Process for preparing methanol from carbon dioxide based on low-temperature plasma hydrogenation method

A low-temperature plasma and carbon dioxide technology, which is used in the preparation of hydroxyl compounds, the preparation of organic compounds, and the chemical industry to achieve the effects of mild reaction conditions, promotion of conversion, and low equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

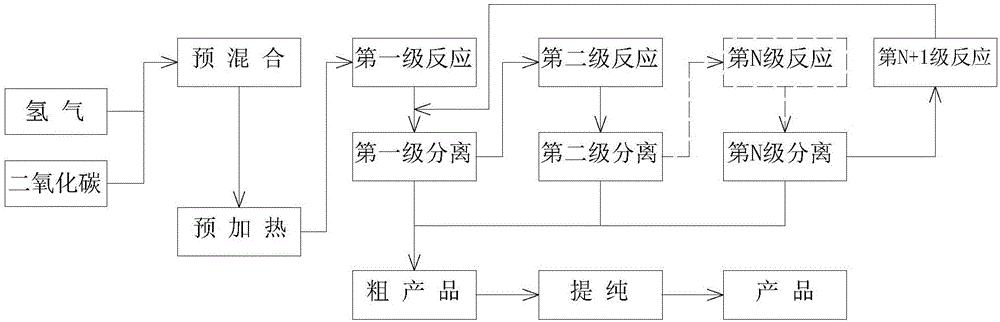

[0042] Embodiment 1, with reference to figure 1 , the process method for preparing methanol by low-temperature plasma hydrogenation of carbon dioxide, comprising the following steps:

[0043] 1) Pre-mixing: The feed molar ratio of carbon dioxide and hydrogen is 1:3, the ratio is adjusted through a mass flow meter, and hydrogen and carbon dioxide enter the pre-mixer through the delivery pipeline for pre-mixing;

[0044] 2) Preheating: heat the raw material gas premixed in step 1) in the preheater, and the heating temperature is 15°C;

[0045] 3) First-stage reaction: The preheated raw material gas is introduced into the first-stage DBD integrated reactor through the delivery pipeline for the first-stage reaction;

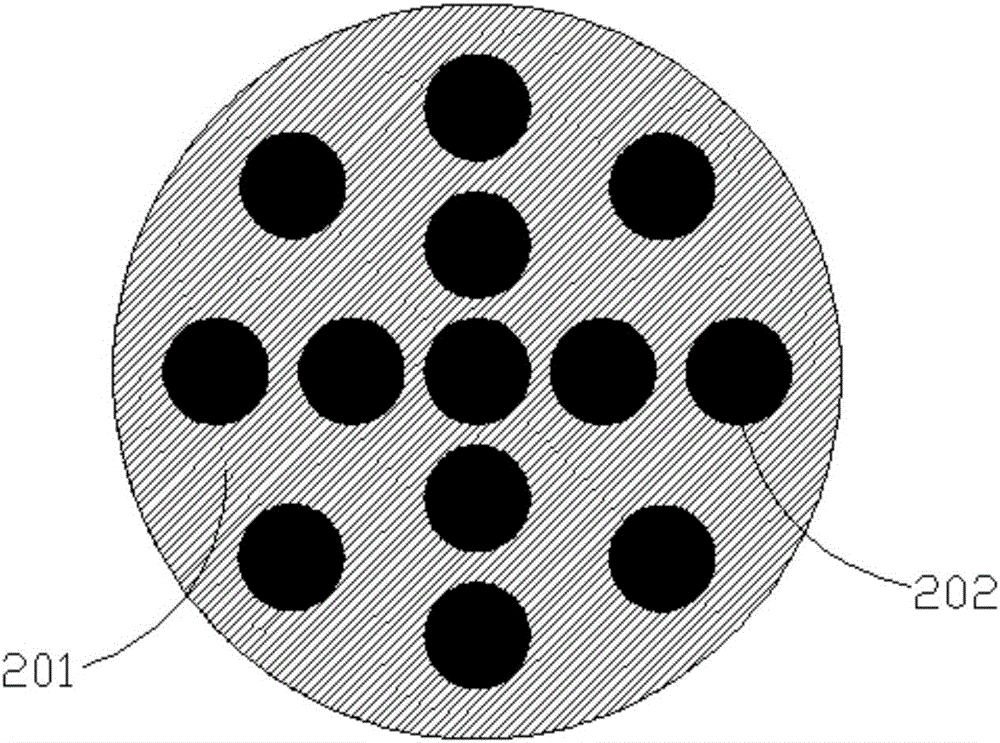

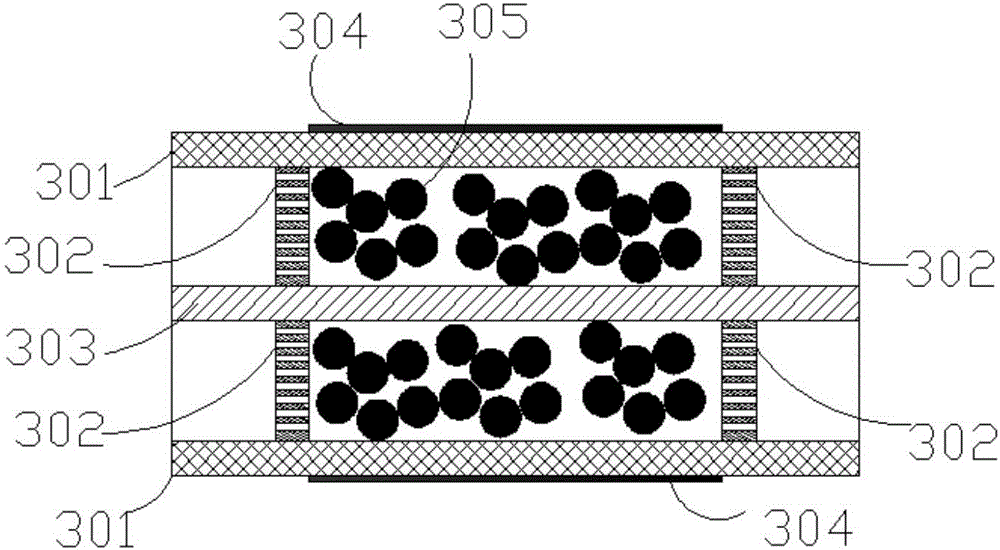

[0046] with TiO 2 , CdS and CaTiO 3 As a catalyst, the particle size of the catalyst is 1.5-2.5mm, and the filling length is 80cm; the driving power is a sinusoidal AC power supply, the discharge frequency is 30kHz, the driving voltage is 10kV, the power is 100W, ...

Embodiment 2

[0061] Embodiment 2 is different from Embodiment 1 in that the process for preparing methanol by low-temperature plasma hydrogenation of carbon dioxide comprises the following steps:

[0062] 1) Pre-mixing: The feed molar ratio of carbon dioxide and hydrogen is 1:1, the ratio is adjusted through a mass flow meter, and hydrogen and carbon dioxide enter the pre-mixer through the delivery pipeline for pre-mixing;

[0063] 2) Preheating: heat the raw material gas premixed in step 1) in the preheater, and the heating temperature is 30°C;

[0064] 3) First-stage reaction: The preheated raw material gas is introduced into the first-stage DBD integrated reactor through the delivery pipeline for the first-stage reaction;

[0065] Take ZnO, WO 3 , SrTiO 3 As a catalyst, the particle size of the catalyst is 1.5-2.5mm, and the filling length is 80cm; the driving power is a sinusoidal AC power supply, the discharge frequency is 1MHz, the driving voltage is 50kV, the power is 500W, and th...

Embodiment 3

[0073] Embodiment 3 is different from Embodiment 1 in that the process for preparing methanol by low-temperature plasma hydrogenation of carbon dioxide comprises the following steps:

[0074] 1) Pre-mixing: The feed molar ratio of carbon dioxide and hydrogen is 1:10, and the ratio is adjusted through a mass flow meter. Hydrogen and carbon dioxide enter the pre-mixer through the delivery pipeline for pre-mixing;

[0075] 2) Preheating: heat the raw material gas premixed in step 1) in the preheater, and the heating temperature is 50°C;

[0076] 3) First-stage reaction: The preheated raw material gas is introduced into the first-stage DBD integrated reactor through the delivery pipeline for the first-stage reaction;

[0077] with TiO 2 , Fe 2 o 3 , BaTiO 3 As a catalyst, the particle size of the catalyst is 1.5-2.5mm, and the filling length is 80cm; the driving power is a sinusoidal AC power supply, the discharge frequency is 500Hz, the driving voltage is 5kV, the power is 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com