active agents

The invention discloses a method for preparing an urchin-like vanadium base nanometer electrode material and application of the material. The method comprises the steps of adding vanadium pentoxide into aqueous hydrogen peroxide, and performing electromagnetic stirring in water bath to prepare a vanadium precursor solution; taking the vanadium precursor solution, ethylene glycol and deionized water and adding ammonium sulfate, controlling the solution within Ph2.0-3.0, performing electromagnetic stirring to mix the solution, and transferring the solution to a hydrothermal reaction kettle to perform hydrothermal reaction for 5-48h at 160-200 DEG C; centrifuging, washing and drying to prepare the electrode material. The invention further discloses a method for preparing an electrode plate, and the method is characterized in that the urchin-like vanadium base nanometer electrode material is mixed with a binder and a conductive agent according to the weight proportion of (70-80) to (0-10) to 10 and a current collector is coated with the mixture. According to the method, V205 with the relatively low price is regarded as a vanadium source without any surface active agent; the preparation process is simple, efficient, steady and economic, the morphology change of the material is slightly affected by heat treatment, and the prepared urchin-like vanadium base nanometer electrode material has high specific capacity and long cycling life in water electrolyte and organic electrolyte.

Owner:CHONGQING UNIV

Membrane filtration technology for preparing xylitol from viscose fiber squeezed alkali solution

InactiveCN104402676AAvoid damageLow running costOrganic compound preparationHydroxy compound preparationHydrolysateImpurity

The invention provides a membrane filtration technology for preparing xylitol from viscose fiber squeezed alkali solution. The technology is characterized by comprising the following steps: step A, membrane condensation: pre-filtering squeezed liquid generated during the viscose fiber production process so as to remove the large particle impurities, cyclically condensing the filtrate by a nano-filter membrane for 2 to 4 times, and transferring the last concentrate to a diffusion-dialysis cation exchange membrane stack so as to obtain the concentrate namely the concentrate of squeezed liquid, wherein the nano-filter membrane cyclic concentration is performed for 2 to 4 times, and before each filtration, the liquid should be diluted by water before being filtered by the nano-filter membrane; step B, semi-fiber extraction: adding acid into the concentrate of the squeezed alkali liquid to neutralize the concentrate so as to obtain a semi-fiber solution; step C, hydrolysis: adding diluted sulfuric acid into the obtained semi-fiber solution to carry out hydrolysis reactions; step D, purification: filtering the hydrolysate by a ceramic membrane, then filtering the filtrate by a nano-filter membrane to remove the salts, decoloring the concentrate by active carbon to obtain a purified solution of xylose; step E, hydrogenation: introducing hydrogen gas into the purified solution of xylose to carry out hydrogenation reactions in the presence of a catalyst namely nickel so as to obtain the xylitol.

Owner:YIBIN YATAI BIOTECH

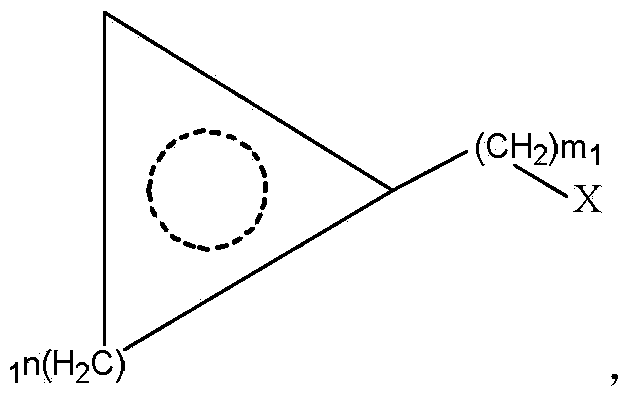

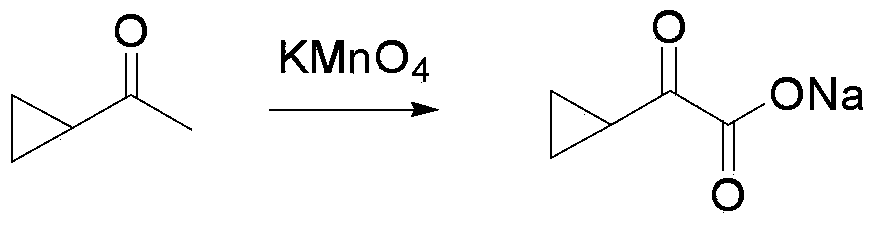

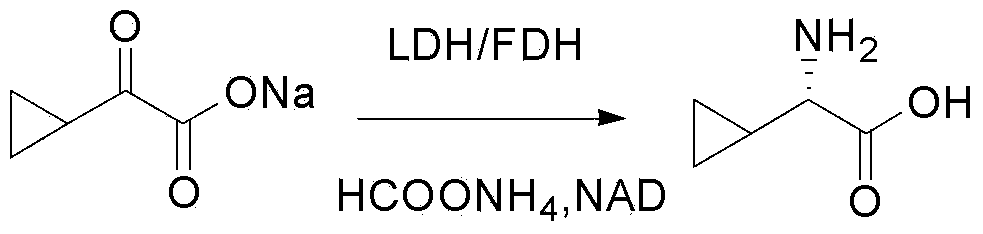

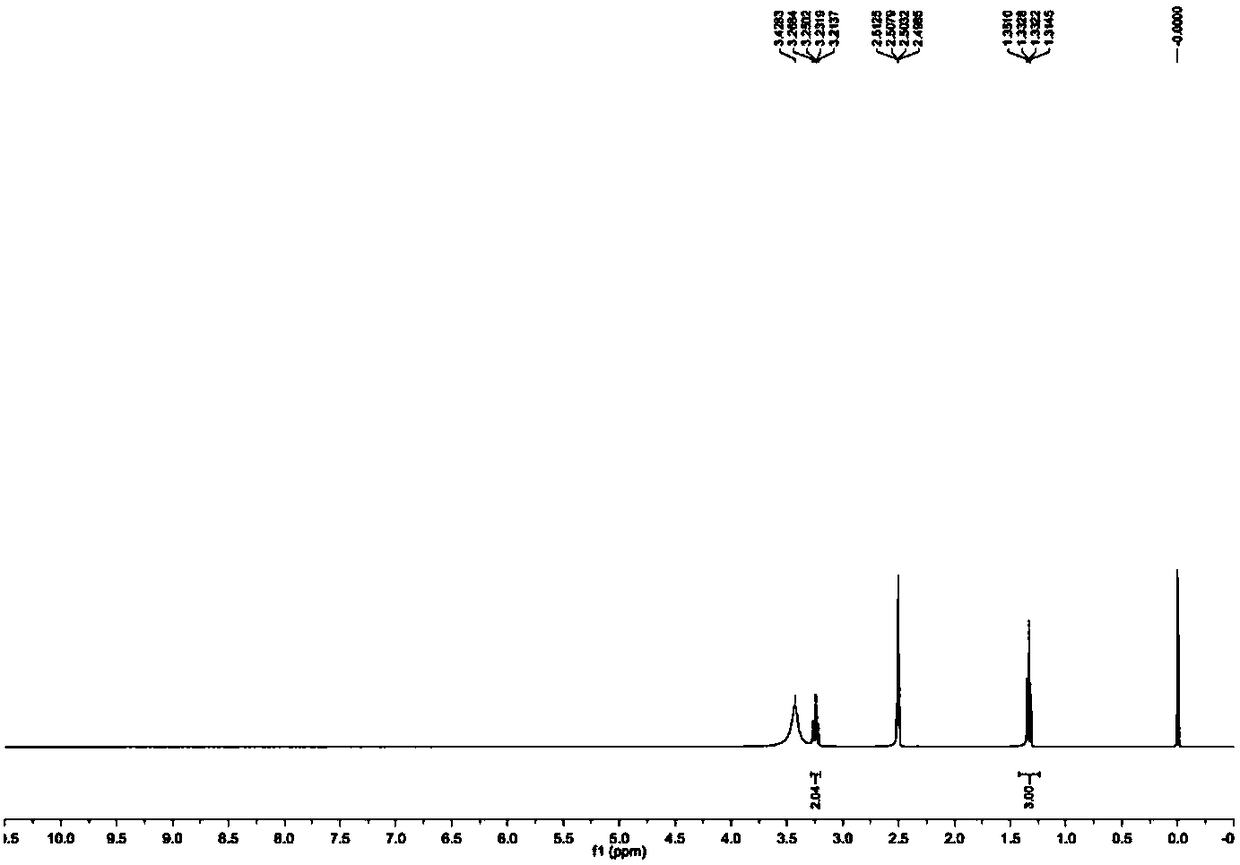

L-cyclic alkylamino acid synthesis method and medicinal composition containing L-cyclic alkylamino acid

ActiveCN103361388AHigh chiral selectivityRaw material conversion rate is highOrganic active ingredientsPeptide/protein ingredientsFormate dehydrogenaseLeucine dehydrogenase

The invention provides an L-cyclic alkylamino acid synthesis method and a medicinal composition containing L-cyclic alkylamino acid. The synthesis method comprises the following steps: 1, preparing cyclic alkyl ketonic acid or cyclic alkyl ketonate having a structure represented by formula (I) or formula (II); and 2, mixing the cyclic alkyl ketonic acid or cyclic alkyl ketonate with ammonium formate, a leucine dehydrogenase, a formate dehydrogenase and a coenzyme NAD<+>, and carrying out a reduction amination reaction to generate the L-cyclic alkylamino acid, wherein n1 in the formula (I) is not lower than 1, m1 in the formula is not lower than 0, and M1 is H or a univalent cation; n2 in the formula (II) is not lower than 0, m2 in the formula (II) is not lower than 0, and M2 is H or a univalent cation; and the amino acid sequence of the leucine dehydrogenase is represented by SEQ ID No.1. The method utilizes specific leucine dehydrogenase, the formate dehydrogenase and the coenzyme NAD<+> to carry out the reduction amination reaction of the cyclic alkyl ketonic acid or cyclic alkyl ketonate, and has a high raw material conversion rate and a high chiral selectivity.

Owner:ASYMCHEM LAB TIANJIN +4

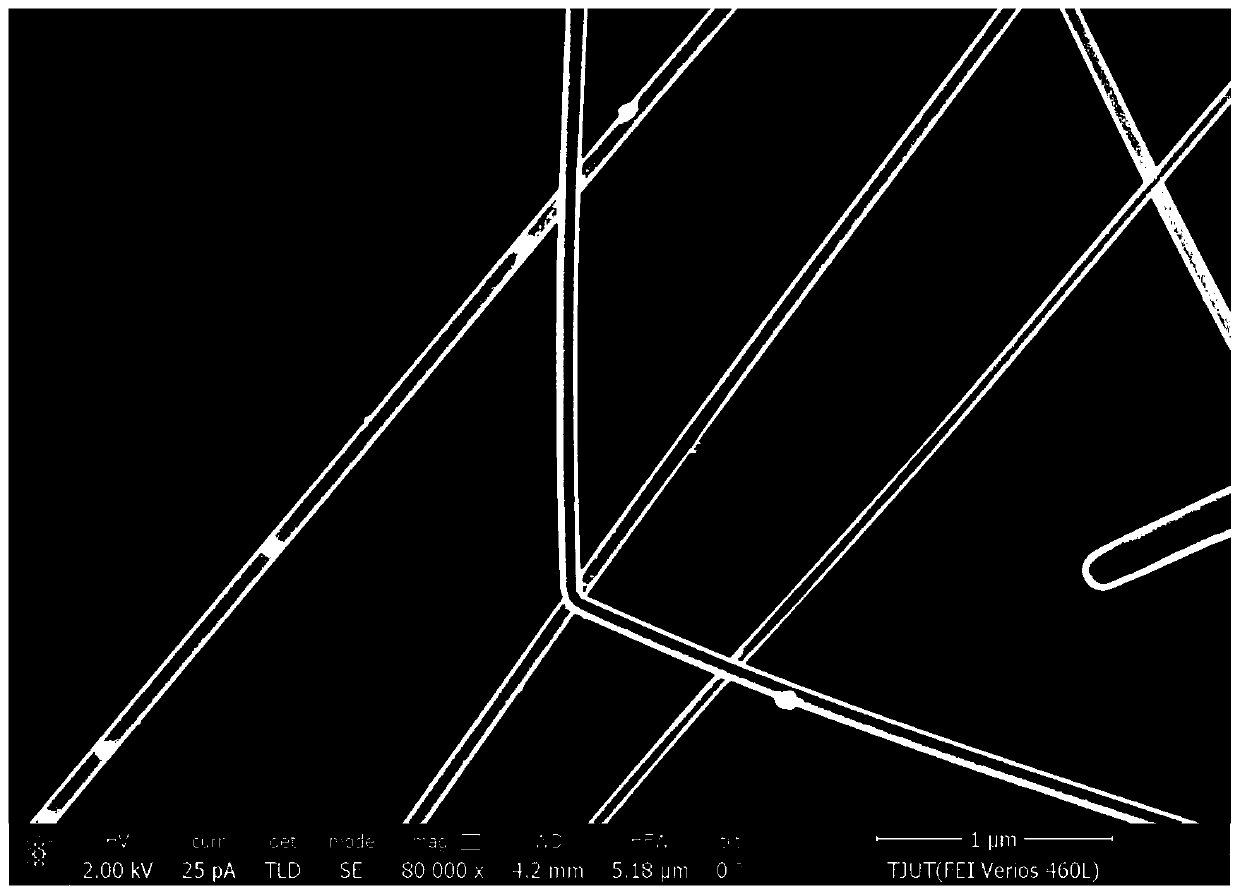

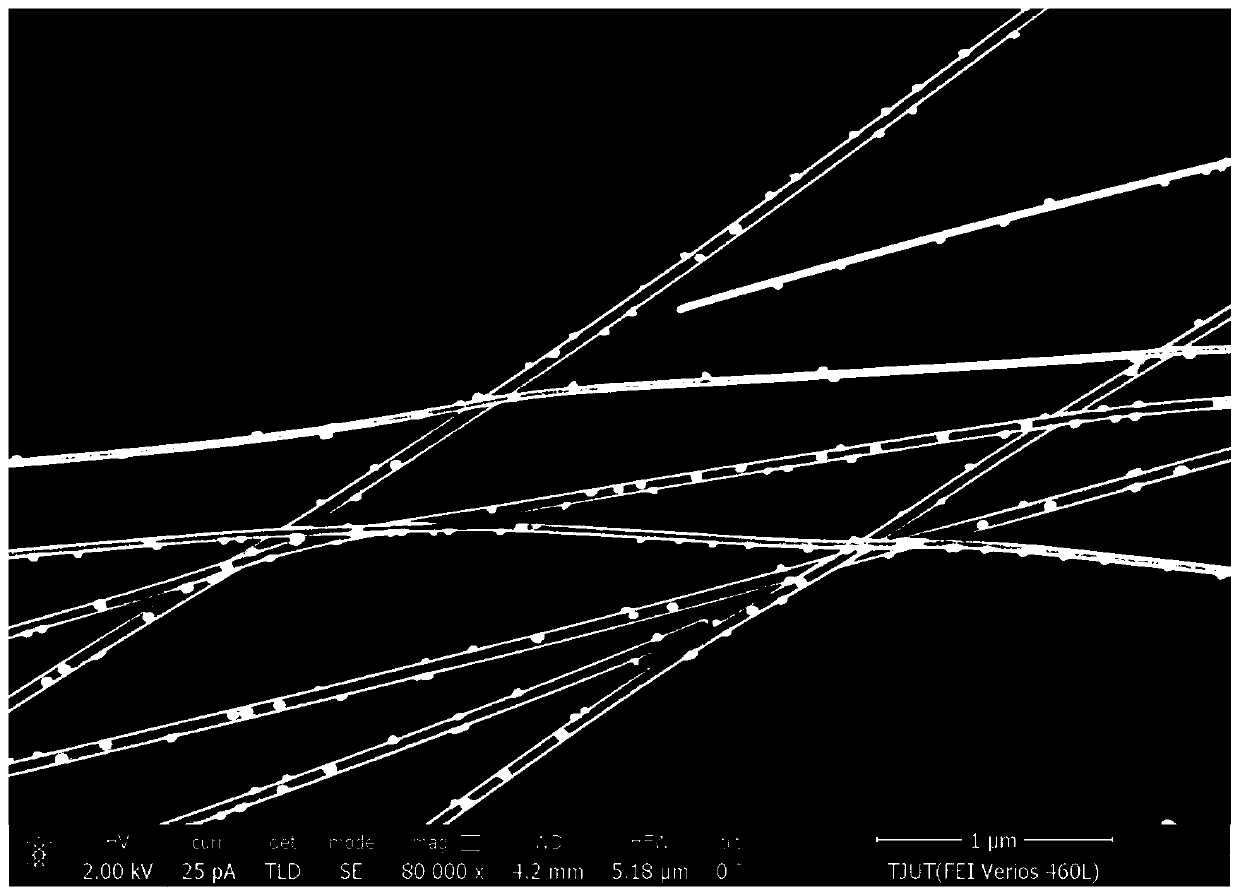

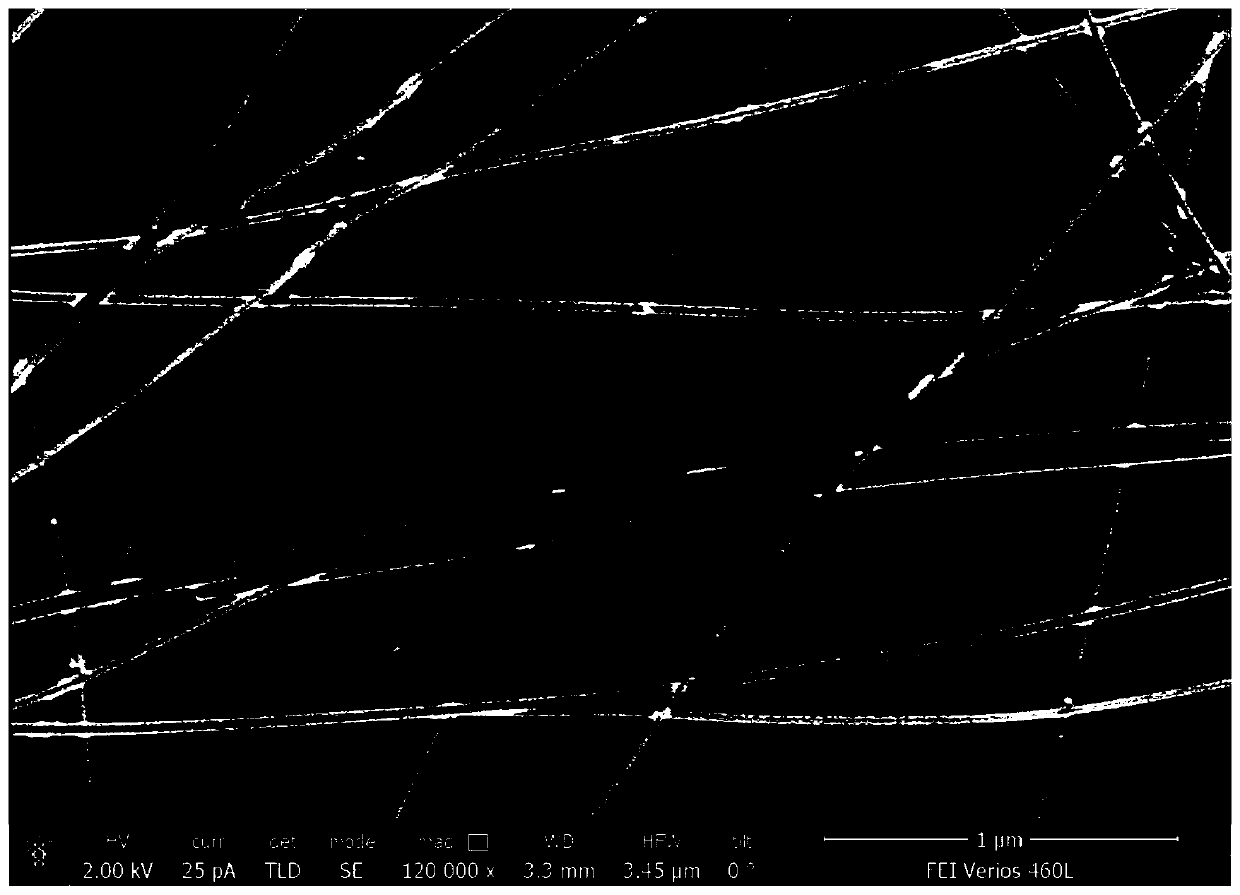

Nanometer silver wire as well as preparation method and application thereof

ActiveCN111001820AEasy to operateSimple manufacturing processMaterial nanotechnologyFinal product manufactureNanotechnology

The invention discloses a preparation method of a nanometer silver wire. A one-pot method is adopted, namely, the nucleation process and the growth process of the nanometer silver wire are sequentially carried out in the same reaction container. The theory of "low-temperature nucleation and high-temperature growth" is applied, that is, a nanometer-silver decahedron is formed at low temperature, and the growth of the nanometer silver wire is promoted at high temperature. The nanometer silver wire prepared by the method is uniform in diameter and size and has a large application prospect in thefields of electronic devices and / or photon devices.

Owner:宁波鑫智达新材料有限公司

Method for inhibiting fresh-cut yacon enzymatic browning

InactiveCN101647485ASimple processEasy to operateFruits/vegetable preservation by heatingFruits/vegetable preservation by freezing/coolingChemistryCitric acid

The invention discloses a method for inhibiting fresh-cut yacon enzymatic browning. In the method, a fresh-cut yacon is blanched at CaCl2 hot water solution at the temperature of 85-90 DEG C for 8-10minutes; after hot burning, the fresh-cut yacon is dipped into cold water to be cooled quickly; after being taken out, yacon sheets are put into a composite browning inhibitor solution which has the temperature of 20-25 DEG C and is composed of 0.10-0.13% of ascorbic acid, 0.07-0.09% of citric acid, 0.03-0.05% of cinnamic acid and 0.04-0.06% of ethylene diamine tetraacetic acid for 50-60 minutes.The invention can not bring the phenomena of pulp softening, after-ripening flavour and the like; the composite browning inhibitor has no sulphur, has safe and sanitary components, simple technology and convenient operation, can effectively prevent yacon sheets from changing into brown, has a favourable application effect and plays an important role in fine and further processing of yacon.

Owner:JISHOU UNIVERSITY

Electrodialysis process for preparing food-grade xylo-oligosaccharide from viscose fiber squeezed alkali liquor

InactiveCN104357513AAvoid damageLow running costSugar derivativesDisaccharidesFiltration membraneIon exchange

The invention provides an electrodialysis process for preparing food-grade xylo-oligosaccharide from viscose fiber squeezed alkali liquor. The process comprises the following specific process steps: (A) carrying out membrane concentration: firstly pre-filtering squeezed liquor for viscose fiber production, so as to remove large-granule impurities, cyclically concentrating the permeate for 2-4 times with a nano-filtration membrane, feeding the finally-concentrated concentrate to an electrodialysis membrane reactor, and recovering alkali liquor, namely a concentrate of the squeezed liquor, from an anode chamber, wherein during the 2-4 times of cyclic concentrating of the nano-filtration membrane, before every filtration, material liquid is thinned up with water and then enters the nano-filtration membrane; (B) extracting hemicellulose: adding acid to neutralize the concentrate of the squeezed alkali liquor, so as to obtain hemicellulose liquid; (C) carrying out enzymolysis: adding a compound enzyme into the hemicellulose liquid, and carrying out enzymolysis reaction, so as to obtain an enzymolysis solution; (D) purifying: filtrating the enzymolysis solution with the ceramic membrane, desalting the permeate with the nano-filtration membrane, enabling the obtained concentrate to be subjected to activated charcoal decoloring and resin ion exchange, so as to obtain a purified solution of xylo-oligosaccharide, evaporating and baking, thereby obtaining the food-grade xylo-oligosaccharide.

Owner:YIBIN YATAI BIOTECH

Method for preparing food-grade xylo-oligosaccharide from viscose fiber squeezed alkali solution

InactiveCN104404104AAvoid damageHigh process efficiencySemi-permeable membranesFermentationEnzymatic hydrolysisHydrolysate

The invention provides a method for preparing food-grade xylo-oligosaccharide from a viscose fiber squeezed alkali solution. The technology comprises the following steps: step A, membrane condensation: pre-filtering the squeezed alkali solution, which is generated during the production process of viscose fibers, to remove the large particle impurities, adding water into the filtrate to dilute the filtrate, then processing the diluted filtrate by a primary nano-filter membrane so as to obtain primary concentrate, adding water to dilute the primary concentrate, then processing the diluted primary concentrate by a secondary nano-filter membrane so as to obtain the secondary concentrate, diluting the secondary concentrate by water, then processing the diluted secondary concentrate by a ceramic membrane so as to obtain the concentrate namely the concentrate of squeezed alkali solution; step B, semi-fiber extraction: adding acid into the obtained concentrate to neutralize the alkali solution so as to obtain a semi-fiber solution; step C, enzymatic hydrolysis: adding composite enzymes into the semi-fiber solution to carry out enzymatic hydrolysis so as to obtain enzymatic hydrolysate; step D, purification: filtering the enzymatic hydrolysate by a ceramic membrane, then filtering the filtrate by a nano-filter membrane to remove the salts, decoloring the obtained concentrate by active carbon, then making the concentrate go through a resin column to carry out ion exchange so as to obtain a purified xylo-oligosaccharide solution, and finally evaporating and drying the solution so as to obtain food-grade xylo-oligosaccharide.

Owner:YIBIN GRACE GROUP CO LTD

Process for producing feed-grade xylo-oligosaccharide from viscose fiber squeezed alkali liquor

InactiveCN104357591AAvoid damageImprove filtration efficiencyXylose productionFiltration membraneCeramic membrane

The invention provides a process for producing feed-grade xylo-oligosaccharide from viscose fiber squeezed alkali liquor. The process comprises the following specific process steps: (A) carrying out membrane concentration: firstly pre-filtering squeezed liquor for viscose fiber production, so as to remove large-granule impurities, cyclically concentrating the permeate for 2-4 times with a nano-filtration membrane, thinning up the finally-concentrated concentrate with water, and filtrating with a ceramic membrane, so as to obtain a concentrate, namely a concentrate of the squeezed alkali liquor, wherein during the 2-4 times of cyclic concentrating of the nano-filtration membrane, before every filtration, material liquid is thinned up with water and then enters the nano-filtration membrane; (B) extracting hemicellulose: adding acid to neutralize the concentrate of the squeezed alkali liquor, so as to obtain hemicellulose liquid; (C) carrying out enzymolysis: adding a compound enzyme into the hemicellulose liquid, and carrying out enzymolysis reaction, so as to obtain an enzymolysis solution; (D) purifying: filtrating the enzymolysis solution with the ceramic membrane, desalting the permeate with the nano-filtration membrane, so as to obtain a concentrate, namely a purified solution of xylo-oligosaccharide, evaporating and baking, thereby obtaining the feed-grade xylo-oligosaccharide.

Owner:YIBIN GRACE GROUP CO LTD

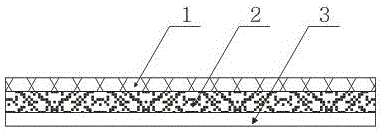

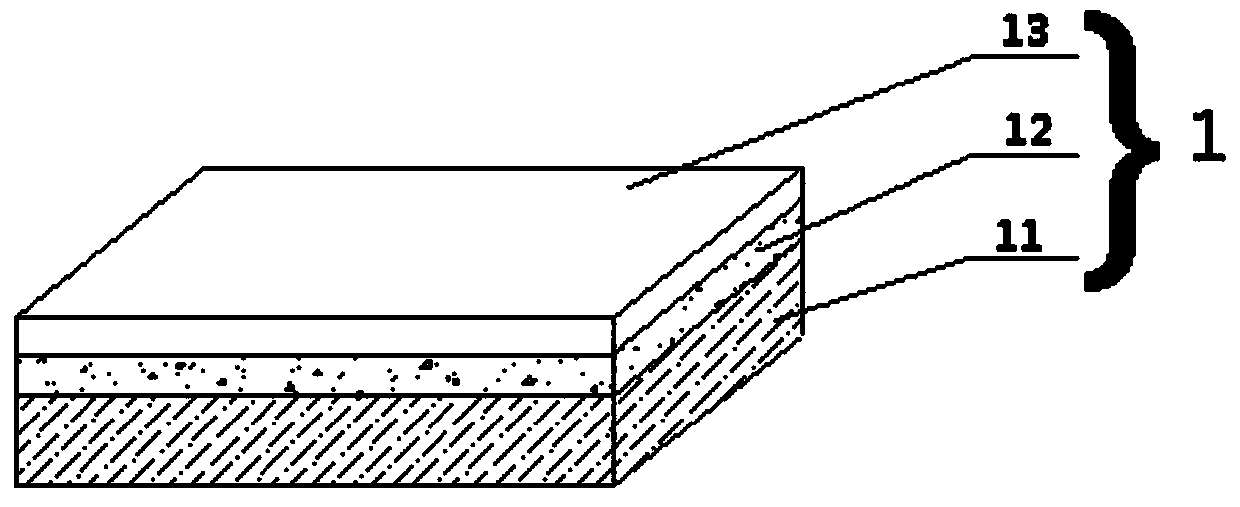

Medical silicone gel tape and preparation method thereof

InactiveCN106726140ASmall structureSimple production processNon-adhesive dressingsAdhesive dressingsSilicone GelsPolymer science

The invention discloses a medical silicone gel tape and preparation method thereof, which relates to the technology field of materials or devices of a bandage, a dressing, an absorbent pad or and a surgical article. The medical silicone gel tape comprises a nonwoven fabric layer, a silicone gel layer and a release type substrate. The nonwoven fabric layer, the silicone gel layer and the release substrate are arranged in order from top to bottom. The silicone gel layer is formed on the nonwoven fabric layer by a silicone gel semi-solid state. The medical silicone gel tape and preparation method thereof is applied to medical clinical dressing, and has the advantages of good air permeability, good fit and the like.

Owner:ZHENDE MEDICAL CO LTD

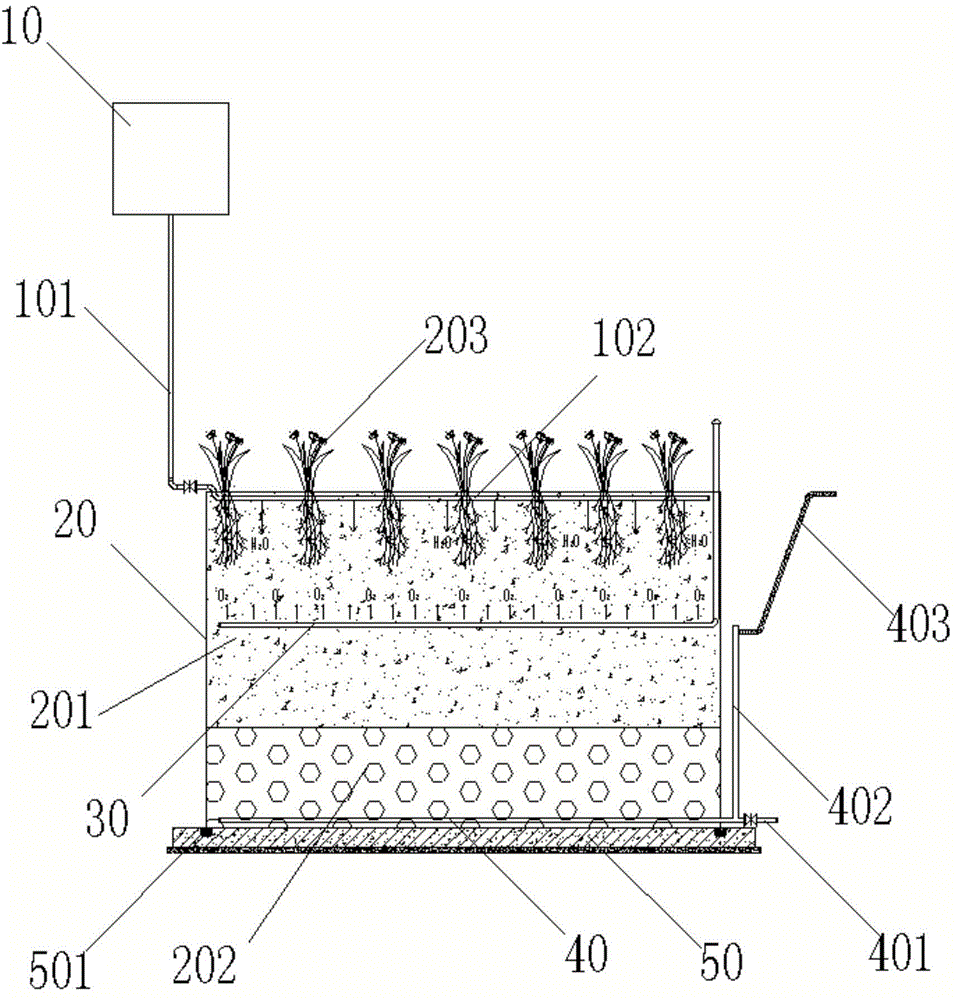

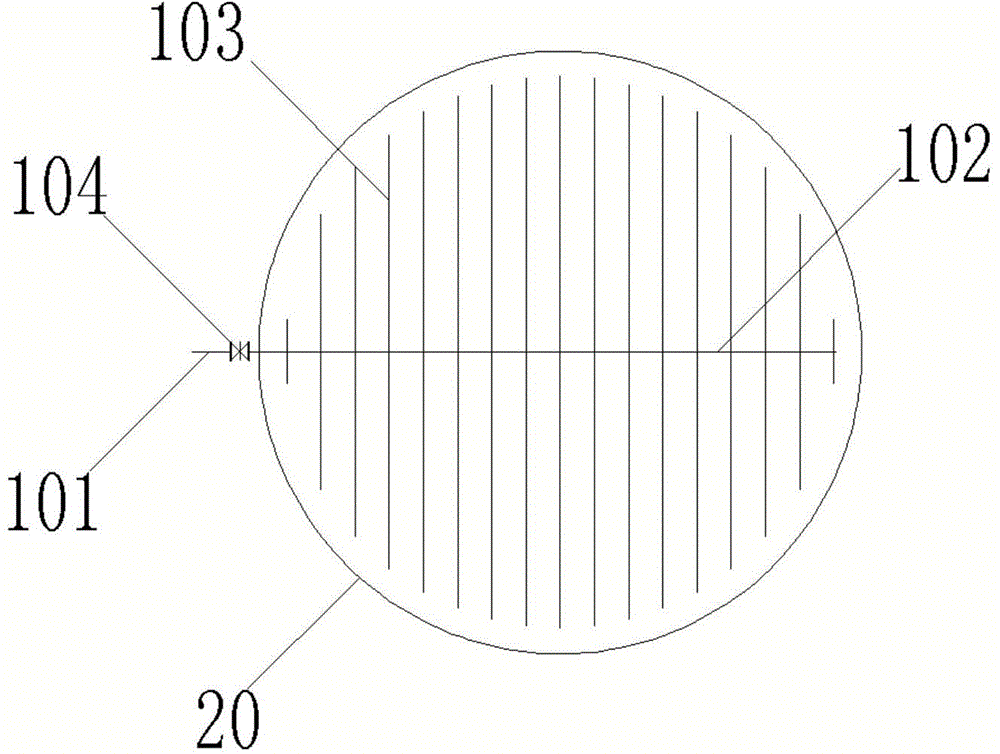

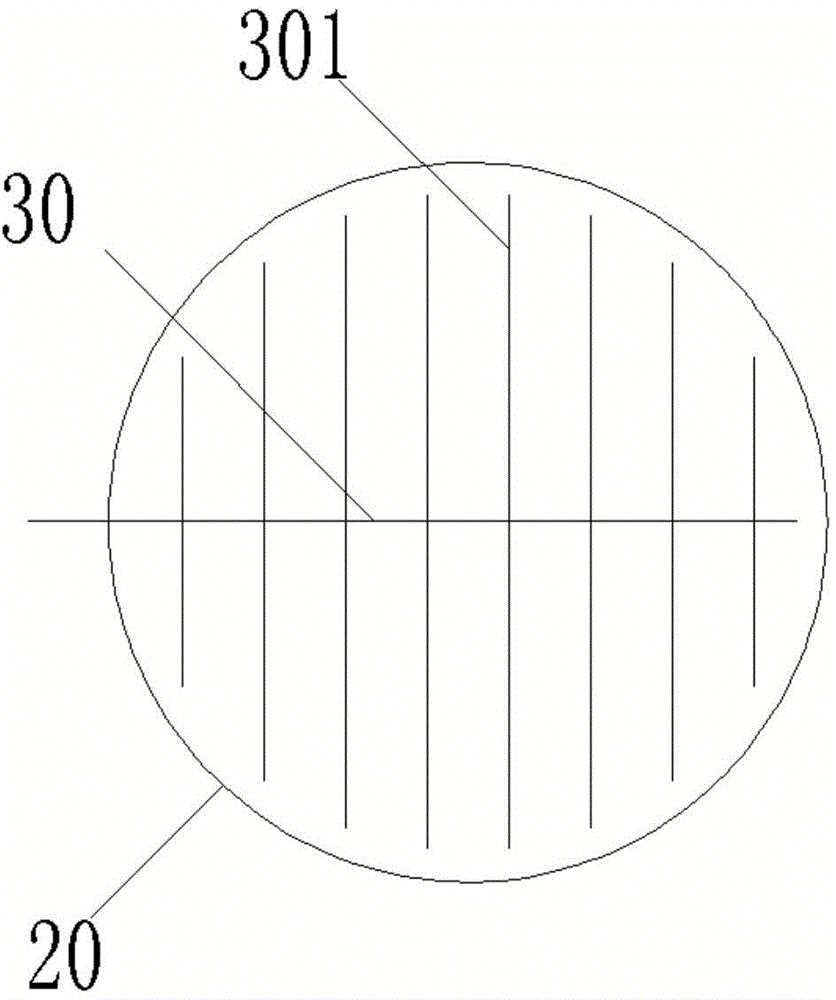

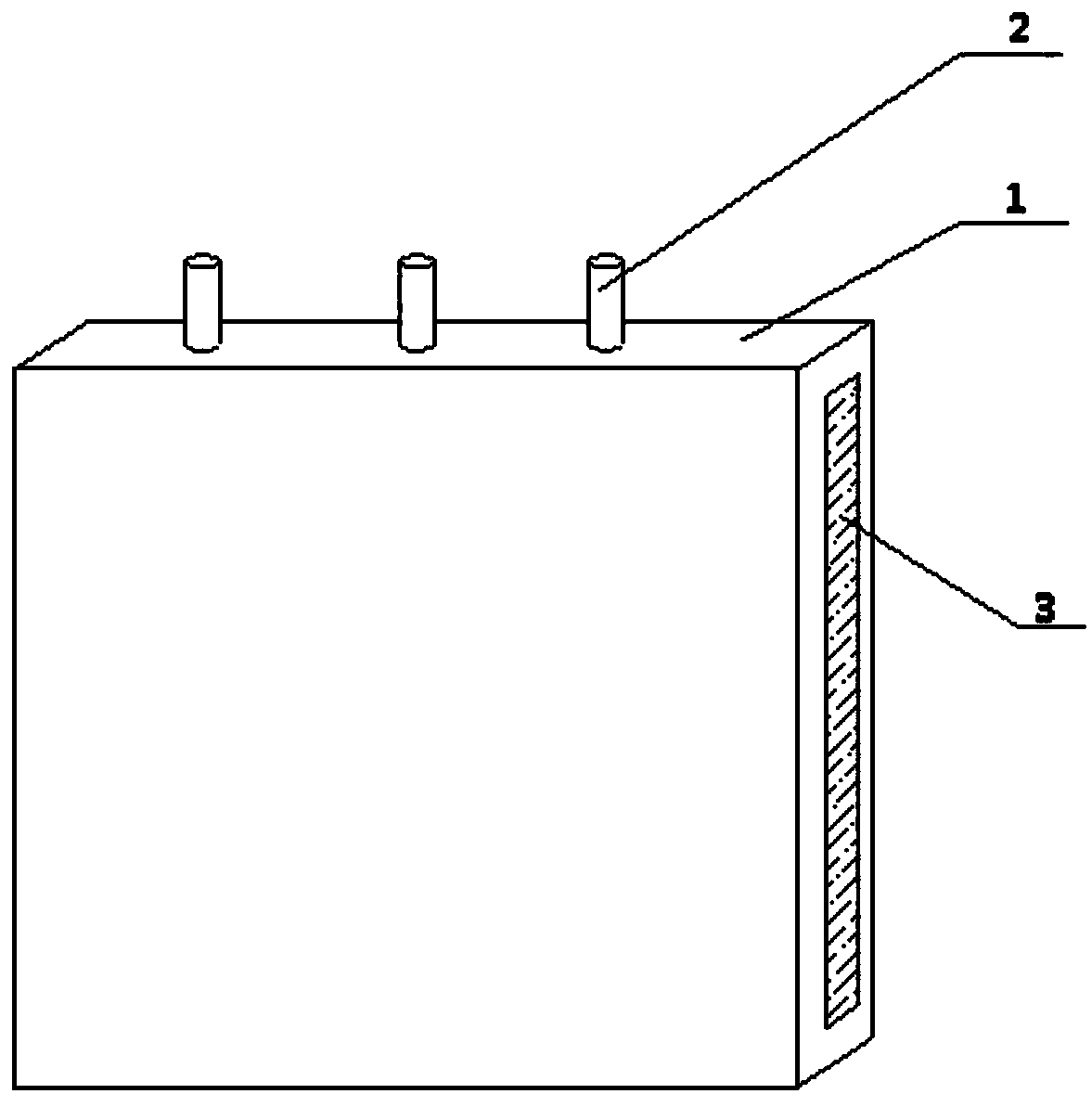

Detachable variable-water-level vertical-current artificial wetland

ActiveCN104163496ASimple structureEasy to install and useSustainable biological treatmentBiological water/sewage treatmentPipingTreatment effect

The invention relates to a detachable variable-water-level vertical-current artificial wetland which comprises a high water level tank (10), a wetland tank (20), an air pipe (30), a water collection pipe (40) and a base (50), wherein the bottom of the high water level tank (10) is connected with a water inlet pipe (101); the water inlet pipe (101) is connected with a surface water distribution pipeline of the wetland tank (20); the tank wall is spliced by PVC (polyvinyl chloride) boards; the air pipe (30) is arranged at the middle part of the wetland tank (20); the top end of the air pipe (30) is communicated with air; the water collection pipe (40) is positioned on the bottom of the wetland tank (20); one end of the water collection pipe (40) is connected with a water outlet pipe (402); and the top end of the water outlet pipe (402) is connected with a rotary bent pipe (403). By adopting the detachable mode for splicing and construction, the artificial wetland has the advantages of simple structure and favorable treatment effect, is convenient to install, can reutilize the land, and effectively achieves the goals of material reutilization and waste reduction.

Owner:HANGZHOU WENYUAN ENERGY SAVING ENVIRONMENTAL PROTECTION TECH +1

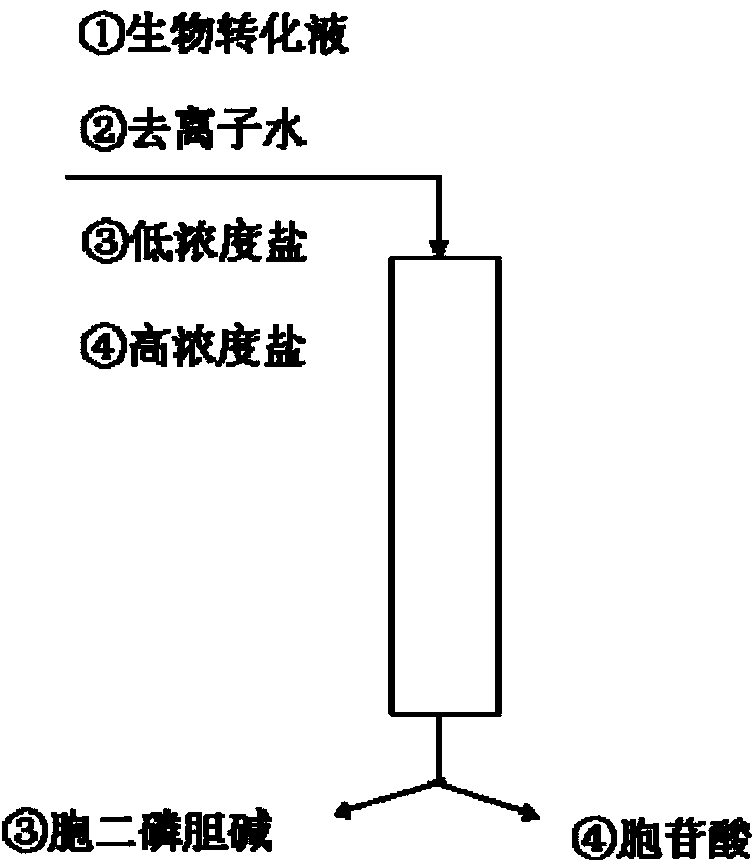

Method for separating and purifying citicoline in issatchenkia orientalis biotransformation liquid

ActiveCN103819522ALow costHigh yieldSugar derivativesSugar derivatives preparationIon-exchange resinDrug biotransformation

The invention discloses a method for separating and purifying citicoline in an issatchenkia orientalis biotransformation liquid. The method comprises the following steps: the issatchenkia orientalis CDP-c biotransformation liquid is passed through an anion exchange resin column, deionized water is used for leaching an unadsorbed substance, a salt solution of 0.01-0.50M is employed for eluting CDP-C and the salting liquid of 0.10-1.00M is employed for eluting cytidylic acid, so that CDP-c with high purity (greater than 99%) and high yield (greater than 88%) can be obtained by one time, and the cytidylic acid without complete reaction can be recovered. The method for separating and purifying citicoline in the issatchenkia orientalis biotransformation liquid greatly simplify a separating process, the operation is simple, the cost is low, and the environment is protected, and is adapted to large-scale industrial production.

Owner:无锡泰仑达化机设备有限公司

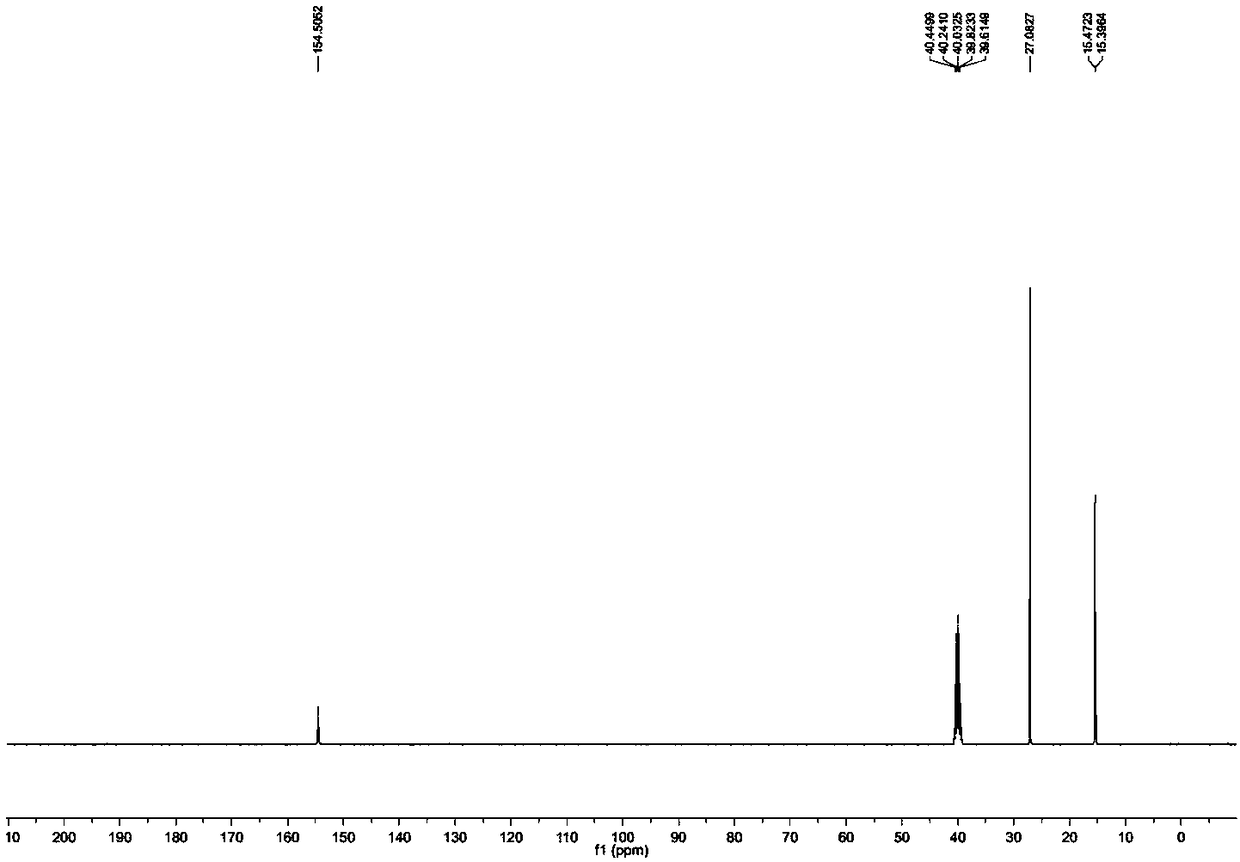

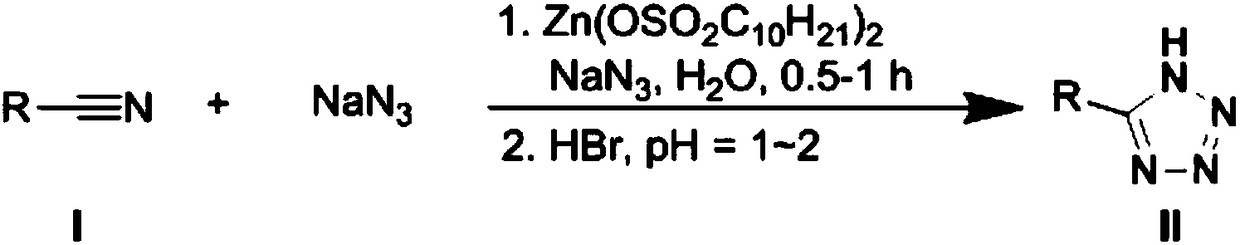

Method for catalytically preparing 5'-substituted tetrazole compound by zinc Lewis acid surfactant

InactiveCN108358863AHigh catalytic efficiencyImprove stabilityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsZinc bromideTetrazole

The invention belongs to the technical field of organic synthesis and in particular relates to a method for preparing a 5'-substituted tetrazole compound by taking a zinc Lewis acid surfactant as a catalyst. The method comprises the following steps: 1) taking the zinc Lewis acid surfactant Zn(OSO2CnH2n+1)2 as the catalyst and enabling R group nitrile and sodium azide to react in water, so as to obtain zinc salt of a 5'-R group tetrazole compound and a byproduct NaOSO2CnH2n+1; 2) acidifying the zinc salt of the 5'-R group tetrazole compound obtained by step 1) under an acidic condition to obtain the 5'-R group tetrazole compound and a byproduct zinc bromide; 3) carrying out substitution reaction on the byproduct NaOSO2CnH2n+1 and the byproduct zinc bromide under an acidic condition to obtain the zinc Lewis acid surfactant Zn(OSO2CnH2n+1)2. In the method, a one-pot-method strategy can be adopted and starting raw materials are subjected to continuous cyclization reaction and acidification reaction to directly prepare a target compound containing a tetrazole structure unit; the zinc Lewis acid surfactant used in the method can be recycled after the reaction is finished.

Owner:湖北佰智昂生物化工有限公司

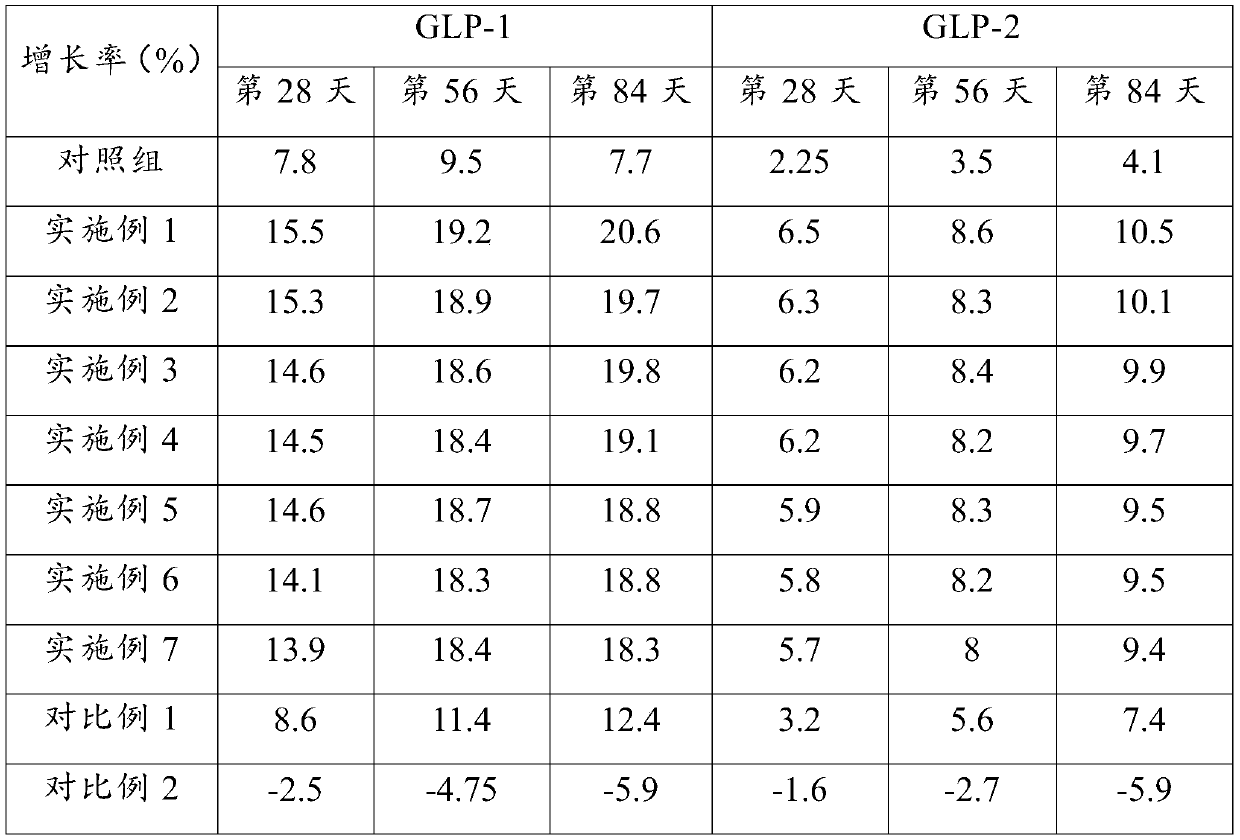

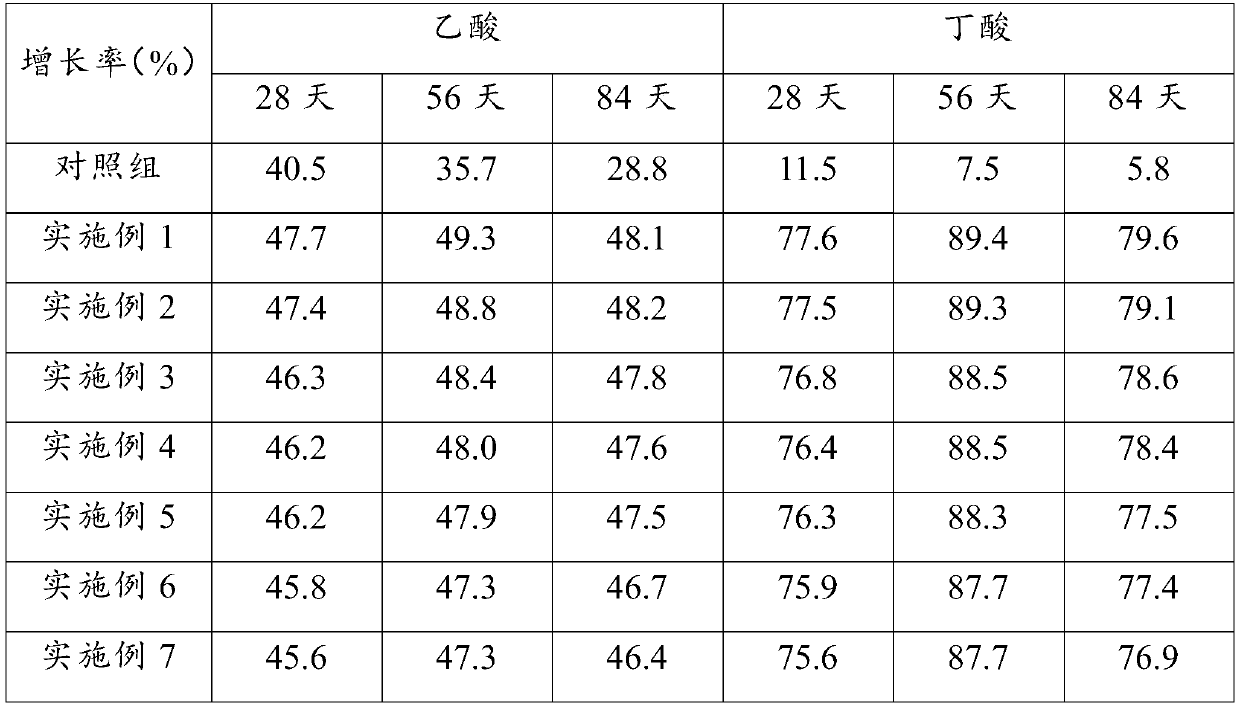

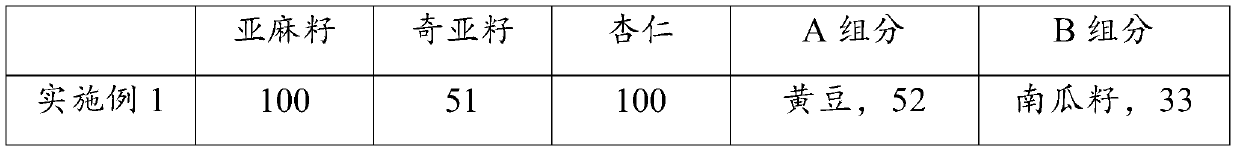

Nutritional dietary compositions and edible product

The invention relates to the field of food, in particular to a nutritional dietary composition and an edible product containing the nutritional dietary composition. The nutritional dietary compositioncomprises flaxseeds, chia seeds, a component A and a component B, wherein the component A is soybeans and / or red beans; the component B is one plant seed or a mixture of multiple plant seeds, a content weight ratio of total dietary fibers to total proteins in the component B is (0.8-1): 1, the content of the total proteins in the component B is 8-25 wt%, and the content of total carbon and waterin the component B is 20-75 wt%; and relative to 100 parts by weight of the flaxseeds, the content of the chia seeds is 40-70 parts by weight, the content of the component A is 40-65 parts by weight,and the content of the component B is 20-45 parts by weight. The product disclosed by the invention can effectively regulate blood sugar, has the advantages of good taste, no side effect, capability of being eaten as meal replacement, and the like.

Owner:深圳市瑞辰健康管理有限公司

Membrane concentration process for preparing food-grade xylo-oligosaccharide from squeezed liquor for viscose fiber production

InactiveCN104357590AAvoid damageImprove filtration efficiencyXylose productionFiltration membraneIon exchange

The invention provides a membrane concentration process for preparing food-grade xylo-oligosaccharide from squeezed liquor for viscose fiber production. The process comprises the following specific process steps: (A) carrying out membrane concentration: firstly pre-filtering squeezed liquor for viscose fiber production, so as to remove large-granule impurities, cyclically concentrating the permeate for 2-4 times with a nano-filtration membrane, thinning up the finally-concentrated concentrate with water, and filtrating with a ceramic membrane, so as to obtain a concentrate, namely a concentrate of squeezed alkali liquor, wherein during the 2-4 times of cyclic concentrating of the nano-filtration membrane, before every filtration, material liquid is thinned up with water and then enters the nano-filtration membrane; (B) extracting hemicellulose: adding acid to neutralize the concentrate of the squeezed alkali liquor, so as to obtain hemicellulose liquid; (C) carrying out enzymolysis: adding a compound enzyme into the hemicellulose liquid, and carrying out enzymolysis reaction, so as to obtain an enzymolysis solution; (D) purifying: filtrating the enzymolysis solution with the ceramic membrane, desalting the permeate with the nano-filtration membrane, enabling the obtained concentrate to be subjected to activated charcoal decoloring and resin ion exchange, so as to obtain a purified solution of xylo-oligosaccharide, evaporating and baking, thereby obtaining the food-grade xylo-oligosaccharide.

Owner:YIBIN GRACE GROUP CO LTD

Membrane concentration process for preparing xylitol from viscose production pressed liquor

InactiveCN104357492AAvoid damageImprove filtration efficiencySemi-permeable membranesMicroorganism based processesEnzymatic hydrolysisHydrolysate

The invention provides a membrane concentration process for pressing xylitol from viscose pressed liquor. The membrane concentration process comprises the following specific process steps: A, performing membrane concentration, wherein the viscose production pressed liquor is firstly prefiltered to remove large-particle impurities, penetrated liquor is circularly concentrated 2-4 times by virtue of a nanofiltration membrane, concentrated liquor obtained at the last time is diluted by being added with water and then fed into a ceramic membrane for being filtered, and the obtained concentrated liquor is the concentrated pressed alkali liquor; the feed liquor is diluted by being added with water and then enters the nanofiltration membrane before the penetrated liquor is filtered when the penetrated liquor is circularly condensed 2-4 times by virtue of the nanofiltration membrane; B, extracting hemicellulose to neutralize the concentrated pressed alkali liquor by adding acid to obtain hemicellulose liquid; C, performing enzymolysis, wherein compound enzyme is added into the hemicellulose liquid to generate enzymatic hydrolysis to obtain enzymatic hydrolysate; D, fermenting, wherein the enzymatic hydrolysate is fermented for 0.5-2 hours at 50-60 DEG C under the action of candida mycoderma bacteria; and E, purifying, wherein the fermented liquor is ultra-filtered to remove impurities, and the penetrated liquor is desalinized by virtue of the nanofiltration membrane, the obtained concentrated liquor is purified liquor of xylitol, and the xylitol is obtained by virtue of ion exchange, active carbon treatment, concentration and crystallization and separation.

Owner:YIBIN GRACE GROUP CO LTD

Raw tea processing method capable of completely eliminating raw dark green tea bitterness

InactiveCN110432341AEliminate bitternessSolve want to solvePre-extraction tea treatmentHigh volume manufacturingGreen tea

The invention discloses a raw tea processing method capable of completely eliminating raw dark green tea bitterness, and relates to a tea processing method, in particular to a processing method of rawdark green tea. The processing method includes the steps of tea standing, killing out, rolling, pile fermentation and drying, the special feature of the processing method is that secondary killing out is carried out after the rolling step, and secondary rolling is carried out after the secondary killing out. According to the raw tea processing method capable of completely eliminating the raw darkgreen tea bitterness, unexpected technical effects are achieved, the raw dark green tea bitterness is completely eliminated, the problem that people want to solve for a long time but still is not solved is solved, the process is simple, and the processing method is not restricted by human operation skills, and can adapt to industrial mass production.

Owner:安化山春堂茶业有限公司

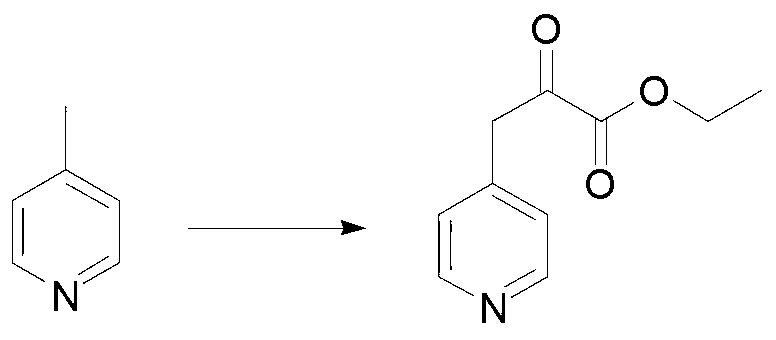

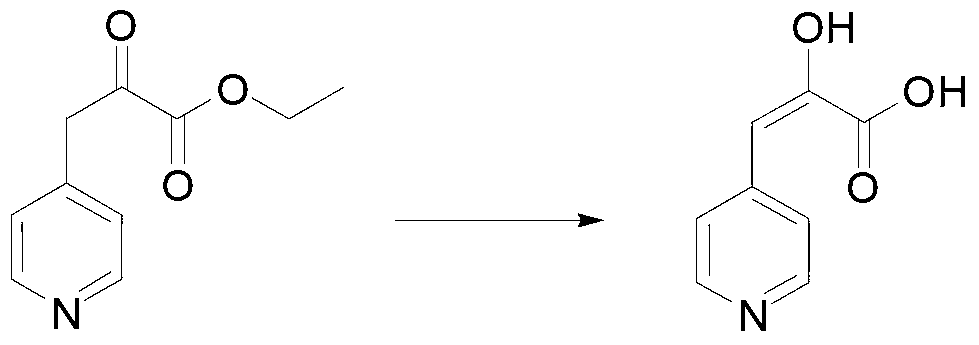

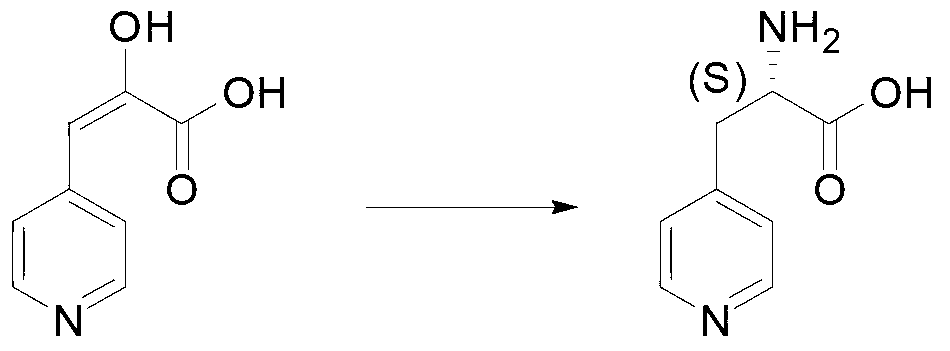

Synthetic method of L-heterocyclic amino acid and pharmaceutical composition with L-heterocyclic amino acid

ActiveCN103276025AThe synthesis process is simpleAdapt to industrial mass productionOrganic active ingredientsFermentationAlkyl transferPhenylalanine dehydrogenase

The invention provides a synthetic method of L-heterocyclic amino acid and a pharmaceutical composition with L-heterocyclic amino acid. The synthetic method comprises the steps that A, heterocyclic ketonic acid is prepared, wherein heterocycle in heterocyclic ketonic acid is selected from any one of pentabasic single heterocycle, hexabasic single heterocycle, heptabasic single heterocycle, pentabasic alkylation single heterocycle, hexabasic alkylation single heterocycle and heptabasic alkylation single heterocycle, and a structural formula of ketonic acid base in heterocyclic ketonic acid is as shown in the specification, and is positioned in any carbon position of heterocycle; and B, heterocyclic ketonic acid is mixed with ammonium formate, phenylalanine dehydrogenase, formate dehydrogenase and coenzyme NAD<+> to perform a reduced amination reaction to generate L-heterocyclic amino acid, wherein an amino acid sequence of phenylalanine dehydrogenase is SEQ ID No. 1 (sequence identifier number 1). Since special phenylalanine dehydrogenase, formate dehydrogenase and coenzyme NAD<+> are used for allowing heterocyclic ketonic acid to perform the reduced amination reaction to generate L-heterocyclic amino acid, the raw material conversion rate is high and the chiral selectivity is high.

Owner:ASYMCHEM LAB TIANJIN +4

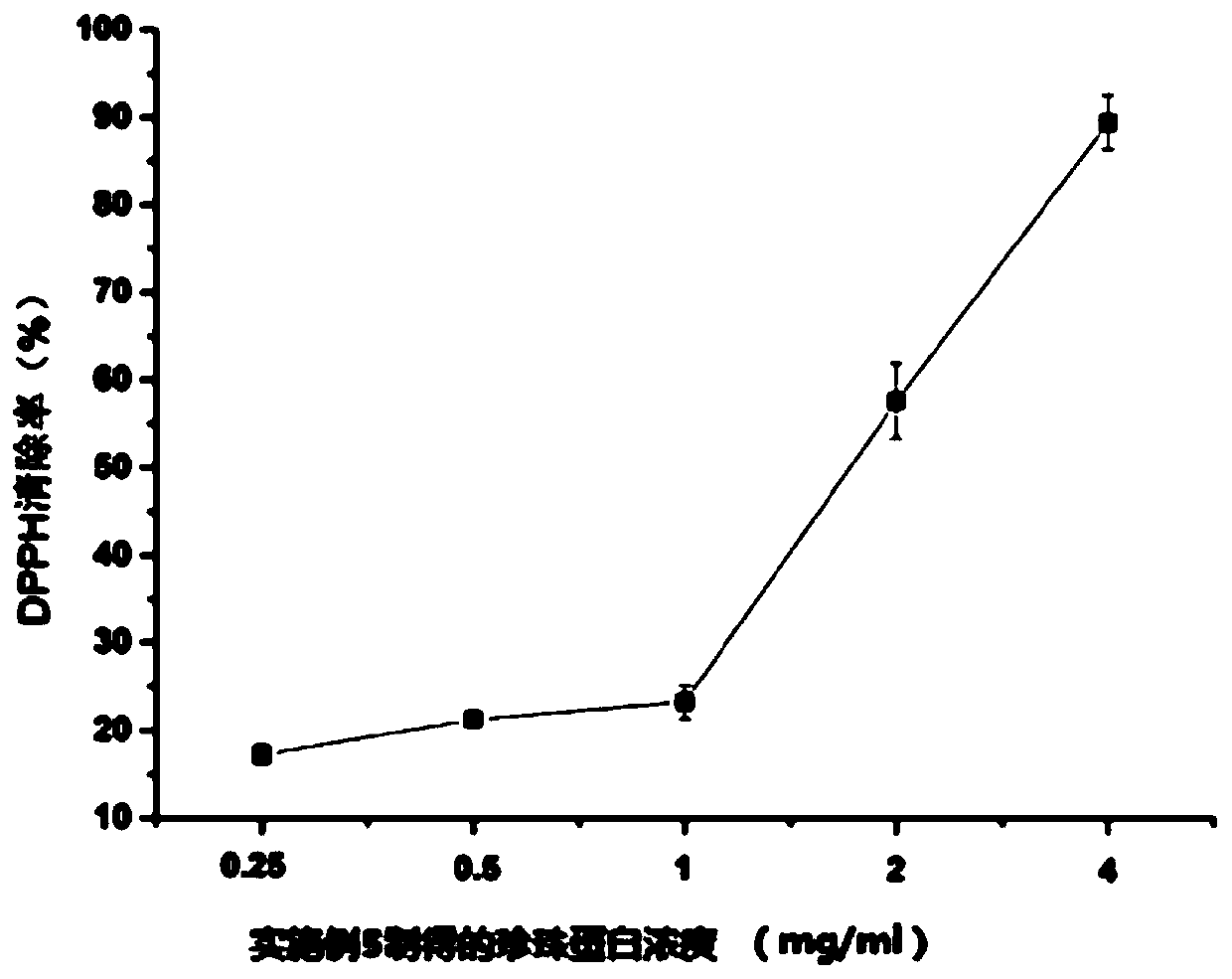

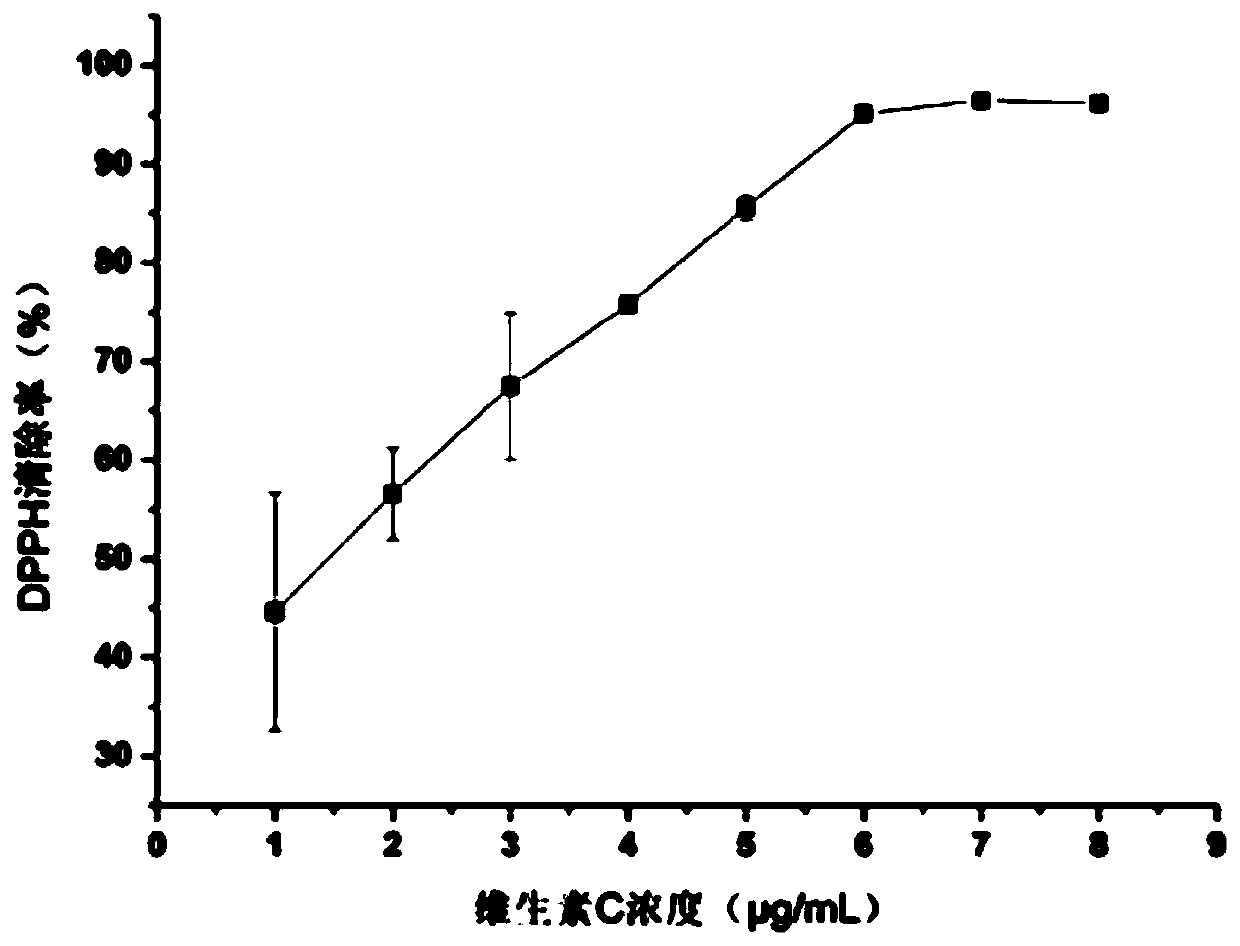

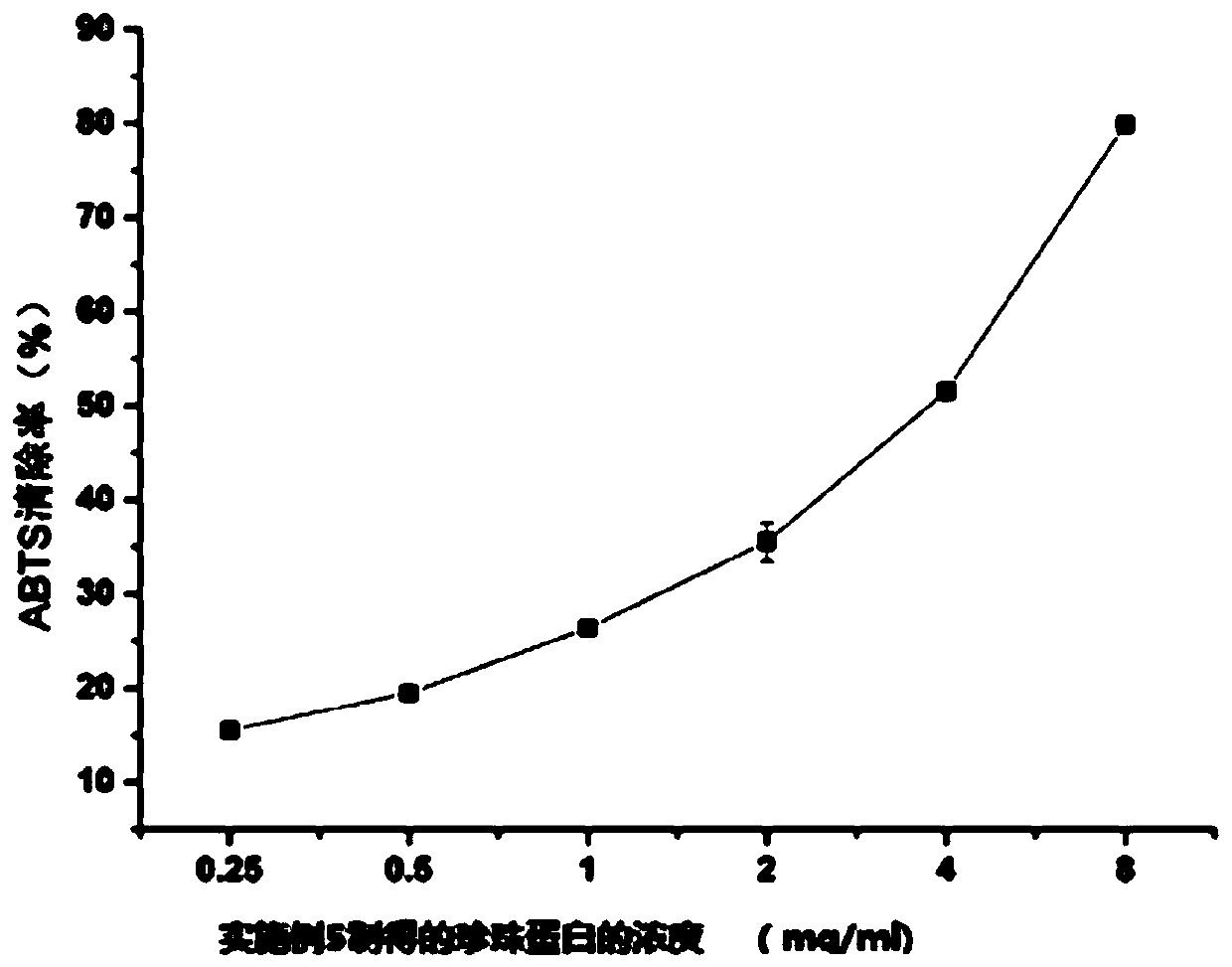

Pearl protein and preparation method and application thereof, and cosmetic containing pearl protein

PendingCN111455010AGood for skin absorptionGood permeabilityCosmetic preparationsToilet preparationsProteaseMolecular biology

The invention provides a pearl protein and a preparation method and application thereof, and a cosmetic containing the pearl protein, and relates to the technical field of deep processing of pearl products. The preparation method comprises the following steps: (a), providing an aqueous suspension containing a pearl powder, and then hydrolyzing the aqueous suspension under the action of protease toobtain a hydrolyzed solution A; (b), hydrolyzing the hydrolyzed solution A obtained in the step (a) under the action of lactic acid to obtain a hydrolyzed solution B; and (c), sequentially performingsolid-liquid separation and desalination treatment on the hydrolyzed solution B obtained in the step (b) to obtain the pearl protein. The preparation method uses the protease and lactic acid to sequentially hydrolyze the aqueous suspension containing the pearl powder to prepare the pearl protein, and the pearl protein prepared by the preparation method is more easily absorbed by the skin. At thesame time, the preparation method of the invention does not have the problem of organic solvent residue after the hydrolyzed solution B is treated by the filtering and desalting method, and thereby isvery suitable for industrialized large-scale production.

Owner:GUANGDONG MARUBI BIOLOGICAL TECH CO LTD

Process for producing food-grade xylo-oligosaccharide from viscose fiber squeezed alkali liquor

InactiveCN104357516AAvoid damageImprove filtration efficiencySugar derivativesDisaccharidesActivated carbonFood grade

The invention provides a process for producing food-grade xylo-oligosaccharide from viscose fiber squeezed alkali liquor. The process comprises the following specific process steps: (A) carrying out membrane concentration: firstly pre-filtering squeezed liquor for viscose fiber production, so as to remove large-granule impurities, cyclically concentrating the permeate for 2-4 times with a nano-filtration membrane, thinning up the finally-concentrated concentrate with water, and filtrating with a ceramic membrane, so as to obtain a concentrate, namely a concentrate of the squeezed alkali liquor, wherein during the 2-4 times of cyclic concentrating of the nano-filtration membrane, before every filtration, material liquid is thinned up with water and then enters the nano-filtration membrane; (B) extracting hemicellulose: adding acid to neutralize the concentrate of the squeezed alkali liquor, so as to obtain hemicellulose liquid; (C) carrying out enzymolysis: adding a compound enzyme into the hemicellulose liquid, and carrying out enzymolysis reaction, so as to obtain an enzymolysis solution; (D) purifying: filtrating the enzymolysis solution with the ceramic membrane, desalting the permeate with the nano-filtration membrane, enabling the obtained concentrate to be subjected to activated charcoal decoloring and resin ion exchange, so as to obtain a purified solution of xylo-oligosaccharide, evaporating and baking, thereby obtaining the food-grade xylo-oligosaccharide.

Owner:YIBIN GRACE GROUP CO LTD

Fish noodle and production method thereof

The invention relates to a fish noodle comprising major ingredients and minor ingredients, the major ingredients include fish 800-1000 parts, starch 300-500 parts, water 300-500 parts, the minor ingredients include the following raw materials (by weight ratio of the major ingredients): 0.3-0.5% of crisp enhancer, 0.1-0.3% of flavoring agent, 0.1-0.3% of gourmet powder, 2-3% of table salt, 1-3% of white sugar, 3-5% of lard, 2-4% of fresh ginger, 0.1-0.3% of pepper powder, 1-3% of egg white. The process for preparing the noodle consists of preliminary treatment, collecting meat, cooling down through refrigeration, making fish glue, mixing, stirring, forming, shaping, cooling down and packaging.

Owner:卢建中

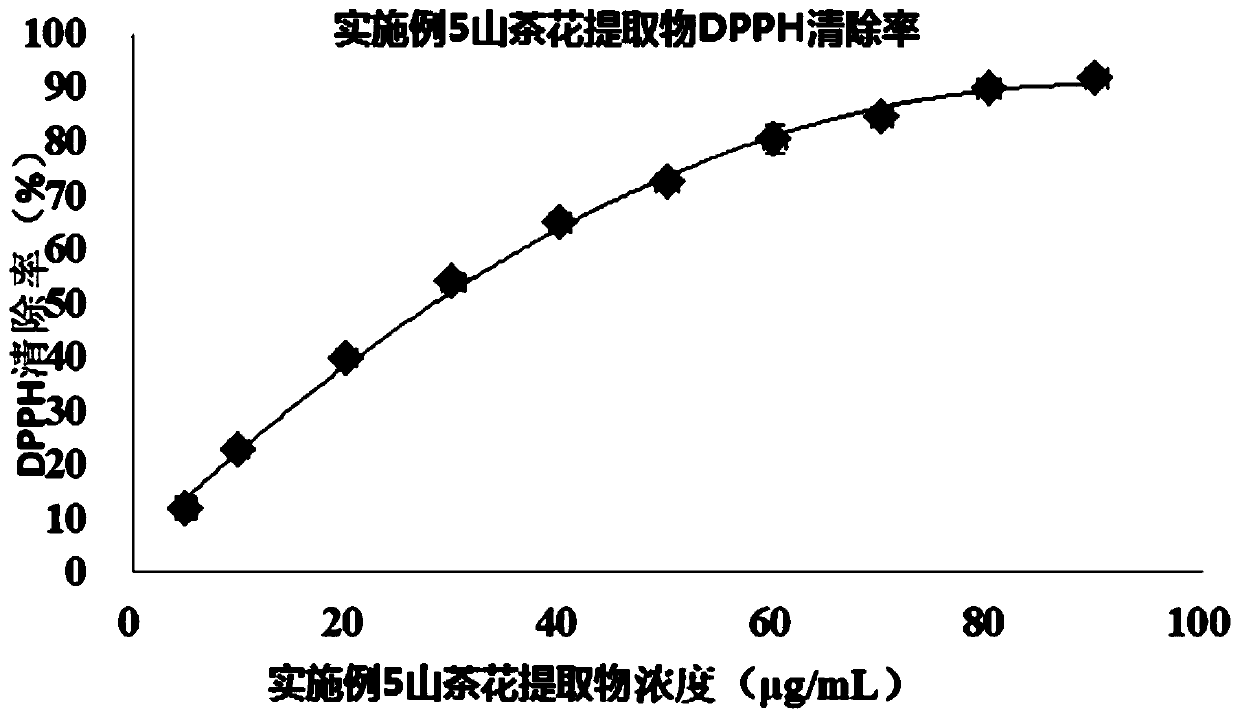

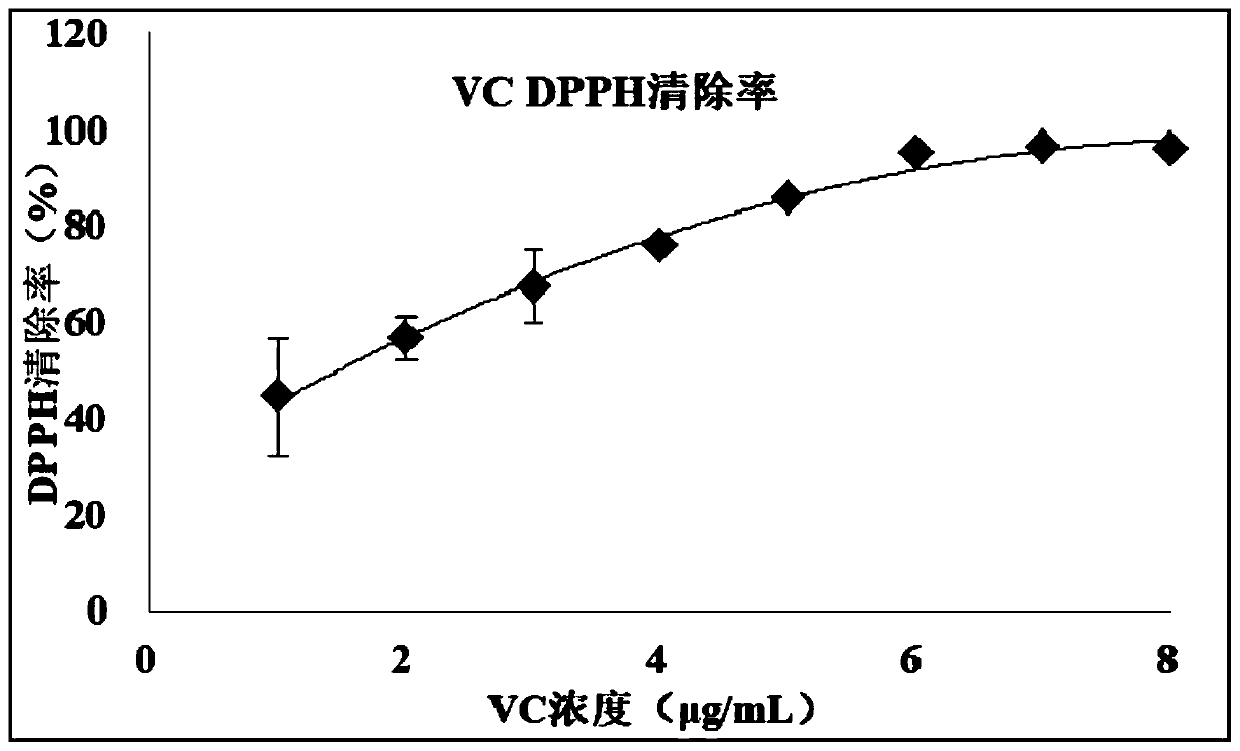

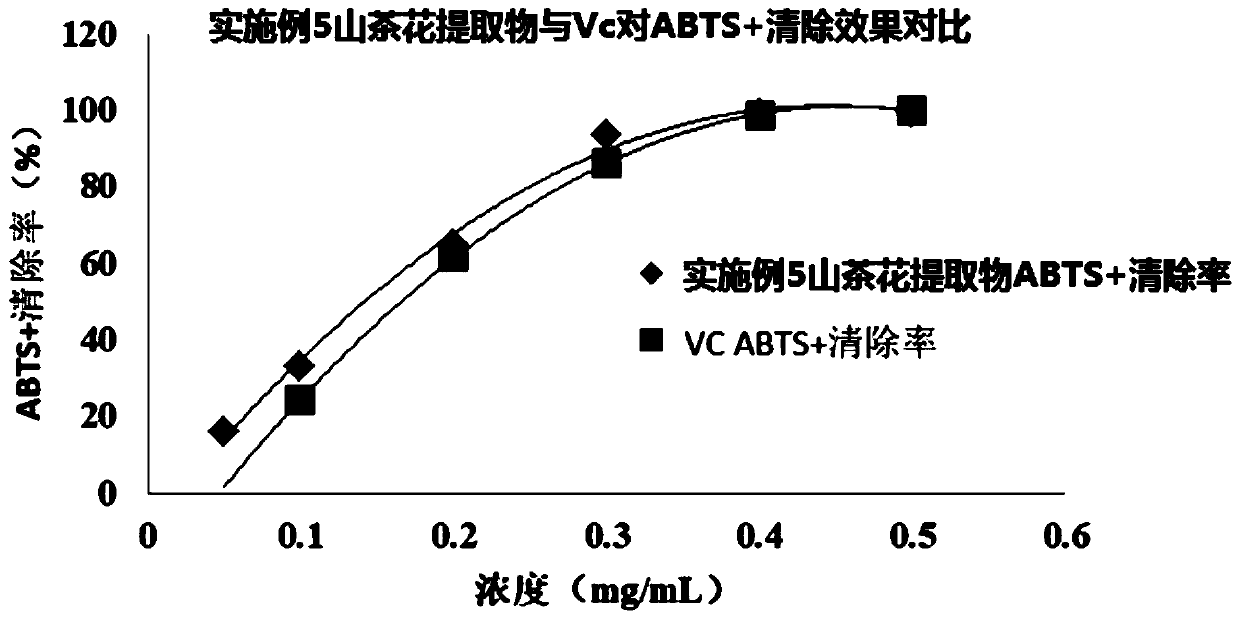

Camellia extract as well as preparation method and application thereof, and cosmetic containing camellia extract

PendingCN111407699AGood for skin absorptionStrong antioxidant activityCosmetic preparationsToilet preparationsAmmonium sulfateCamellia japonica flower extract

The invention provides a camellia extract as well as a preparation method and an application thereof, and a cosmetic containing the camellia extract, and relates to the technical field of deep processing of camellia products. The preparation method comprises the following steps of firstly, performing ultrasonic extraction on camellia, and then performing a reaction between an extracting solution and a metal ion complexing agent to obtain a precipitate A; and sequentially carrying out decreaming and extraction on the precipitate A to obtain a camellia extract, wherein the ultrasonic extractionsolvent comprises ethanol and ammonium sulfate. The camellia extract extracted by the preparation method has the advantages of high extraction rate and strong antioxidant activity; and meanwhile, thepreparation method is mild in condition and easy to operate, and is very suitable for industrial large-scale production.

Owner:GUANGDONG MARUBI BIOLOGICAL TECH CO LTD

Method for reducing aldehyde content of melamine impregnating solution in papermaking industry under premise of guaranteeing quality and output

InactiveCN108914663AReduce the binding forceImprove bindingNon-macromolecular adhesive additivesCalendersEpoxyFiber

The invention discloses a method for reducing the aldehyde content of melamine impregnating solution in the papermaking industry under the premise of guaranteeing quality and output. The method adoptsparts by weight to prepare 200 to 220 parts of pine wood material, 15 to 20 parts of porcelain clay, 8 to 10 parts of silicon dioxide powder, 40 to 43 parts of epoxy chloropropane, 14 to 15 parts ofadipic acid, 12.5 to 13 parts of melamine, 25 to 30 parts of peach juvenile branchlet, 2 to 3 parts of aqueous cellulase solution, 2 to 3 parts of silicate bacterium agent, 5 to 8 parts of white-rot fungus agent, enough acetic acid and enough hydrogen peroxide as materials, and the process comprises six steps: preparation of raw materials, preparation of wood fibers, rupture of cell walls, preparation of binder, preliminary shaping and dry sterilization and paper shaping. The invention has the advantages of no formaldehyde, easy manufacturing process implementation, continuous manufacturing, intact fibers, environment-friendliness, no public hazard, high fiber yield, suitability for industrial mass production and stable quality.

Owner:临沂市鲁源浸渍纸业有限公司

Membrane concentration process of extracting hemicellulose from pressed liquid produced by viscose fiber production

The invention provides a membrane concentration process of extracting hemicellulose from pressed liquid produced by viscose fiber production. The membrane concentration process is characterized by comprising the following steps: prefiltering the pressed liquid produced by the viscose fiber production firstly to remove large-particle impurities, concentrating permeated liquid by a nanofiltration membrane for 2-4 times in a circulation mode, conveying a concentrated liquid obtained at the last time into a ceramic membrane to be filtered after being diluted by adding water, and neutralizing the obtained concentrated liquid by adding acid to obtain hemicellulose liquid. According to the membrane concentration process provided by the invention, the nanofiltration membrane is used for concentration for 2-4 times in the circulation mode; before filtration for each time, feed liquid enters the nanofiltration membrane after being diluted by water; the obtained hemicellulose liquid is low in alkali concentration, low in salinity, high in hemicellulose purity, high in process running efficiency and applied to large-scale production.

Owner:YIBIN GRACE GROUP CO LTD

Membrane Concentration Process for Production of Xylitol Using Viscose Fiber Press Liquid as Raw Material

ActiveCN104311391BAvoid damageImprove filtration efficiencySugar derivativesOrganic compound preparationHydrolysisLarge particle

The invention provides a membrane concentration technology for producing xylitol by using viscose fiber pressed liquor as raw materials. The technology comprises the following specific steps: A, membrane concentration: the pressed liquor produced by viscose fibers is firstly processed in a pre-filter manner to remove impurities with large particles to enter a micro-filter membrane to be processed, the penetrated liquor is concentrated two to four times in a circulating manner through a nano filter film, the final concentrated liquor is diluted by adding the water to be sent into a ceramic membrane to be filtered, and the obtained concentrated liquor is the concentrated liquor of the pressed alkali liquor; the nano filter membrane is concentrated two to four times in a circulating manner, and before filtration each time, the material liquor is diluted by adding the water to enter the nano filter film; B, semi fiber extraction: the acid is added into the concentrated liquor of the pressed alkali liquor to neutralize to obtain semi fiber liquor; C, hydrolysis: dilute sulphuric acids are added into the semi fiber liquor to carry out the hydrolysis; D, purification: the hydrolysis liquor is filtered through the ceramic membrane, the penetrated liquor enters the nano filter membrane to be desalted, and the concentrated liquor is decolored through active carbon to obtain the purified liquor; E, hydrogenation: the hydrogen is communicated into the purified liquor of xylose, and the hydrogenation is carried out on the basis of the catalysis of nickel to obtain the xylitol.

Owner:YIBIN GRACE GROUP CO LTD

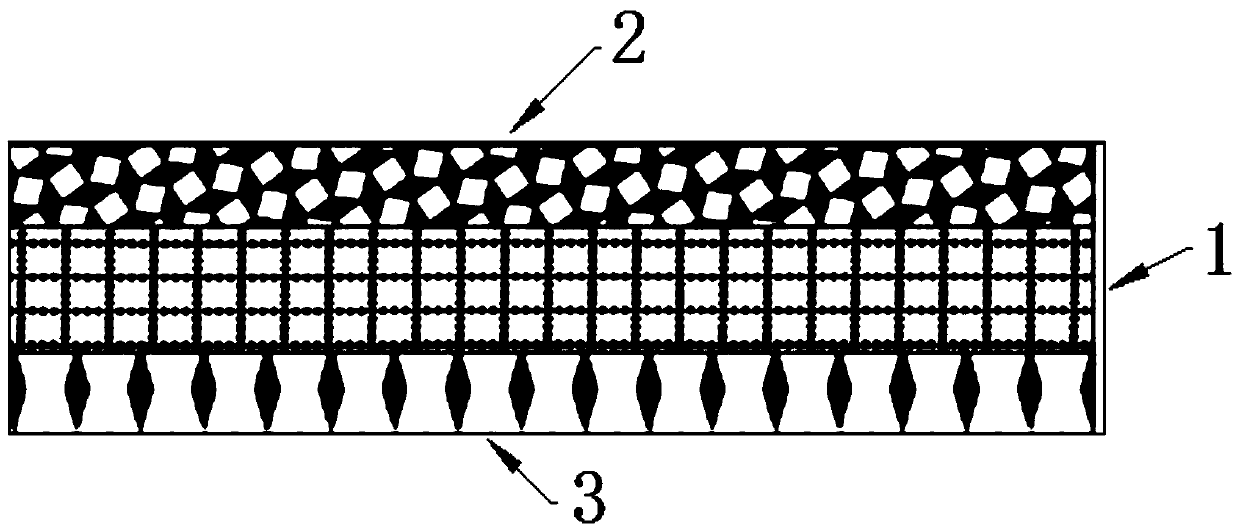

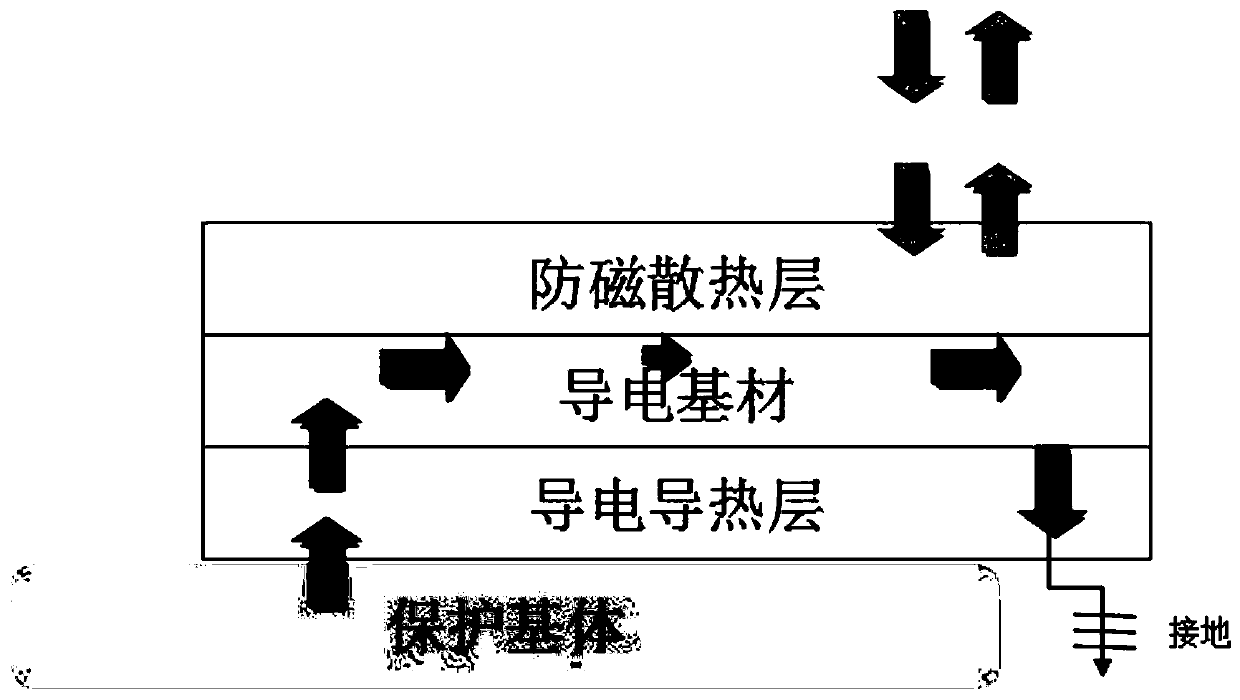

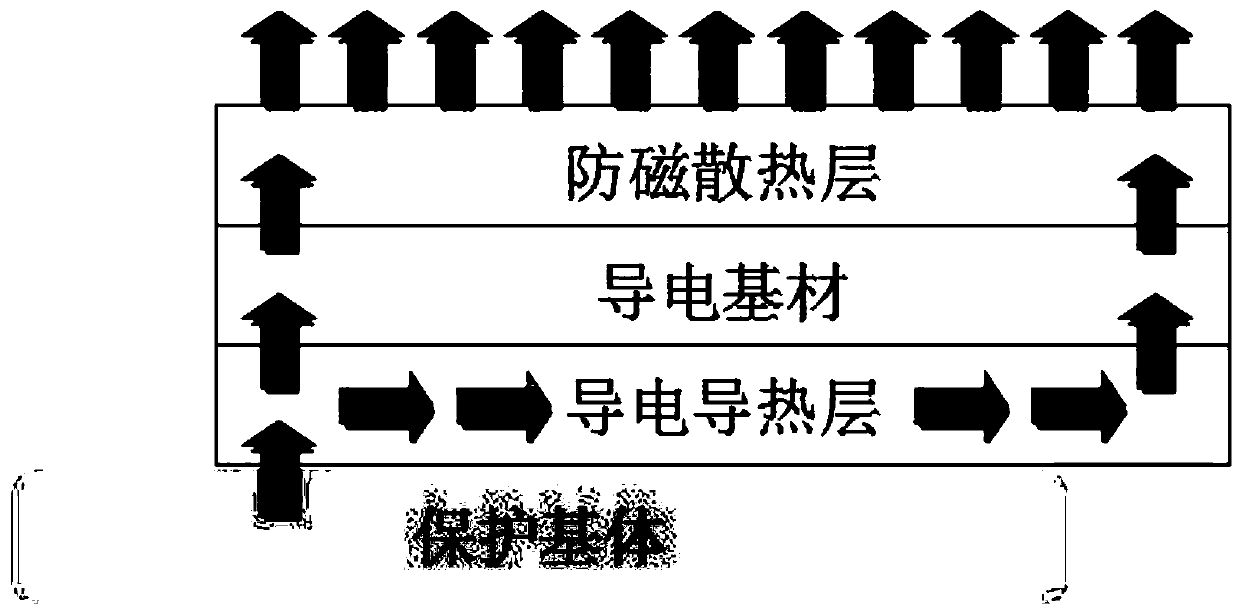

High-frequency protection single-sided glue preparation method

InactiveCN110437756ASimple and fast operationAdapt to industrial mass productionNon-macromolecular adhesive additivesPressure sensitive film/foil adhesivesHeat conductingElectromagnetic interference

The invention discloses a high-frequency protection single-sided glue preparation method, which comprises that one surface of a metal substrate layer is compounded with an anti-magnetic heat dissipation layer, and the other surface of the metal substrate is compounded with a piercing type heat conducting layer. According to the present invention, one surface provides electric conduction shieldingfunction, and the other surface provides magnetic field absorption shielding function, such that the whole functions are heat conduction and heat dissipation; and the product solves the problems of high electromagnetic interference and high heat generation caused by strong signal transmission in a high frequency process.

Owner:广东亚龙兴新材料有限公司

Inner plate wall for building intelligent installation project and preparation method thereof

PendingCN109094063AGood fixed limit effectThere are no potential safety hazardsWallsSynthetic resin layered productsArchitectural engineeringSlurry

The invention relates to the technical field of building inner plate walls and preparation thereof, in particular to an inner plate wall for a building intelligent installation project and a preparation method thereof. The inner plate wall for the building intelligent installation project includes a wall body, a vertical fixing column, a magnetic plate and a metal plate, the wall body is successively provided with a reinforcing layer, a color-changing coating and a waterproof layer, reinforcing ribs are installed inside the reinforcing layer, and the injection molding material of the reinforcing layer is silicon-aluminum composite material. The preparation method includes the following steps that the silicon-aluminum composite material is injected into a mold of the reinforcing layer for injection molding, calendaring molding is carried out on photosensitive color-changing raw materials, slurry of the waterproof layer is sprayed on the surface of the color-changing coating by ultrasonic vibration to form the waterproof layer, and the magnetic plate, the metal plate and the vertical fixing column are installed in a groove of the wall body. The inner plate wall for the building intelligent installation project and the preparation method thereof has the advantages of good sound insulation effect, good bearing effect, easy installation and small potential safety hazard.

Owner:JIANGSU DAMEITIANDI CULTURE IND CO LTD

Dietary fiber composition and edible product

PendingCN111406940AGreat tasteImprove physical functionFood ingredient functionsBiotechnologyMeal replacement

The invention relates to the field of food, and specifically relates to a dietary fiber composition and an edible product containing the dietary fiber composition. The dietary fiber composition includes flaxseed, chia seeds, almonds, an A component and a B component; the A component is soybeans and / or red beans; the B component is a kind of plant seeds or the mixing of various plant seeds, the content-weight ratio of total dietary fiber to total protein is (0.8-1): 1, the content of total protein is 8-25 wt%, and total carbon-water content is 20-75 wt%; and relative to 100 parts by weight of the flaxseed, the content of the chia seeds is 40-70 parts, the content of the almonds is 90-140 parts, the content of the A component is 40-65 parts and the content of the B component is 20-45 parts.The product can effectively regulate blood sugar, has good taste and no side effects, and can be eaten as meal replacements.

Owner:深圳市瑞辰健康管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com