Carbon fiber tube forming device and method for processing carbon fiber tube

A carbon fiber tube and forming device technology, applied in the field of carbon fiber tube processing and carbon fiber tube forming device, can solve the problems of small sizing amount, high processing cost, low bonding fastness, etc. effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

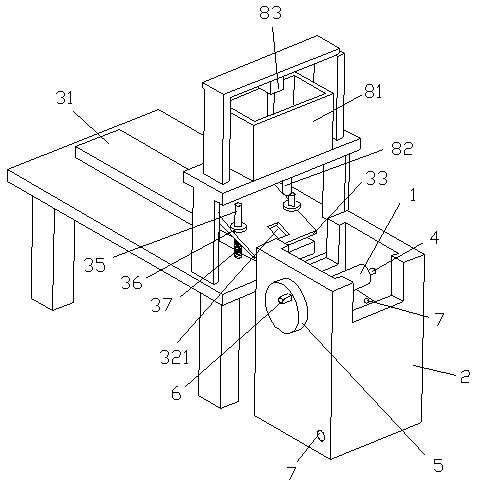

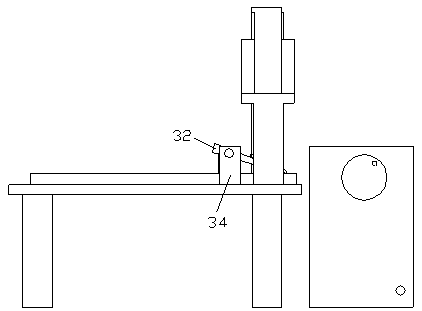

[0035] Such as Figure 1-2 As shown, the present invention discloses a carbon fiber tube forming device, which includes a mandrel 1, a support seat 2, and a press-down coating device. The mandrel 1 is rotatably connected with the support base 2 , and the mandrel 1 is used for winding the carbon fiber cloth onto the mandrel 1 . The press-down coating device is used for coating the coating onto the carbon fiber cloth.

[0036] Pressing down coating device comprises flat plate 31, lower pressing plate 32, scraper 33, bearing 34, lead screw rod 35, press down nut 36, compression spring 37 that cooperate with lead screw rod 35. One end of the lower pressing plate 32 is hinged to the support 34 , the other end of the lower pressing plate 32 is provided with a scraper 33 , and the flat plate 31 is located below the scraper 33 . A compression spring 37 is provided between the lower pressing plate 32 and the flat plate 31 . The compression spring 37 can be sleeved on the lead screw ...

Embodiment 2

[0049] A method for processing carbon fiber tubes using the carbon fiber tube forming device described in Embodiment 1, comprising the following steps:

[0050] (1) Put the carbon fiber cloth flat on the flat plate, make sure that the side to be coated with the glue is facing up, and coat a layer of release agent on the surface of the mandrel.

[0051] (2) Adjust the pressing degree of the lower pressing plate, and feed the adhesive on the cloth.

[0052] (3) Pull the cloth, attach the glued side to the mandrel, turn the mandrel, and drive the cloth to be wound on the mandrel continuously, and at the same time, the scraper continuously coats the glue on the surface of the cloth.

[0053] (4) After the winding is completed, the mandrel is taken out, and the formed carbon fiber tube is pulled out from the mandrel.

[0054] Preferably, the adhesive includes the following raw materials in parts by mass: 60-70 parts of epoxy resin, 20-25 parts of curing agent, and 20-40 parts of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com