Single galvanometer total-reflection type displacement focusing 3D scanning optical system

A total reflection, optical system technology, applied in the field of single galvanometer total reflection displacement focusing 3D scanning optical system, can solve problems such as reducing beam energy utilization, improve laser reflectivity changes, optimize the number of galvanometers, The effect of improving the withstand power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

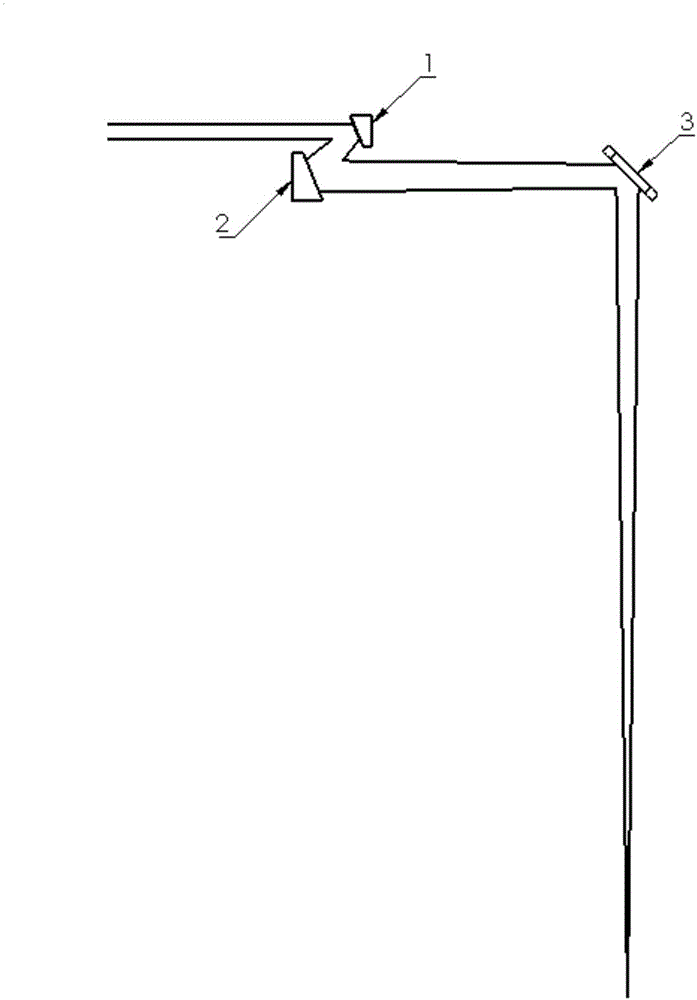

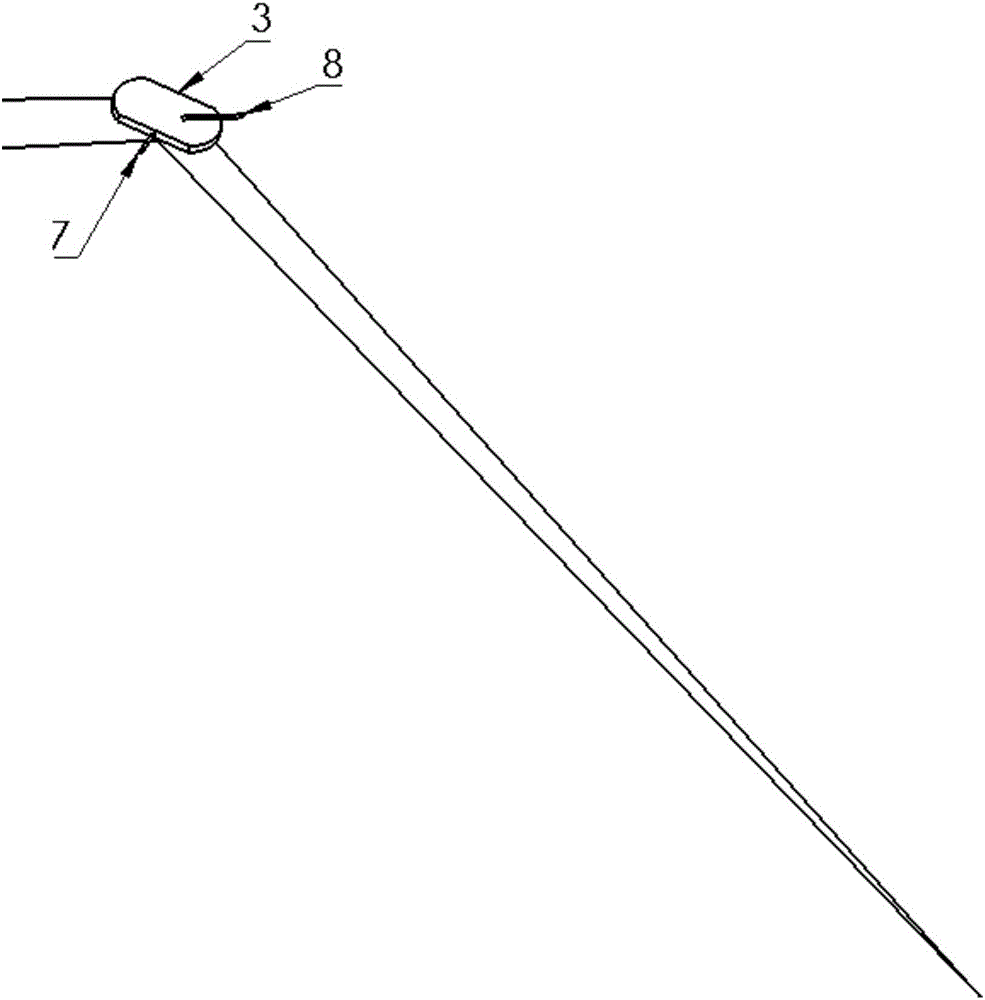

[0033] This embodiment is aimed at fiber optic output lasers. After the fiber laser is output, it is collimated by the off-axis parabolic mirror 4, wherein the position of the light output point of the fiber coincides with the focal point of the off-axis parabolic mirror 4, and the collimated beam passes through the convex off-axis parabolic mirror 1 and After the concave ellipsoid mirror 2 expands and focuses the beam, it passes through the biaxially rotating planar mirror 3 to realize 3D space scanning. At this time, the beam expander combined by the focal length of the convex off-axis parabolic mirror 1 and the concave ellipsoid mirror 2 The focusing module moves horizontally along the incident optical axis to obtain focus compensation at any 3D position.

Embodiment 2

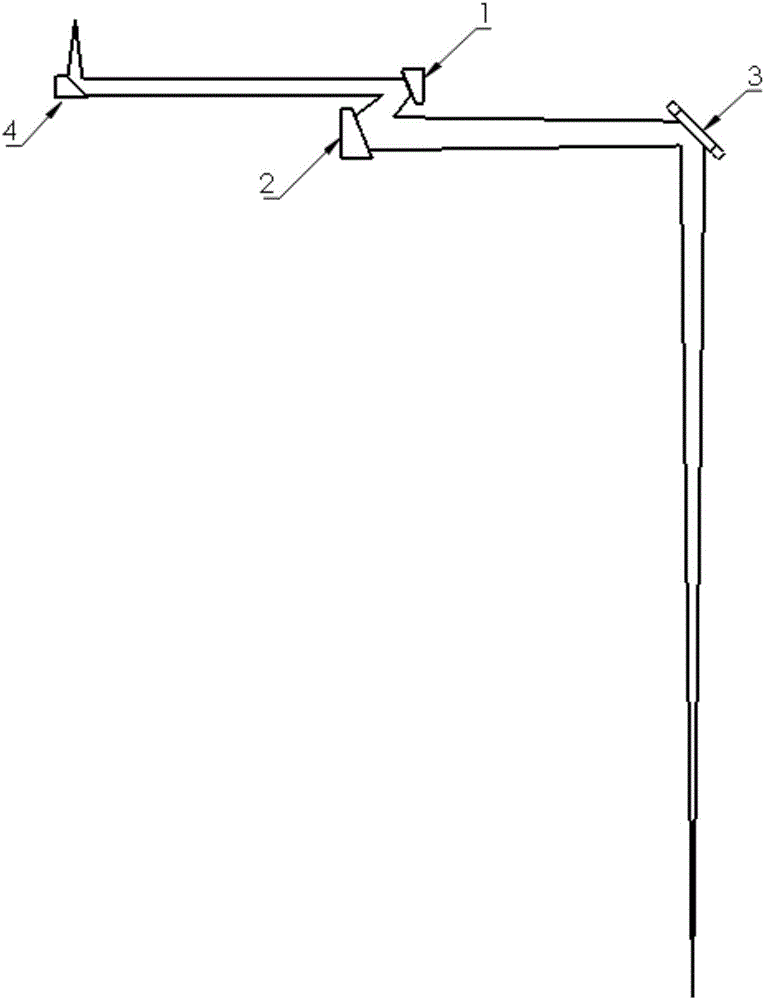

[0035] This embodiment is aimed at freely outputting parallel light beams. The plane reflector 5 and the plane reflector 6 form a beam coaxial adjustment module. Angle deviation and position deviation, so the beam coaxial adjustment system composed of plane mirror 5 and plane mirror 6 is required to adjust the beam coaxially, and then through the convex off-axis parabolic mirror 1 and the concave ellipsoid mirror 2 to expand the beam and focus, Finally, 3D space scanning is realized through the biaxially rotating planar reflective mirror 3. At this time, the beam expander focusing module combined with the focal length of the convex off-axis parabolic mirror 1 and the concave ellipsoid mirror 2 moves horizontally along the incident optical axis to obtain Focus compensation at any 3D position.

[0036] The invention has a novel structural design, adopts a single vibrating mirror scanning scheme, optimizes the number of vibrating mirrors while realizing 3D large-scale scanning, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com