Large-area non-aqueous transferring method of nano material

A nanomaterial, water transfer technology, applied in the direction of nanocarbon, nanotechnology, nanotechnology for materials and surface science, etc., to achieve good fidelity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Attached below Figures 1 to 3 An example of the technical solution of the invention will be described.

[0024] Silicon wafers treated with a plasma cleaning machine, the cleaned silicon wafers are modified in a toluene solution of octadecyltrimethoxysilane at a temperature of 60 degrees Celsius for 12 hours, and a silane-based layer is formed on the surface of the silicon wafers to make the silicon wafers hydrophobic Effect.

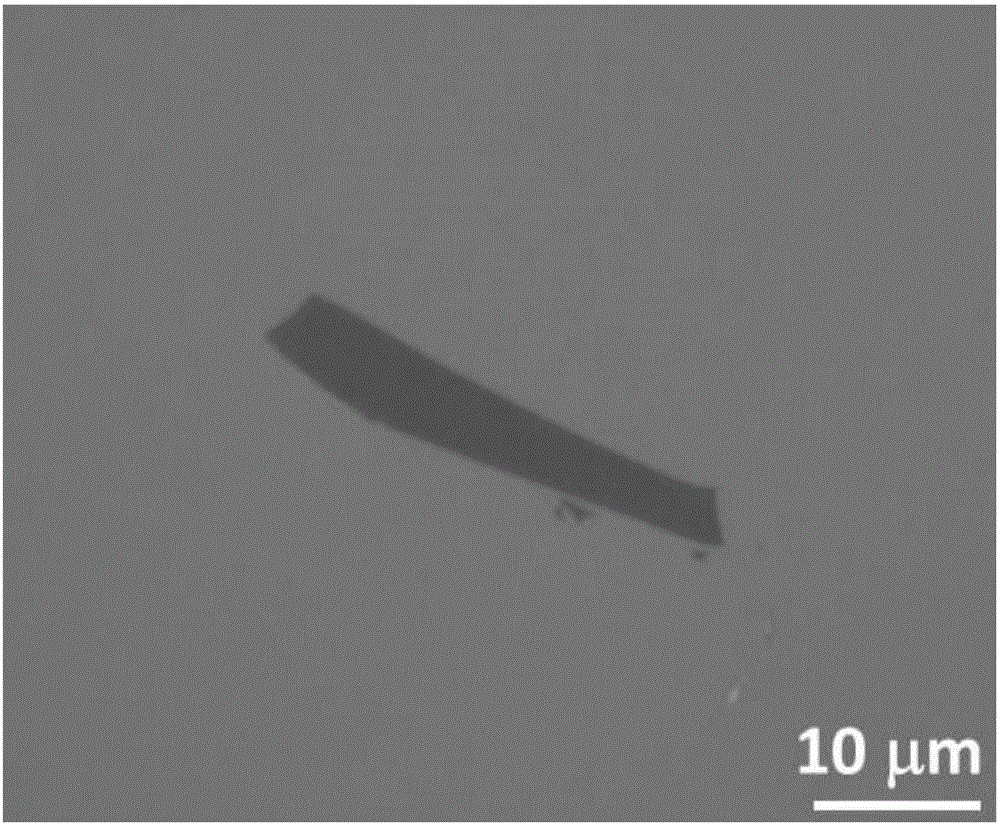

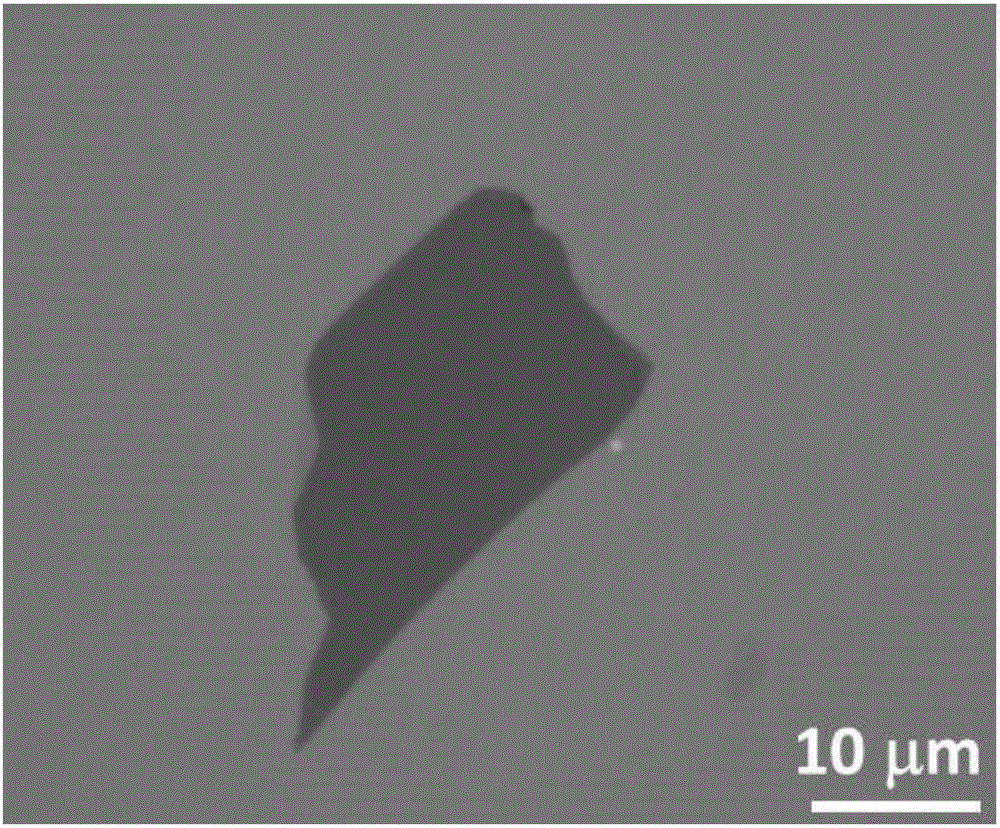

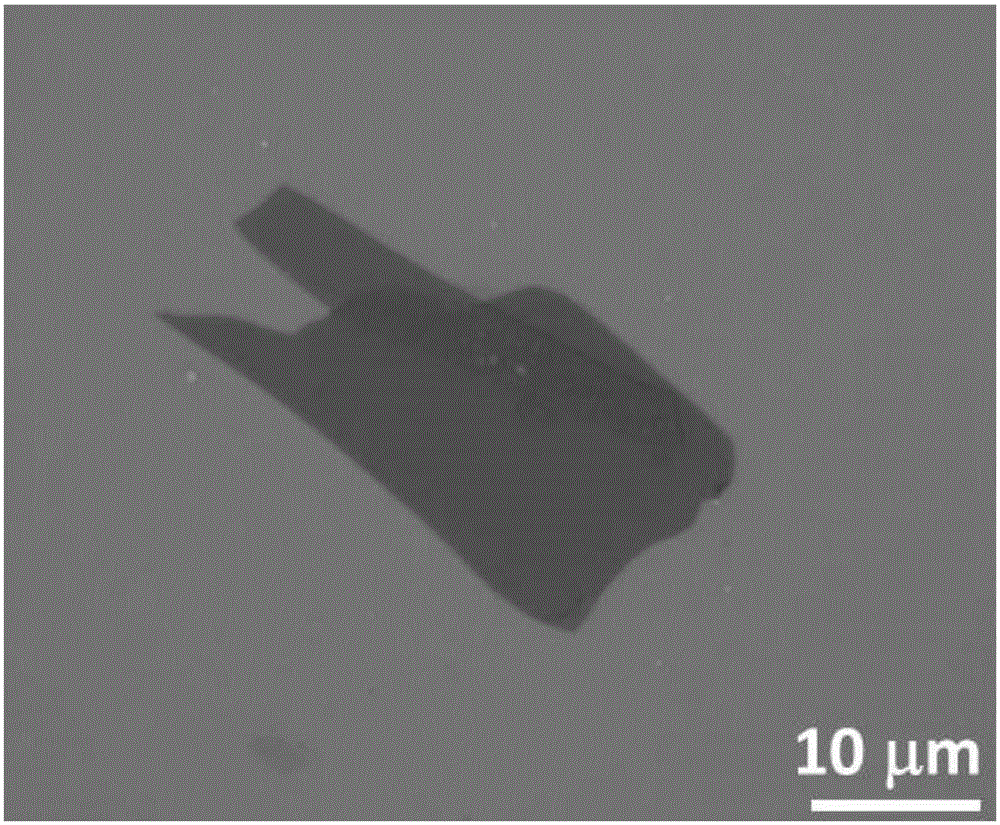

[0025] Tungsten diselenide samples were prepared on modified silicon wafers by mechanical exfoliation, such as figure 1 Shown is a tungsten diselenide sample.

[0026] On the tungsten diselenide material on the silicon wafer, the dichloromethane solution of one deck polymethyl methacrylate is spin-coated, and the mass volume ratio of the dichloromethane solution of polymethyl methacrylate is 3%; Material variance adjustments.

[0027] Cover the film made of polydimethylsiloxane on the polymer film of polymethyl methacrylate formed by spin co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com