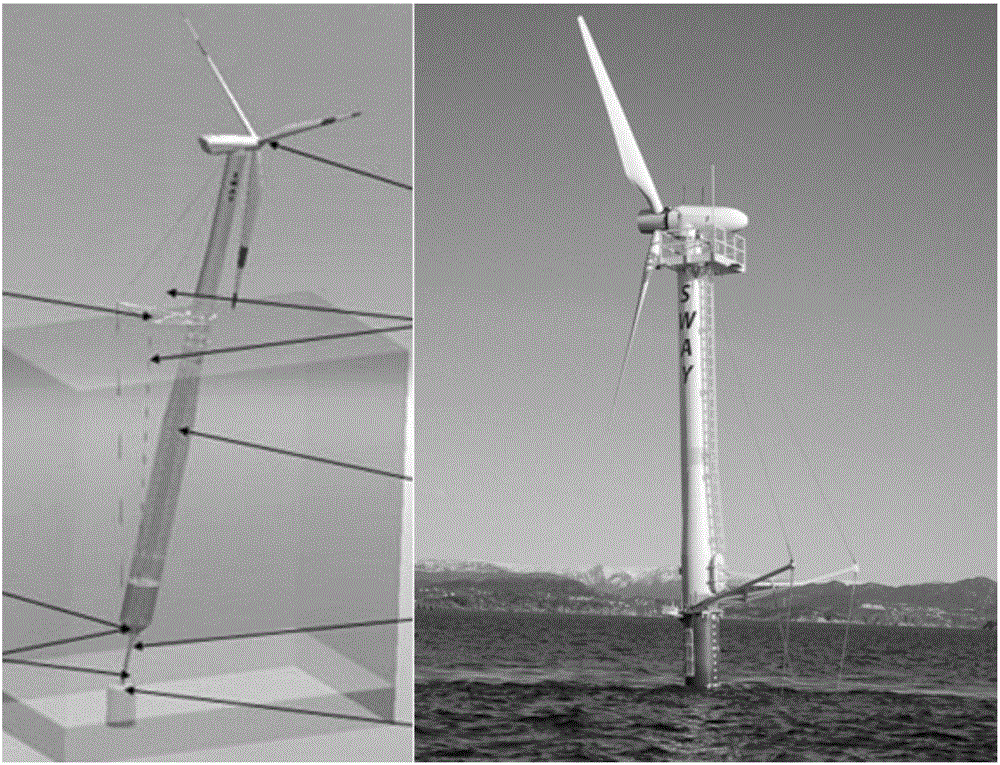

Spar type assembly prestressed reinforced concrete floating offshore wind turbine foundation

A technology for reinforced concrete and offshore wind turbines, which is used in infrastructure engineering, wind power generation, floating buildings, etc. It can solve the problems such as the reduction of foundation stability and the efficiency of wind turbines, and the inability to contribute to stability due to the overturning moment of the wind turbine. Convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

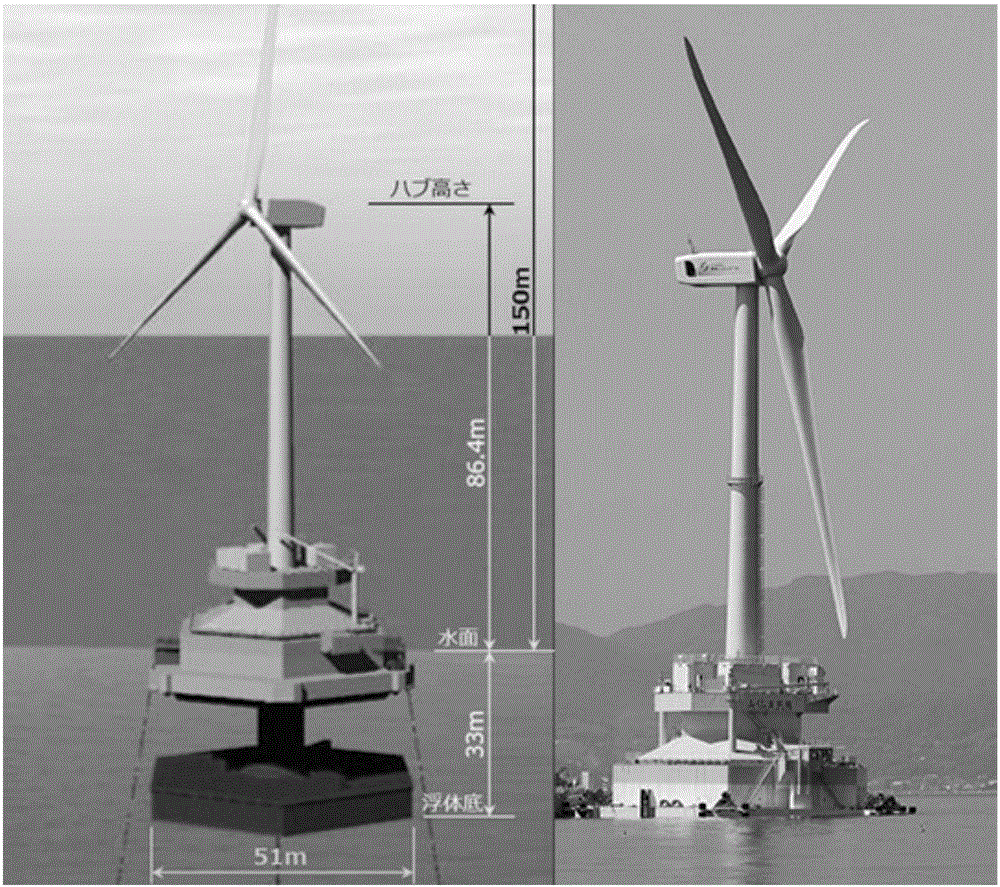

[0034] An embodiment of the present invention will be described in detail below by taking a 5MW horizontal axis wind turbine as an example in conjunction with the accompanying drawings.

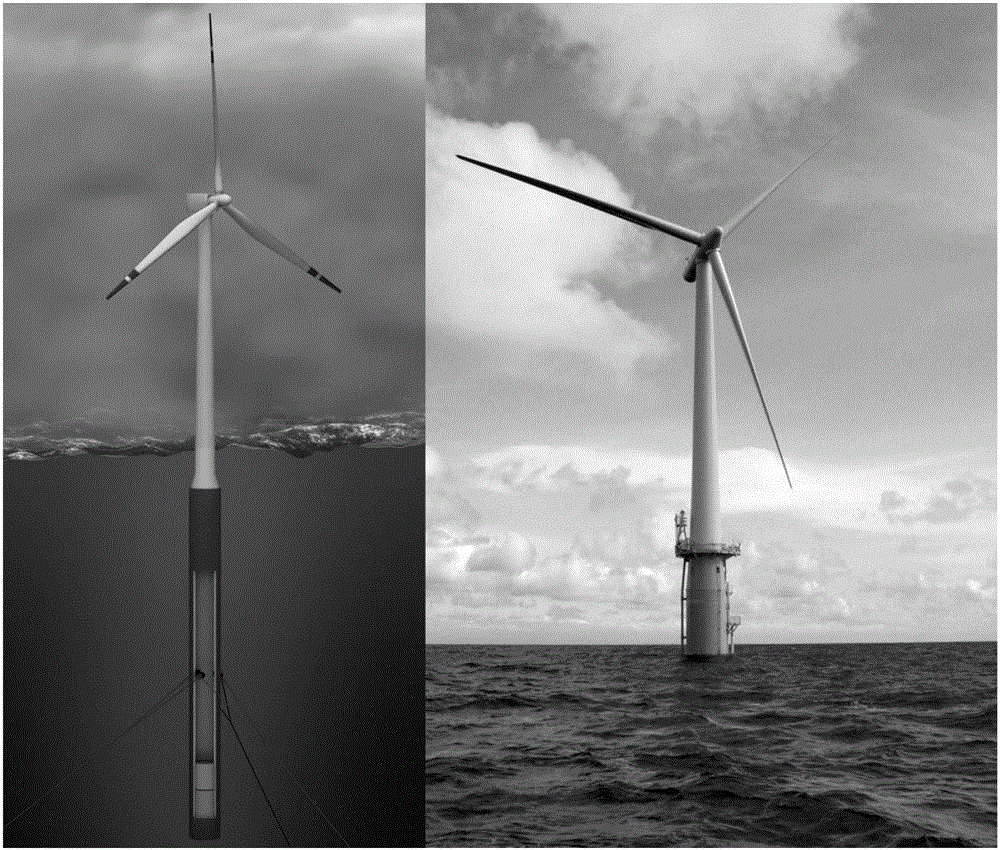

[0035] The present invention proposes a set of offshore wind turbine foundations with a water depth of more than 50 meters, which fully applies the principles of aerodynamics, structural mechanics and hydrodynamics. The state is stable and the self-storage ability is strong.

[0036] Figure 4 It is the isometric view of the foundation of the present invention——Spar type prefabricated prestressed reinforced concrete floating offshore fan, Figure 5 is the present invention - an isometric view of a concrete standard assembly member, Figure 6 It is the sectional view of the present invention---concrete standard assembly member, Figure 7 It is the sectional view of the present invention-concrete ballast assembling member.

[0037] The Spar-type assembled prestressed reinforced concrete flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com