Printed electronic printing device supporting flow line production and production system

An electronic printing and assembly line technology, applied in printed circuit, printed circuit manufacturing, printing, etc., can solve the problems of inconvenient clamping of workpieces, failure of assembly line production, and inability to clamp workpieces, etc., to achieve good product quality, realize automatic production, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

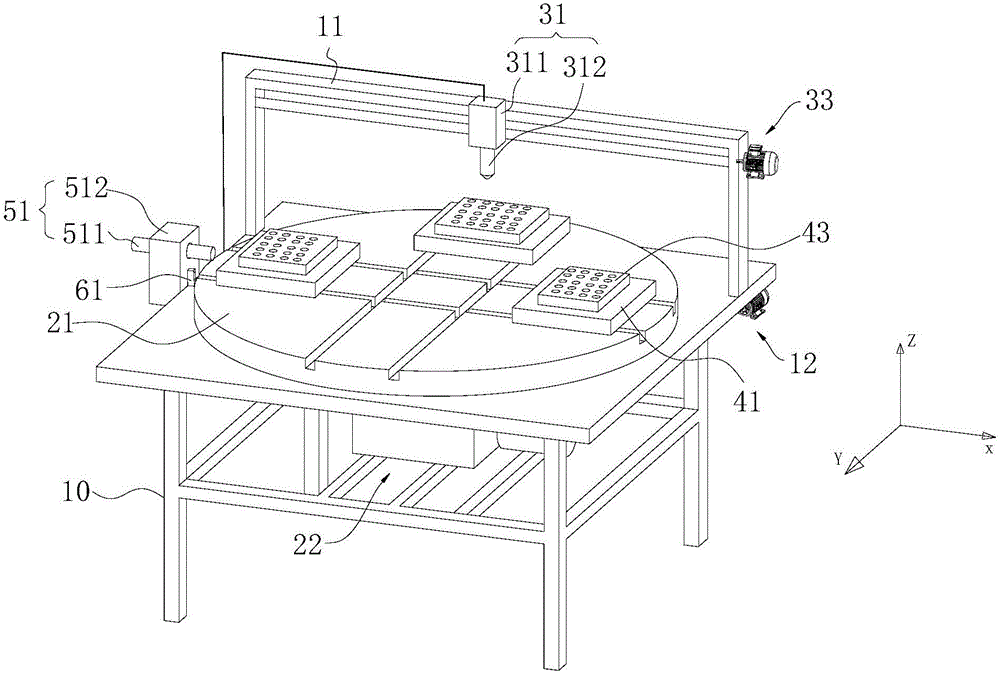

[0040] refer to figure 1 As shown, a printed electronic printing device supporting assembly line production provided by Embodiment 1 of the present invention includes a frame 10 , a jet printing device, a rotating device and a workbench 41 .

[0041] The frame 10 mainly plays the role of supporting other components, and the frame 10 can be made into a frame structure, for example, it can be made by welding rectangular tubes or angle steels. Of course, it can also be connected with bolts. The welded structure is solid and reliable, and the appearance is beautiful; the bolted connection is easy to disassemble and assemble.

[0042] It should be noted that, in this embodiment, the horizontal direction of the rack 10 is defined as the X direction, the longitudinal direction of the rack 10 is defined as the Y direction, and the vertical direction of the rack 10 is defined as the Z direction.

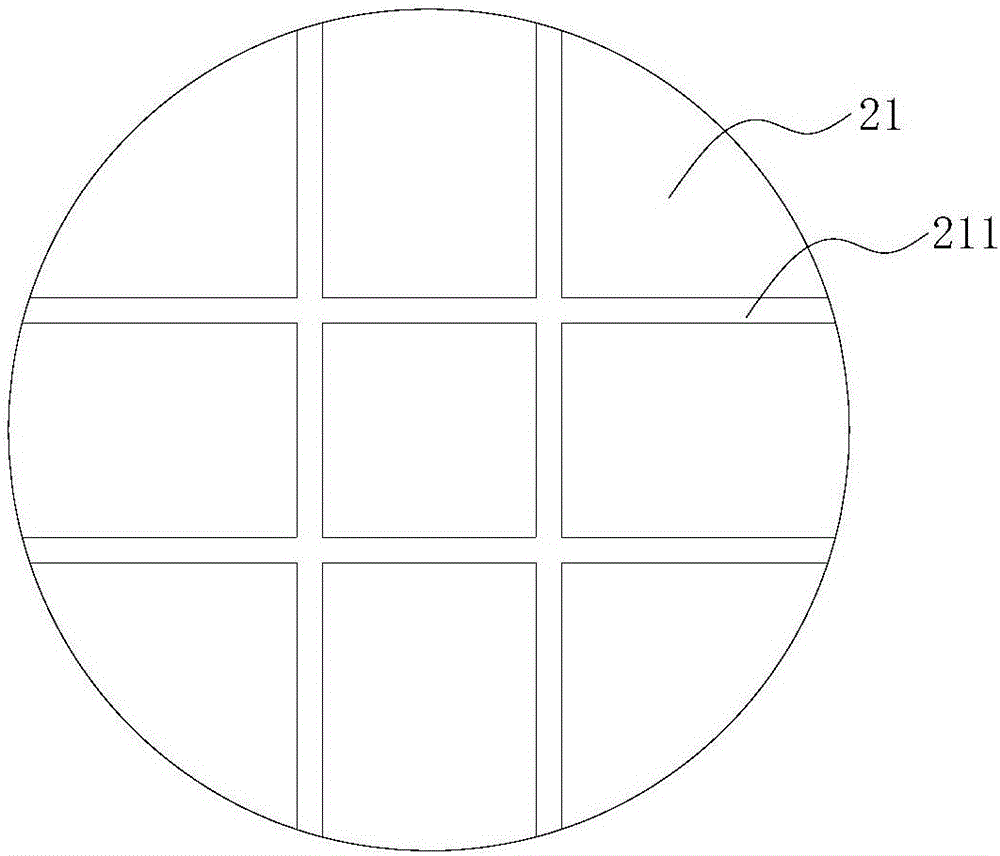

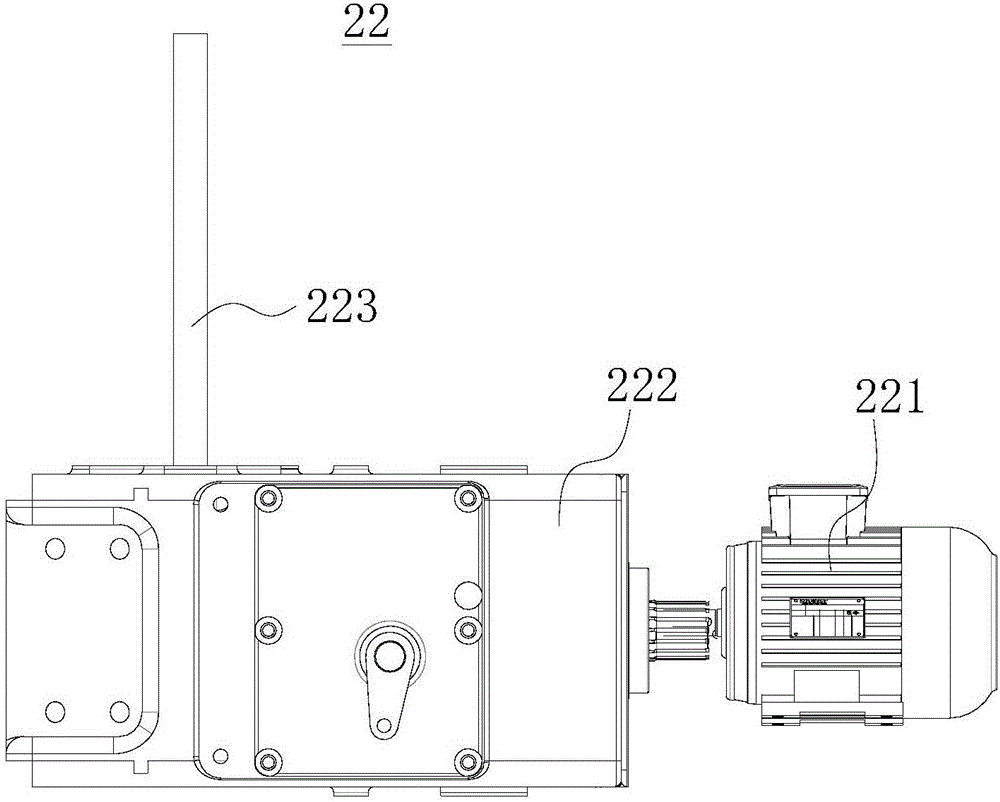

[0043] The rotating device is used to drive the workpiece to rotate, and the rotating d...

Embodiment 2

[0073] A production system provided by Embodiment 2 of the present invention includes a printed electronic printing device supporting assembly line production, hole processing equipment and cleaning equipment.

[0074] It should be noted that the printed electronic printing device supporting assembly line production can adopt the printed electronic printing device supporting assembly line production in Embodiment 1, and its structure, working principle and technical effects can refer to the corresponding content in Embodiment 1 , which will not be described in detail here.

[0075] Both hole processing equipment and cleaning equipment can be selected from existing equipment, or special equipment can be used.

[0076] The production system has high production efficiency, can realize automatic production, has low manufacturing cost, low labor intensity and good quality of produced products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com