Method for regenerating rock wool waste mixture

A technology of rock wool waste and mixture, applied in grain processing, glass manufacturing equipment, manufacturing tools, etc., to achieve low melting temperature, increase cotton production efficiency, and save coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

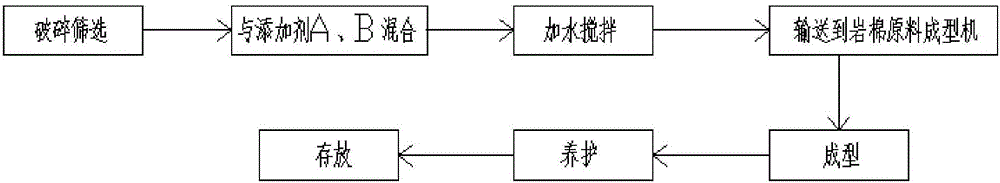

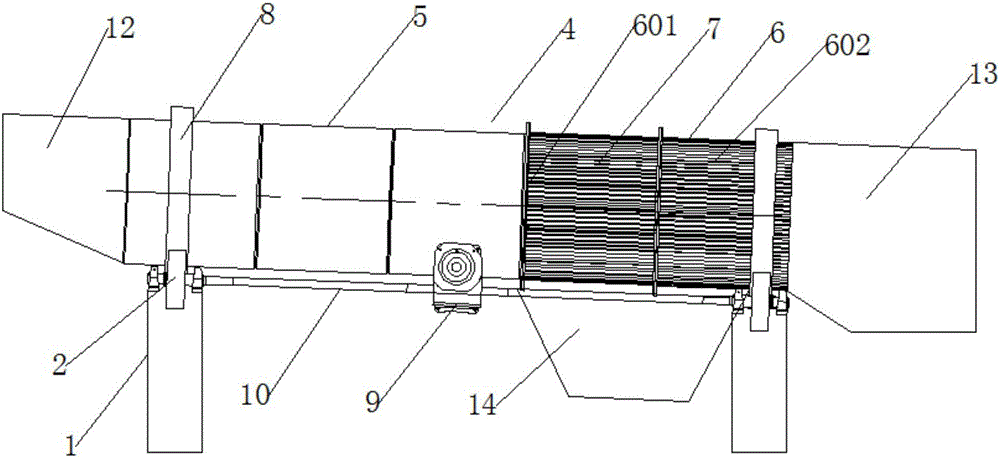

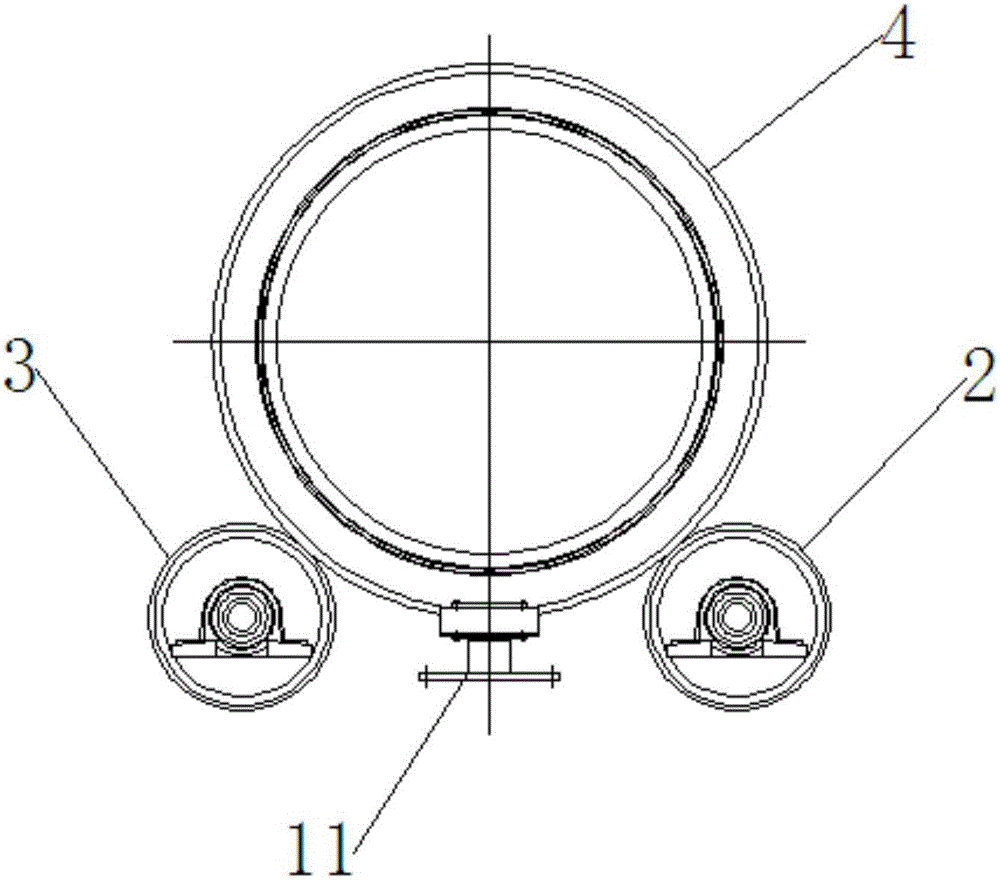

[0056] Put the rock wool waste into the rock wool waste crusher, screen out 80 parts by weight of the rock wool waste raw material with a particle size below 15 mm, get 6 parts by weight of the basalt waste with a particle size below 20 mm, and get 10 parts by weight of cement, Put it into the three warehouse batching machine for mixing and batching, put the mixed material into the mixer after mixing, add 4 parts by weight of water to form a uniformly stirred material, and then put it into the recycled rock wool raw material forming machine to form a cylinder Shaped regenerated rock wool raw materials are then transported to the curing shed, the curing temperature is 50°C, and the curing time is 8 hours. After the curing is completed, the regenerated rock wool raw materials are finally completed and transported to the warehouse for storage for use.

Embodiment 2

[0058] Put the rock wool waste into the rock wool waste crusher, screen out 70 parts by weight of the rock wool waste raw material with a particle size below 15mm, get 8 parts by weight of the basalt waste with a particle size below 20mm, and get 8 parts by weight of cement, Put it into the three warehouse batching machine for mixing and batching, put the mixed material into the mixer after mixing, add 6 parts by weight of water to form a uniformly stirred material, and then put it into the recycled rock wool raw material forming machine to form a cylinder Shaped regenerated rock wool raw materials are then transported to the curing shed, the curing temperature is 70°C, and the curing time is 6 hours. After the curing is completed, the regenerated rock wool raw materials are finally completed and transported to the warehouse for storage for use.

Embodiment 3

[0060] Put the rock wool waste into the rock wool waste crusher, screen out 90 parts by weight of rock wool waste raw materials with a particle size below 15mm, get 4 parts by weight of basalt waste with a particle size below 20mm, and get 12 parts by weight of cement, Put it into the three warehouse batching machine for mixing ingredients, put the mixed material into the mixer after mixing, add 2 parts by weight of water to form a uniformly stirred material, and then put it into the recycled rock wool raw material molding machine to form a rectangular parallelepiped shape The regenerated rock wool raw material is then transported to the curing shed, the curing temperature is 40°C, and the curing time is 10 hours. After the curing is completed, the regenerated rock wool raw material is finally completed and transported to the warehouse for storage for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com