Single-sided matte polyester film and preparation method thereof

A technology of polyester film and matt film, applied in the field of polyester film, can solve the problems of single application range, complex process, poor compatibility, etc., and achieve the effect of expanding the application range, wide application range and wide thickness range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of above-mentioned single-sided matt polyester film comprises following processing steps:

[0031] (1) Mixing process: Accurately weigh the weight of each raw material component through a belt scale, and then mix and feed into the extruder;

[0032](2) Control the temperature of the extruder within the range of 230~300°C, stir to make the raw materials fully mixed and melted, and then cast the melt on the cold drum with a high-pressure film to obtain a semi-finished product;

[0033] (3) After the above-mentioned semi-finished product is preheated to exceed the glass transition temperature of polyester by infrared and preheating rollers, it is stretched longitudinally under the condition of infrared lamp irradiation with a longitudinal stretch ratio of 2 to 4 times, cooled and shaped, and then preheated. After the hot roll is preheated, the transverse stretching ratio is 2~5 times, and the shape is set at a temperature of 150~~240°C, and then cool...

Embodiment 1

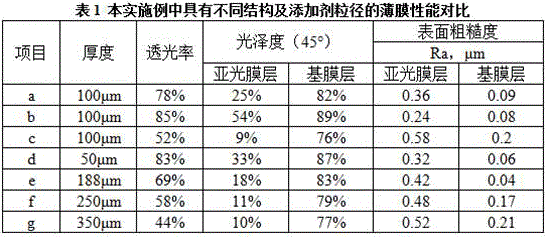

[0036] In this example, the difference in film properties produced by longitudinal comparison of additive masterbatch slices with different mass ratios and different particle sizes in the present invention is described. At the same time, the present invention also compares the performance differences produced by different structures , the following are the specific structures of different experiments, and the performance differences produced by them are listed in Table 1.

[0037] a: The thickness of the polyester film is 100 μm, the base film layer is a common layer, use 30wt% blank polyester chips, 10wt% masterbatch chips and 60wt% production recycling chips; the thickness of the matt film layer is 10μm, Use 65wt% matt masterbatch chip with 3wt% silicon content and 3μm particle size and 20wt% blank polyester chip.

[0038] b: The thickness of the polyester film is 100 μm, the formula of the base film layer is the same as that of a, the thickness of the matt film layer is 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com