Regenerative cleaning solution of denitration catalyst and regeneration method of denitration catalyst

A technology for denitrification catalysts and cleaning fluids, applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor penetration, damage to catalyst structure, and insufficient power, and achieve high stability , good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

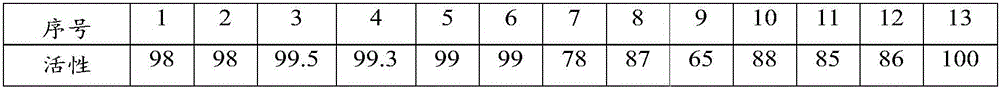

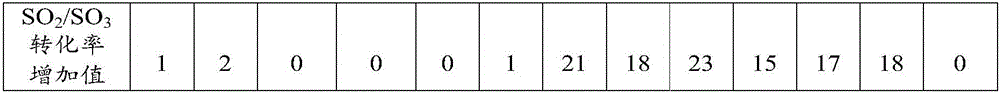

Examples

Embodiment 1

[0048] In this example, first, the same volume of alkylphenol polyoxyethylene ether with a concentration of 0.02g / L and 2g / L of diethylenetriaminepentacarboxylic acid was mixed, and the pH value was adjusted to 4.0 by ammonia water to prepare The regeneration cleaning solution of the denitration catalyst comprising 0.01g / L of low-foaming surfactant and 1g / L of ion complexing agent.

[0049] Secondly, gather the deactivated denitrification catalysts together, use a blower or other air-blowing equipment to purge and remove dust from the deactivated denitrification catalysts, and pay attention to turning over after a period of time during the purging process to ensure deactivation All parts of the denitrification catalyst can be purged.

[0050] Afterwards, the deactivated denitration catalyst was immersed in the regenerated cleaning solution of the denitration catalyst prepared above and immersed for 2 hours under the condition of heating to 15 degrees Celsius, during which comp...

Embodiment 2

[0053] In the present embodiment, at first, the concentration of the same volume is 4g / L dodecyl sulfate and 30g / L butane tetracarboxylic acid are mixed, and the pH value is adjusted to 6.5 by ammonia water, and the preparation comprising 0.02g / L The regeneration cleaning solution of the denitrification catalyst of L low-foaming surfactant and 15g / L ion complexing agent.

[0054] Secondly, gather the deactivated denitrification catalysts together, use a blower or other air-blowing equipment to purge and remove dust from the deactivated denitrification catalysts, and pay attention to turning over after a period of time during the purging process to ensure deactivation All parts of the denitrification catalyst can be purged.

[0055] Afterwards, the deactivated denitration catalyst was immersed in the regenerated cleaning solution of the denitration catalyst prepared above and immersed for 6 hours under the condition of heating to 60 degrees Celsius, during which compressed air ...

Embodiment 3

[0058] In this example, first, the same volume of aliphatic amine alkylamine polyoxyethylene ether with a concentration of 0.1 g / L and 6 g / L of cyclopentanetetracarboxylic acid was mixed, and the pH value was adjusted to 4.5 by ammonia water to prepare The regeneration cleaning solution of the denitrification catalyst comprising 0.05g / L of low-foaming surfactant and 3g / L of ion complexing agent.

[0059] Secondly, gather the deactivated denitrification catalysts together, use a blower or other air-blowing equipment to purge and remove dust from the deactivated denitrification catalysts, and pay attention to turning over after a period of time during the purging process to ensure deactivation All parts of the denitrification catalyst can be purged.

[0060] Afterwards, the deactivated denitration catalyst was immersed in the regenerated cleaning solution of the denitration catalyst prepared above and heated to 25 degrees Celsius for 3 hours, during which compressed air was intr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com