Method for separating and purifying citicoline in issatchenkia orientalis biotransformation liquid

A technology for separation and purification of citicoline, applied in the field of bioseparation, which can solve the problems of severe loss, complicated process, and failure to recycle cytidylic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

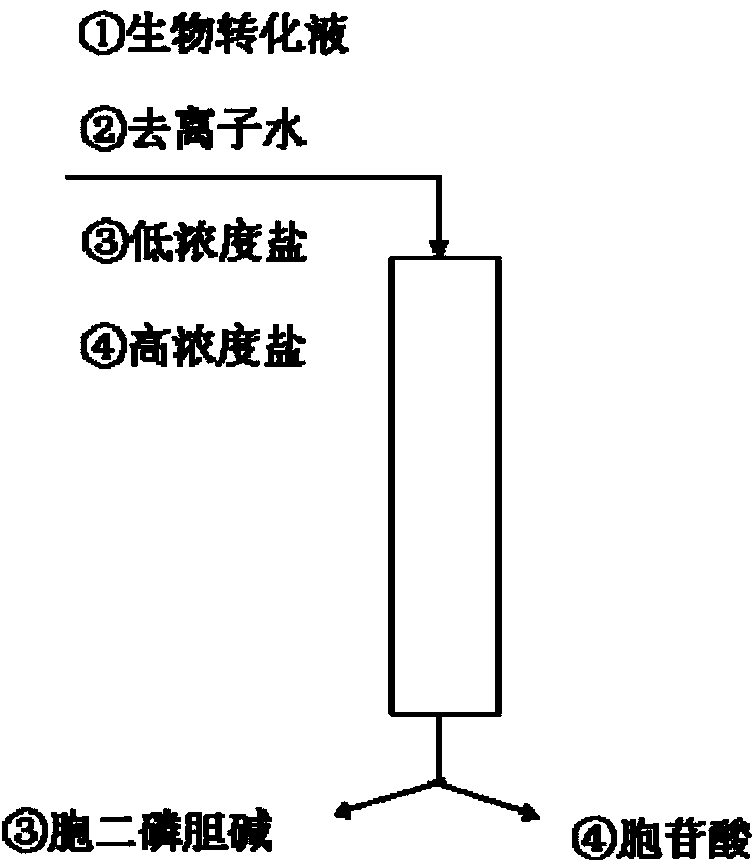

Image

Examples

Embodiment 1~ Embodiment 3

[0022] The preparation method of the I. orientalis citicoline biotransformation liquid in the following examples 1 to 3 is as follows:

[0023] Glucose is used as the energy donor, on the one hand to provide the energy demand of the bacteria, on the other hand to provide ATP for the citicoline synthetase system; to change the metabolic flow direction by adding one or a combination of potassium ions, magnesium ions and manganese ions , improve the regeneration efficiency of ATP, so as to match the rate of citicoline enzyme system, and realize the efficient preparation of citicoline. (Refer to the following patent documents for the specific preparation method: Zhang Liang, Shi Guiyang, You Cuiping, etc. A strain of Issaccharomyces orientalis and its whole cell transformation method to produce citicoline: China, CN102286386A[P].2011- 12-21.), among which I. orientalis Z1 was purchased from China Culture Collection Center, and the strain number is: CCTCC NO: 2011272.

[0024] The...

Embodiment 1

[0026] 300mL I. orientalis citicoline biotransformation solution, containing 1350mg of CDP-c, 650mg of cytidylic acid, 3750mg of phosphate, 500mg of calcium phosphocholine, and 900mg of sulfate.

[0027] (1) Pass the above citicoline biotransformation solution through 717HCO 3 - Type anion exchange resin column, the column size is 20×300mm, the column volume is 60mL, the flow rate of the upper column is 0.5mL / min, and the total amount of the column is 13.5% (mass ratio) of the total exchanged amount of the column.

[0028] (2) After loading the column, rinse the exchange column with 300mL deionized water to wash away unadsorbed substances until the effluent is completely water.

[0029] (3) Wash the column with 0.03M sodium chloride solution until the effluent at the outlet of the column no longer contains CDP-c, and collect 200 mL of the eluate to obtain a high-purity CDP-c solution.

[0030] (4) Wash the column with 0.3M sodium chloride solution until the effluent at the o...

Embodiment 2

[0033] 1000mL I. orientalis citicoline biotransformation solution, containing citicoline 4500mg, cytidylic acid 2039mg, phosphate 11380mg, phosphorylcholine calcium 1520mg, sulfate 2750mg.

[0034] (1) Pass the above citicoline biotransformation solution through 717HCO 3 -Type anion exchange resin column, the column size is 30×500mm, the column volume is 200mL, and the column flow rate is 1.0mL / min. The total amount on the column is 12.8% (mass ratio) of the total amount exchanged by the column.

[0035] (2) After loading the column, rinse the exchange column with 1000mL deionized water to wash away unadsorbed substances until the effluent is completely water.

[0036] (3) Wash the column with 0.04M sodium chloride solution until the effluent at the column outlet no longer contains CDP-c, and collect 800 mL of the eluent to obtain a high-purity CDP-c solution.

[0037] (4) Wash the column with 0.2M sodium chloride solution until the effluent at the outlet of the column no l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com