A kind of degreasing agent for binary composite flooding sewage containing heterocyclic quaternary ammonium salt and its preparation method

A binary compound flooding, quaternary ammonium salt technology, applied in the direction of flocculation/sedimentation water/sewage treatment, organic chemistry, etc. Satisfy environmental protection, simple synthesis process, and promote the effect of increasing flocculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Degreaser P 1 and its preparation method

[0032] (1) Degreaser P 1 The composition, components and molecular formula are as follows:

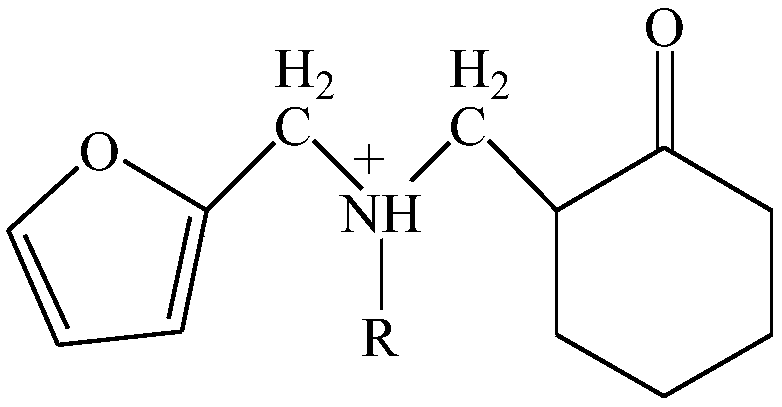

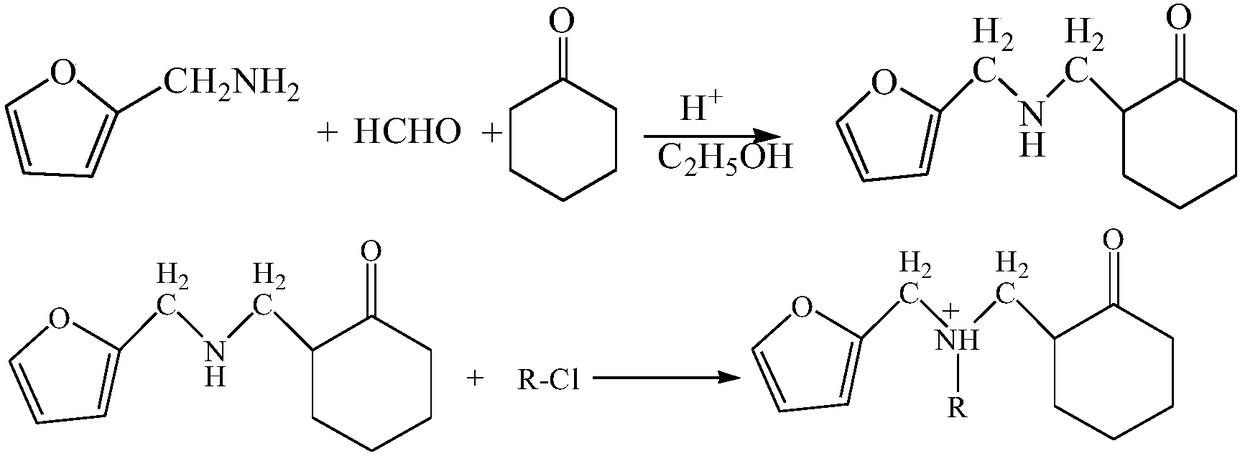

[0033] Degreaser P 1 It is obtained by reacting 2-furylmethylamine, formaldehyde, cyclohexanone and chloroalkane according to the molar ratio of 1:5:1.5:3.0. The molecular formula is as follows:

[0034]

[0035] where R is C 12 straight-chain alkanes.

[0036] (2) Degreaser P 1 The preparation method is as follows:

[0037] ①Add 1 mol of 2-furylmethylamine to a three-necked flask equipped with an electric stirrer, reflux condenser, and thermometer, then add 15 mol of ethanol as a solvent, heat up to 50°C, stir for 20 minutes at a stirring rate of 250 rpm, and then add 1.5 mol of For cyclohexanone, the temperature was raised to 70° C., the stirring rate was 300 rpm, the temperature was lowered to 30° C. after continuous stirring for 20 minutes, and then the pH value was adjusted to 3 with 15% hydrochloric acid to...

Embodiment 2

[0041] Embodiment 2: Degreaser P 2 and its preparation method

[0042] (1) Degreaser P 2 The composition, components and molecular formula are as follows:

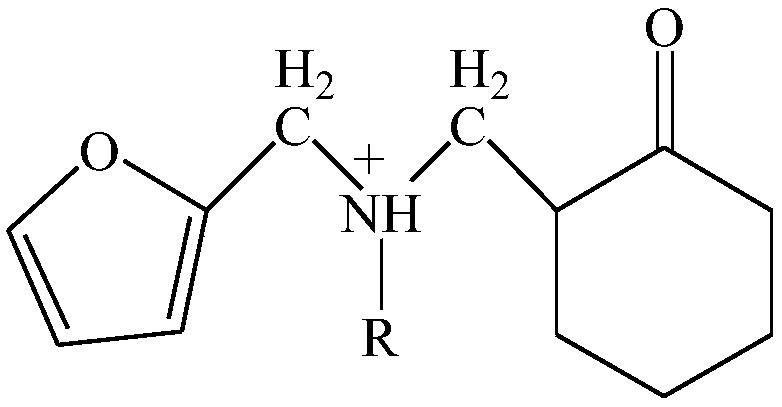

[0043] Degreaser P 2 It is obtained by reacting 2-furylmethylamine, formaldehyde, cyclohexanone and chloroalkane according to the molar ratio of 1:6:1.6:4. The molecular formula is as follows:

[0044]

[0045] where R is C 14 straight-chain alkanes.

[0046] (2) Degreaser P 2 The preparation method is as follows:

[0047]①Add 1mol of 2-furylmethylamine to a three-necked flask equipped with an electric stirrer, reflux condenser and thermometer, then add 12mol of ethanol as a solvent, heat up to 40°C, stir for 10min at a stirring rate of 200rpm, and then add 1.6mol For cyclohexanone, the temperature was raised to 60° C., the stirring rate was 400 rpm, the temperature was lowered to 35° C. after continuous stirring for 25 minutes, and then the pH value was adjusted to 2 with 15% hydrochloric acid to obtain a mixtur...

Embodiment 3

[0051] Embodiment 3: Degreaser P 3 and its preparation method

[0052] (1) Degreaser P 3 The composition, components and molecular formula are as follows:

[0053] Degreaser P 3 It is obtained by reacting 2-furylmethylamine, formaldehyde, cyclohexanone and chloroalkane according to the molar ratio of 1:7:1.8:4.5. The molecular formula is as follows:

[0054]

[0055] where R is C 16 straight-chain alkanes.

[0056] (2) Degreaser P 3 The preparation method is as follows:

[0057] ①Add 1mol of 2-furylmethylamine to a three-necked flask equipped with an electric stirrer, reflux condenser and thermometer, then add 10mol of ethanol as a solvent, heat up to 45°C, stir for 30min at a stirring rate of 300rpm, and then add 1.8mol For cyclohexanone, the temperature was raised to 65° C., the stirring rate was 330 rpm, the temperature was lowered to 32° C. after continuous stirring for 30 minutes, and then the pH value was adjusted to 5 with 15% hydrochloric acid to obtain a mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com