Gear indexing circle diameter positioning detection device

A positioning detection device and indexing circle technology, applied in the field of gear hobbing, can solve the problems of increased manufacturing costs, high cost, complex structure, etc., and achieve the effects of reduced processing costs, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

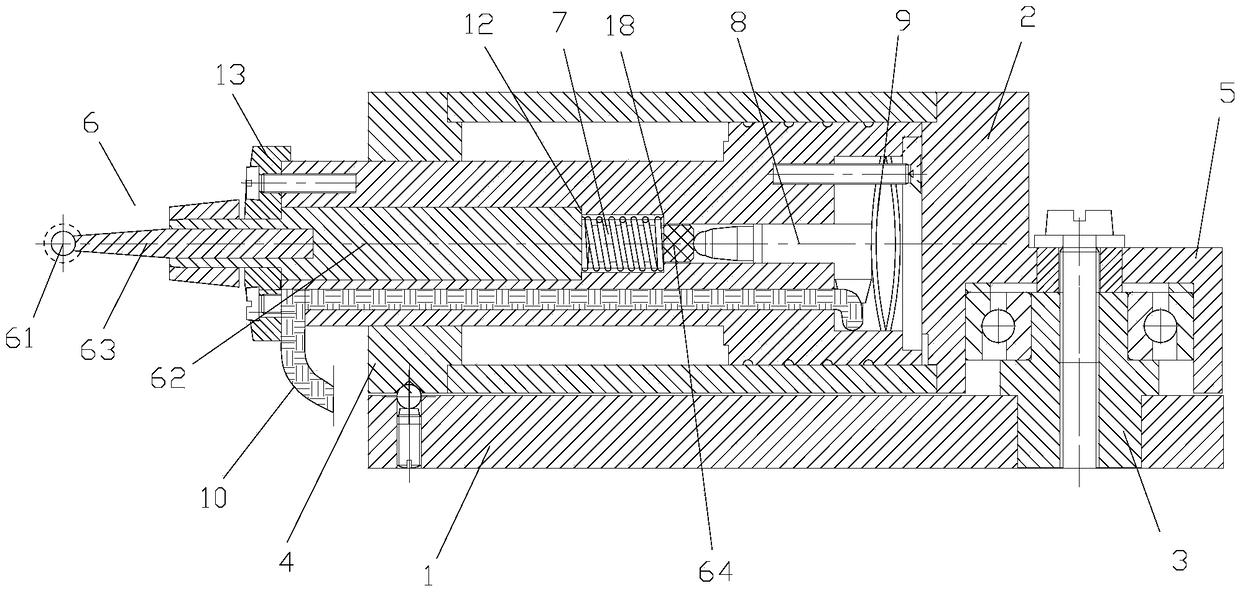

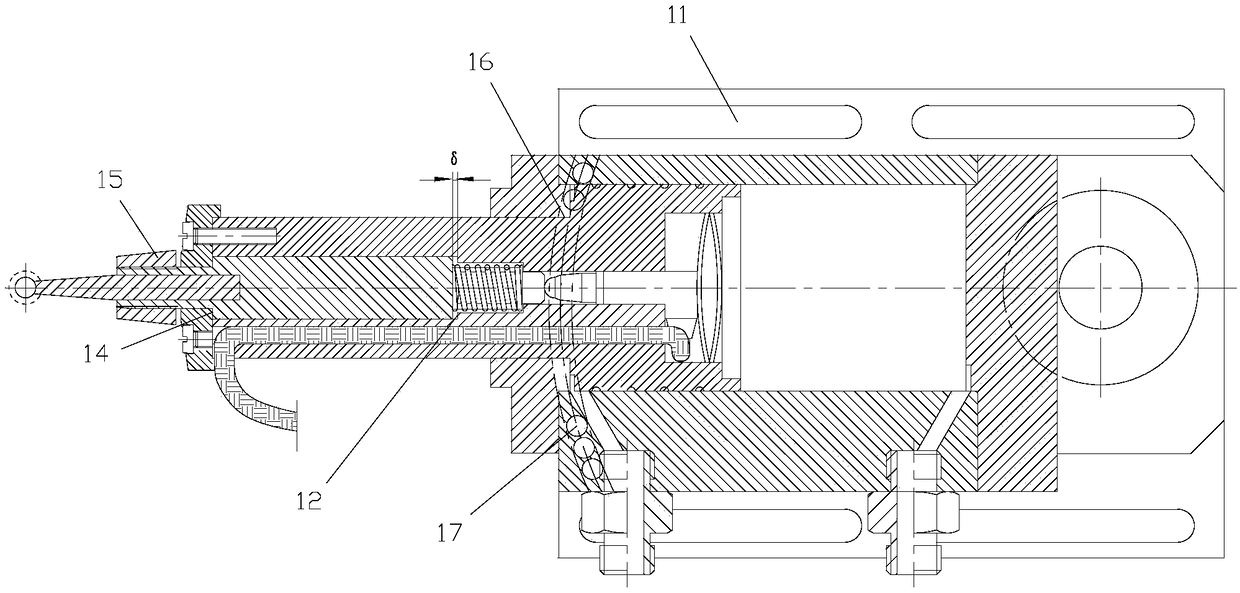

[0019] In the attached picture, figure 1 It is a cross-sectional view of the main viewing direction of the present invention, figure 2 Take the horizontal plane where the center of the ball head and the axis of the piston rod are located as the section to remove figure 1 Top view of the upper part. The gear pitch circle diameter positioning detection device in this embodiment includes a base 1 and an oil cylinder 2, and the base is provided with a rotating shaft 3, a rotating disc 4 concentric with the rotating shaft and an arc-shaped chute 16 concentric with the rotating shaft , the rotary disc and the oil cylinder are integrally arranged, the oil cylinder is rotatably connected with the rotating shaft through the connecting part 5 integrally arranged with it, and rotates around the rotating shaft through the rolling ball 17 arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com