Composite type robot using auxiliary rod to climb rod

A composite, robotic technology, applied in the direction of manipulators, motor vehicles, program-controlled manipulators, etc., can solve the problems of inability to adapt to straight pole crawling, restricted, and the rods of different thicknesses cannot stably fix the climbing pole range, etc., and achieve the working position. Flexible and variable, lightweight, lightweight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

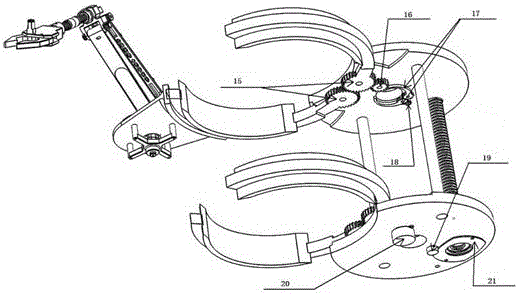

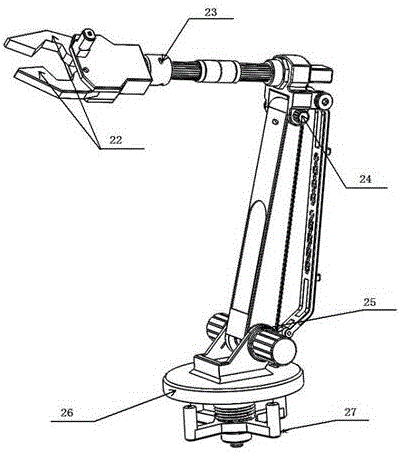

[0025] The present invention accords with the robot and climbs on the utility pole through the auxiliary pole, and realizes the inspection task to the power transmission line, and the specific realization process is:

[0026] Set the composite robot on the auxiliary rod 29, the auxiliary rod is set according to the preset position, fixed by the auxiliary rod base 28, and the terminal points to the target utility pole, when the upper small clamp 17 clamps the auxiliary rod, the lower small clamp 8 releases the auxiliary rod At the same time, the motor drives the second gear 10 to drive the first gear 9, and the first gear 9 rises along the transmission screw 11, driving the lower plate to move upward as a whole. At this time, the transmission screw 11 extends out of the lower base to shorten the distance between the two plates When climbing to the highest point, the synchronous large clamp clamps the target through the remote control device Telephone poles, at the same time, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com