Treatment method of exhaust gas generated in olive leaf extract product production

A technology of olive leaf extract and processing method, which is applied in separation methods, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as unsatisfactory effects, achieve obvious effects, save costs, and shorten process time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

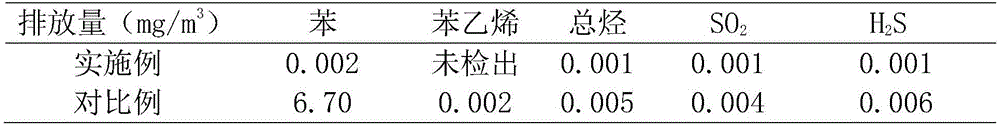

Examples

Embodiment 1

[0025] A treatment method for waste gas in the production of olive leaf extract, comprising the steps of:

[0026] 1) Spray tower absorption: the waste gas generated during production is concentrated and then enters the spray tower for treatment;

[0027] The spray tower is two stages connected in series. The two-stage spray tower is equipped with fillers. The liquid phase substance in the spray tower is water. The two-stage spray tower plays a protective role and is connected with the subsequent process treatment;

[0028] 2) The processed gas is transported through pipelines to the chimney in the factory for high-altitude discharge;

[0029] Described filler is prepared by the following method:

[0030] a. Raw material preparation: prepare fiber silk and lychee skin according to the weight ratio of 90:10;

[0031] b. Treatment of lychee skin:

[0032] ① Grinding treatment: After crushing or crushing, add pure water equivalent to 8-10 weight of lychee skin, process it with...

Embodiment 2

[0037] A treatment method for waste gas in the production of olive leaf extract, comprising the steps of:

[0038] 1) Spray tower absorption: the waste gas generated during production is concentrated and then enters the spray tower for treatment;

[0039] The spray tower is two stages connected in series. The two-stage spray tower is equipped with fillers. The liquid phase substance in the spray tower is water. The two-stage spray tower plays a protective role and is connected with the subsequent process treatment;

[0040] 2) The processed gas is transported through pipelines to the chimney in the factory for high-altitude discharge;

[0041] Described filler is prepared by the following method:

[0042] a. Raw material preparation: prepare fiber silk and lychee skin according to the weight ratio of 92:8;

[0043] b. Treatment of lychee skin:

[0044] ① Grinding treatment: After crushing or crushing, add pure water equivalent to 8-10 weight of lychee skin, process it with a ...

Embodiment 3

[0049] A treatment method for waste gas in the production of olive leaf extract, comprising the steps of:

[0050] 1) Spray tower absorption: the waste gas generated during production is concentrated and then enters the spray tower for treatment;

[0051] The spray tower is two stages connected in series. The two-stage spray tower is equipped with fillers. The liquid phase substance in the spray tower is water. The two-stage spray tower plays a protective role and is connected with the subsequent process treatment;

[0052] 2) The processed gas is transported through pipelines to the chimney in the factory for high-altitude discharge;

[0053] Described filler is prepared by the following method:

[0054] a. Raw material preparation: prepare fiber silk and lychee skin according to the weight ratio of 95:5;

[0055] b. Treatment of lychee skin:

[0056] ① Grinding treatment: after crushing or crushing, add pure water equivalent to 8-10 weight of lychee skin, process it with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com