A Pulping Process of Continuous Casting Mold Mold Flux

A continuous casting mold and mold slag technology, applied in the field of mold slag preparation, can solve problems such as segregation of carbonaceous materials, and achieve the effects of enhancing surface tension, rational space design, and preventing flocculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

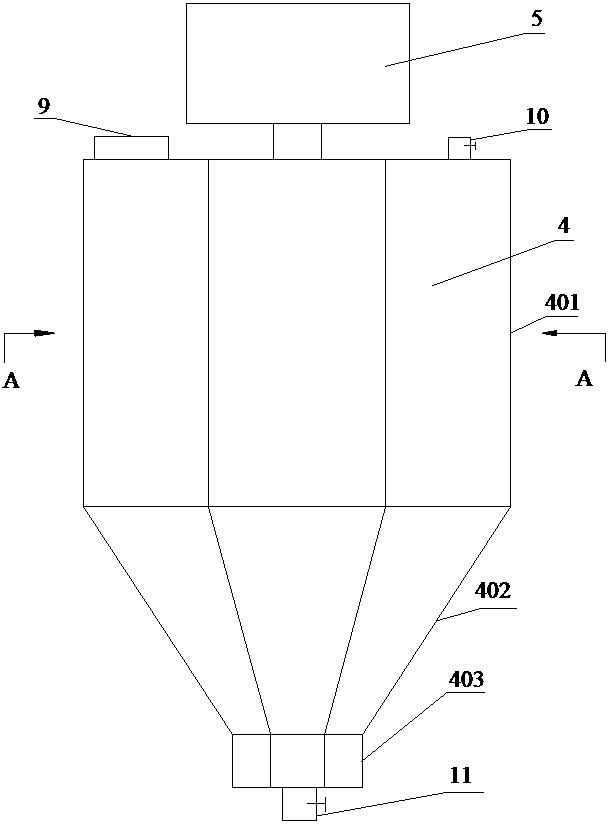

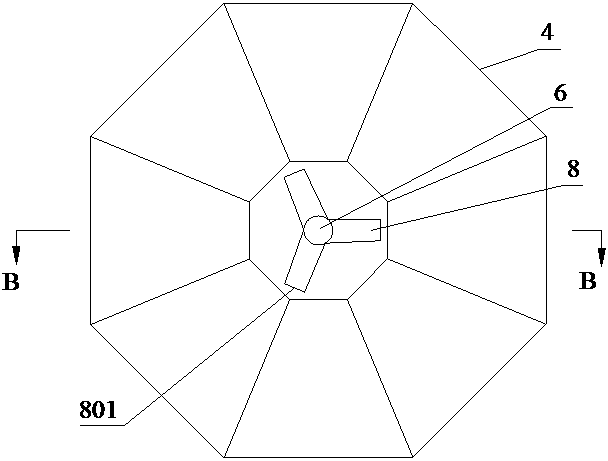

[0033] refer to Figure 2~4, a pulping process of continuous casting crystallizer powder, which is completed by using a pulping machine and a water mill in sequence. The structure of the pulping machine used is as follows: the pulping machine includes a pulping bin 4, a driving mechanism 5 and a stirring mechanism , the upper part of the pulping bin is provided with a feed inlet 9 and a water inlet 10, and the lower part is provided with a discharge port 11, and the water inlet and the outlet are respectively provided with flowmeters, and any cross section of the pulping bin is a regular octagon shape, the driving mechanism is arranged on the upper part of the pulping bin and is connected with the stirring mechanism, the stirring mechanism includes a stirring shaft 6 and a stirring impeller 7 arranged at the end of the stirring shaft, and the stirring impeller includes The paddles 8 are evenly distributed along the radial direction of the stirring shaft at an angle of 120°, th...

Embodiment 2

[0039] refer to Figure 3~4 , a pulping process of continuous casting mold powder, which is completed by using a pulper and a water mill in turn. The structure of the pulper used is different from that of Example 1, wherein:

[0040] The projected length of the paddle 8 at the bottom of the pulping silo is less than the vertical distance from the center of the bottom cross section of the pulping silo to any side.

[0041] Under this structure, the paddles can be extended into the bottom of the pulping bin for operation, so that the mold slag material at the bottom can be turned up to achieve full mixing.

Embodiment 3

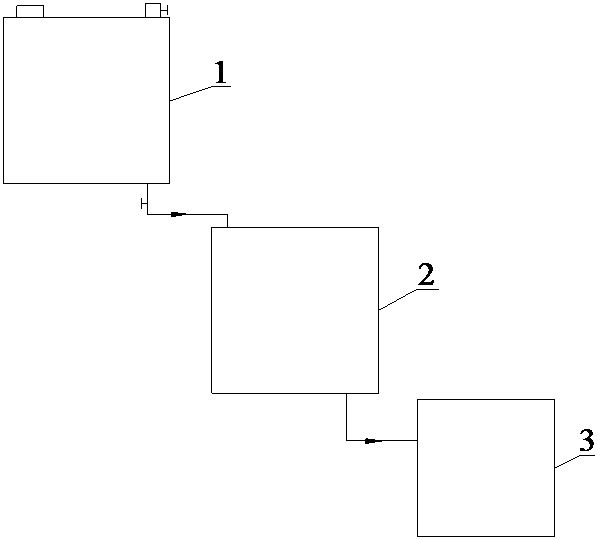

[0043] refer to figure 1 , a pulping process of continuous casting mold powder, which is completed by using a pulper and a water mill in sequence, wherein:

[0044] The height difference between the water mill and the pulping machine is 20-100 cm.

[0045] At the beginning of the process improvement, the present invention uses a pressure pump to pump the slurry from the pulper to the water mill, so that no civil engineering reconstruction or platform support is required, which is also a common method in the existing mold slag water mill pulping process. However, the present invention maintains a height difference of 20 to 100 millimeters between the water mill and the pulp machine after reasonable planning of the pulping machine, water mill and the barrel to be sprayed, and the outlet of the water mill is positioned at the bottom of the barrel to be sprayed. Above, not only the power consumption is saved, but also the cost of civil engineering and platform construction is opt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com