Preparation method for cemented carbide gradient drill point dies having super coarse grains

A cemented carbide, coarse-grained technology, applied in the field of cemented carbide, can solve the problems of composition diffusion, difficult control of product performance consistency, and great differences in diffusion conditions, so as to improve impact resistance, stable product performance, and resistance to Good impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

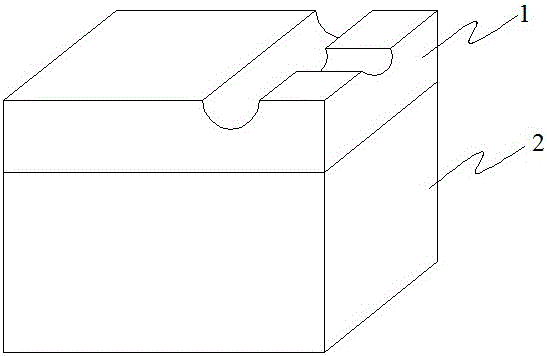

[0017] Please refer to figure 1 , Ultra-coarse grain cemented carbide gradient drill tail die is divided into top layer 1 and bottom layer 2. A preparation method of ultra-coarse-grained cemented carbide gradient drill tail die includes the following steps:

[0018] (1) Prepare the bottom layer mixture: weigh WC powder, Co powder and Cr respectively 3 C 2 Powder for raw material batching, WC powder particle size d bottom It is 9±0.5μm, the mixed raw materials are subjected to wet ball milling. After the wet ball milling is completed, the wet ball milled mixture is subjected to the first wet sieving, and the first sieved mixture is subjected to vacuum Drying, sieving the vacuum-dried mixture for the second time, and then adding wax to dry to obtain the super coarse grained cemented carbide mixture for the bottom layer;

[0019] (2) Prepare the top layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com