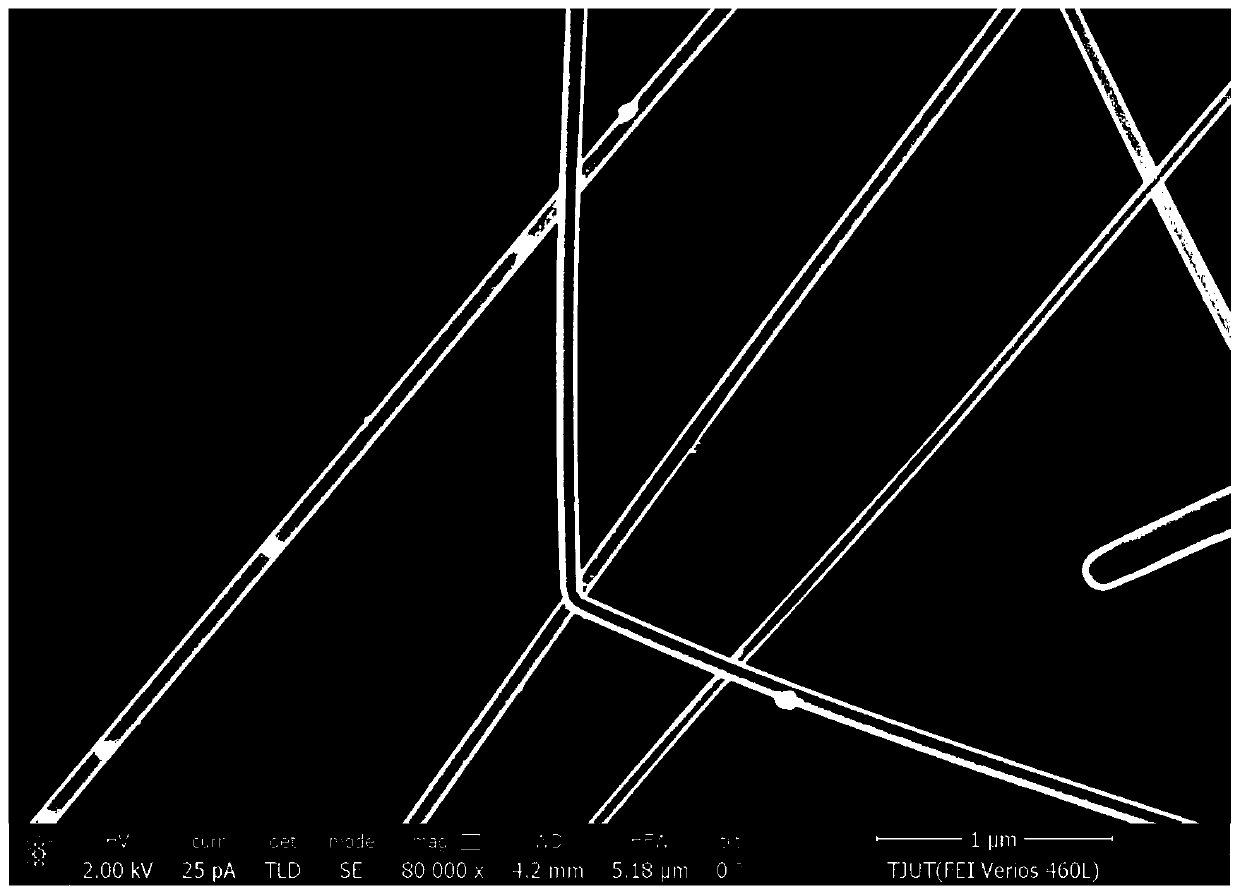

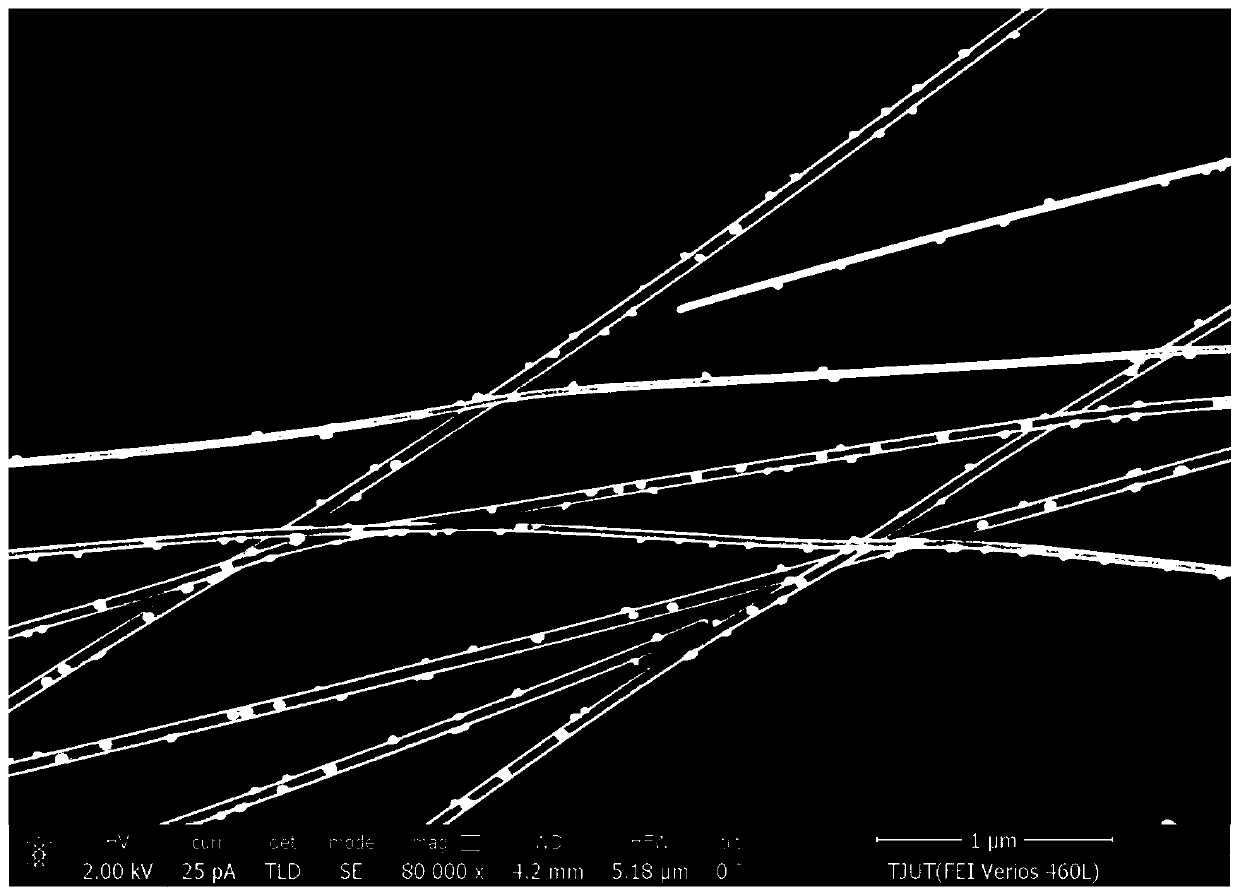

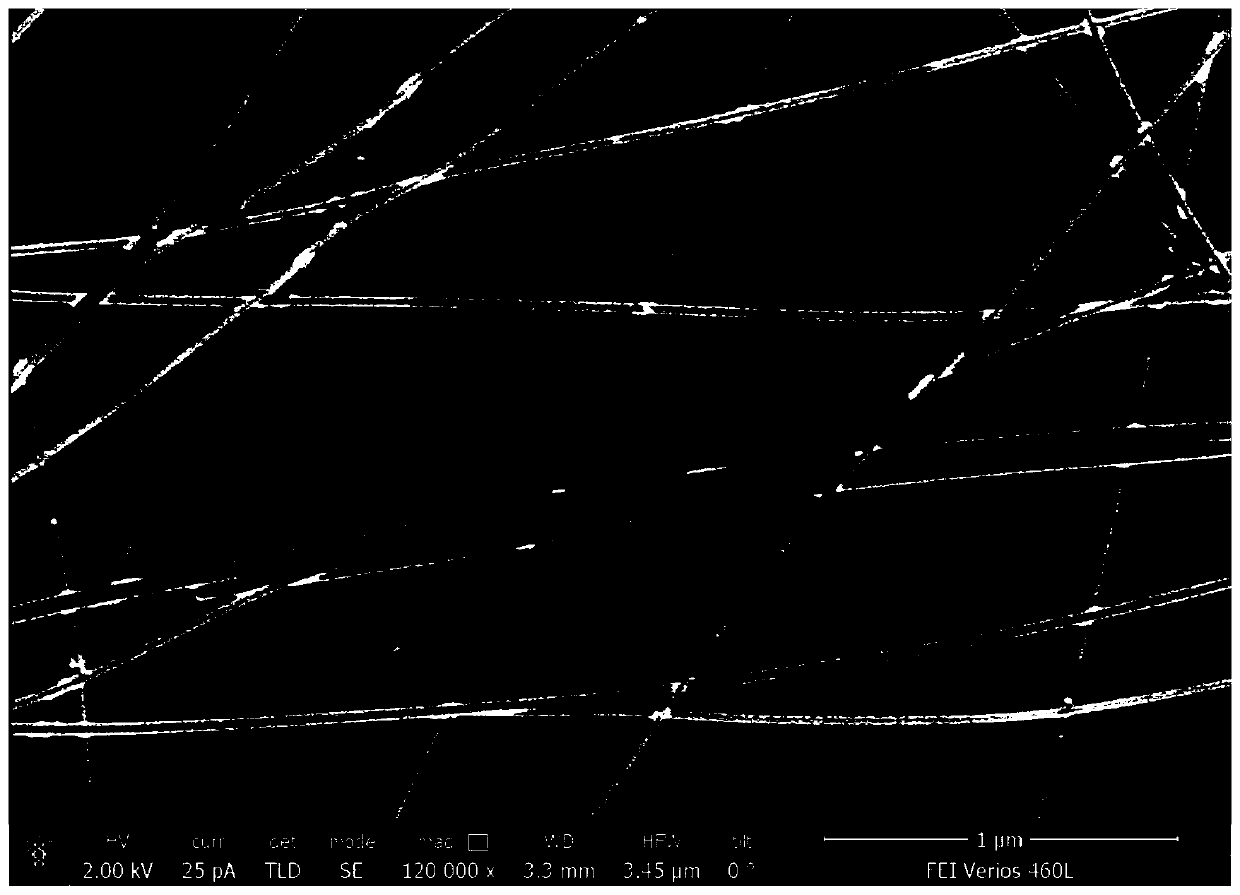

Nanometer silver wire as well as preparation method and application thereof

A technology of nano-silver wire and silver nitrate, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex operation, high volatility, easy to pollute the environment, etc., and achieve simplified preparation process , Uniform diameter and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for preparing silver nanowires, comprising the following steps performed in sequence:

[0043] Step 1: Add 0.08mmol potassium chloride, 0.06mmol potassium bromide, 0.0018mmol ferric chloride, 0.014mmol aluminum chloride and 28mmol polyvinylpyrrolidone (average molecular weight: 1300000) to 190mL ethylene glycol to obtain mixed solution A;

[0044] Step 2: heating the mixed solution A to the nucleation temperature and keeping it warm for 30 minutes, the nucleation temperature is 140°C;

[0045] Step 3: add the ethylene glycol solution (10mL) of 14mmol silver nitrate in described mixed solution A to obtain mixed solution B;

[0046] In the mixed solution B, the concentration of potassium chloride is 0.4mmol / L, the concentration of potassium bromide is 0.3mmol / L, the concentration of ferric chloride is 0.009mmol / L, and the concentration of aluminum chloride is 0.07mmol / L. The concentration of vinylpyrrolidone was 140mmol / L, and the concentration of silver nitrate...

Embodiment 2

[0056] A method for preparing silver nanowires, comprising the following steps performed in sequence:

[0057] Step 1: Add 0.08mmol potassium chloride, 0.06mmol potassium bromide, 0.0018mmol ferric chloride, 0.014mmol aluminum chloride, 28mmol polyvinylpyrrolidone (average molecular weight: 1300000) to 190mL ethylene glycol to obtain mixed solution A;

[0058] Step 2: heating the mixed solution A to the nucleation temperature and keeping it warm for 30 minutes, the nucleation temperature is 150°C;

[0059] Step 3: add the ethylene glycol solution (10mL) of 14mmol silver nitrate in described mixed solution A to obtain mixed solution B;

[0060] In the mixed solution B, the concentration of potassium chloride is 0.4mmol / L, the concentration of potassium bromide is 0.3mmol / L, the concentration of ferric chloride is 0.009mmol / L, and the concentration of aluminum chloride is 0.07mmol / L. The concentration of vinylpyrrolidone was 140mmol / L, and the concentration of silver nitrate wa...

Embodiment 3

[0066] A method for preparing silver nanowires, comprising the following steps performed in sequence:

[0067] Step 1: Add 0.12mmol potassium chloride, 0.06mmol potassium bromide, 0.0018mmol ferric chloride, 0.004mmol aluminum sulfate, 28mmol polyvinylpyrrolidone (average molecular weight: 1300000) to 190mL ethylene glycol to obtain mixed solution A;

[0068] Step 2: heating the mixed solution A to the nucleation temperature and keeping it warm for 30 minutes, the nucleation temperature is 150°C;

[0069] Step 3: add the ethylene glycol solution (10mL) of 14mmol silver nitrate in described mixed solution A to obtain mixed solution B;

[0070] In the mixed solution B, the concentration of potassium chloride is 0.6mmol / L, the concentration of potassium bromide is 0.3mmol / L, the concentration of ferric chloride is 0.009mmol / L, the concentration of aluminum sulfate is 0.02mmol / L, polyethylene The concentration of pyrrolidone was 140mmol / L, and the concentration of silver nitrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com