Method for immobilization of titanium dioxide and application of titanium dioxide

A titanium dioxide and silicon dioxide technology, applied in chemical instruments and methods, chemical/physical processes, special compound water treatment, etc., can solve the problems affecting catalyst firmness, catalyst shedding, etc. The effect of good catalytic degradation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Mix the binder silica sol and P25 according to the mass ratio of silicon dioxide and titanium dioxide of the silica sol is 3:4, add 10 mL of water, stir for 10 min, add 2% of the mass of titanium dioxide as a dispersant sodium hexametaphosphate , mixed and stirred for 3 h, sprayed on the pretreated aluminum alloy mesh with a spray gun, and dried in an oven at 160 °C for 1 h to obtain a silica sol-supported titania catalyst.

Embodiment 2

[0063] A method for immobilizing titanium dioxide, comprising the steps of:

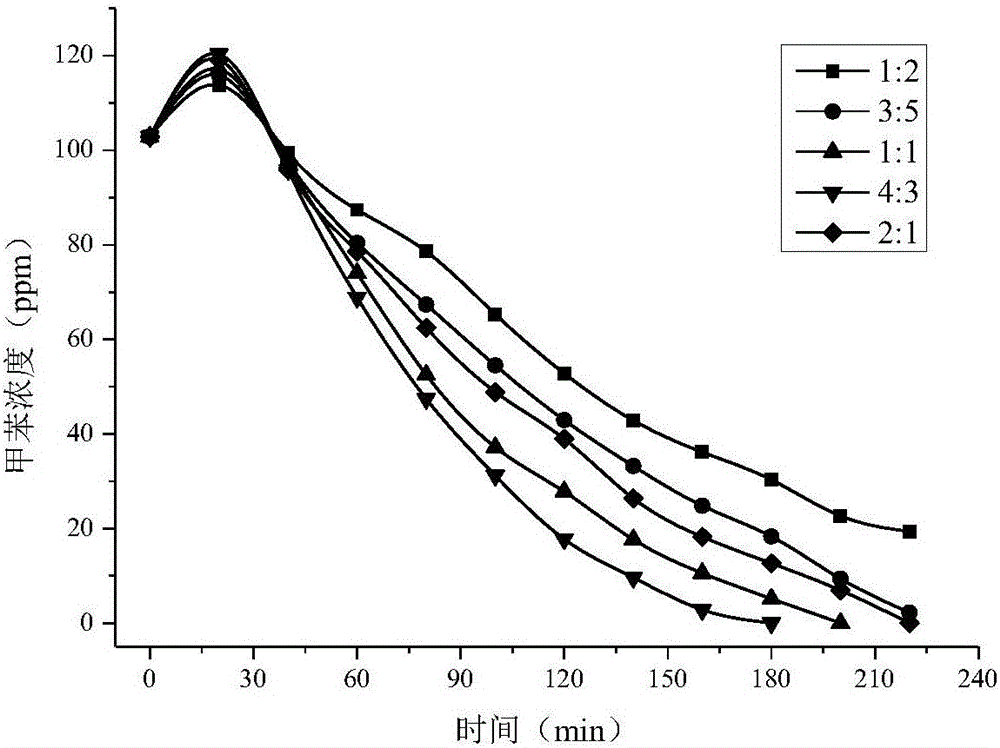

[0064] Step S1: After uniformly mixing 25 g of silica sol and silane coupling agent KH-570, adjust the pH to 2 with hydrochloric acid, add titanium dioxide, add 10 mL of water, stir for 10 min, and stir well; wherein, the titanium dioxide and silica sol The mass ratio of silicon dioxide in the medium is 1:2, 3:5, 1:1, 4:3, 2:1 to carry out experiments respectively, and titanium dioxide is immobilized;

[0065] Step S2: Add sodium hexametaphosphate, the amount of sodium hexametaphosphate is 2% of the mass of titanium dioxide, mix and stir for 1 hour, spray it on the pretreated aluminum alloy mesh with a spray gun, and dry it in an oven at 160°C for 1 hour h, obtaining a silica sol immobilized titania catalyst.

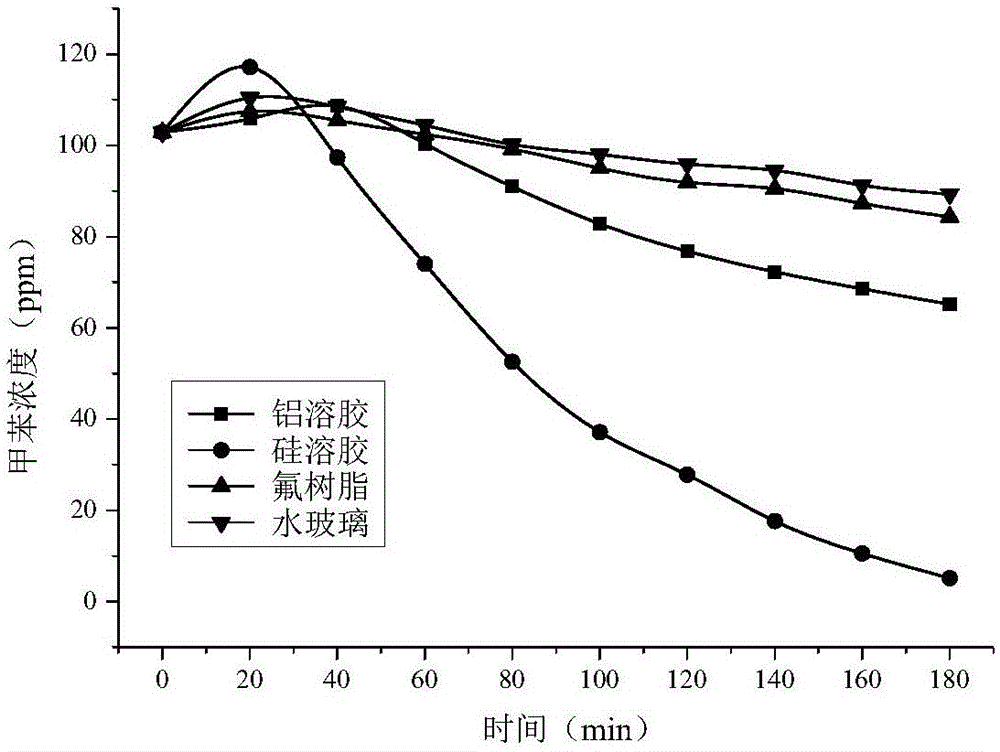

[0066] image 3 It is the effect curve of toluene degradation by catalysts loaded with different mass ratios of titanium dioxide and silicon dioxide. from image 3 It can be seen that with...

Embodiment 3

[0070] The particle size of the photocatalyst has a great influence on the catalyst, and the smaller particle size can generally make the catalyst show better photocatalytic effect. In the process of immobilizing the catalyst by the bonding method, the dispersion of titanium dioxide particles in the binder has a great influence on the photocatalyst.

[0071] Therefore, in the process of preparing the photocatalyst by the bonding method, different dispersants were added, including sodium hexametaphosphate, sodium hexametasilicate, sodium cetylbenzenesulfonate, and polyethylene glycol. The experimental method of concrete catalyst immobilization is the same as embodiment 2.

[0072] Image 6 is the influence curve of the degradation of toluene by adding different dispersant immobilized catalysts. from Image 6 It can be seen that the addition of dispersant improves the effect of photocatalyst to a certain extent. From the perspective of comprehensive effects, sodium hexametap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com