Selective near-infrared light response shape memory polymer composite material and preparation method thereof

A near-infrared light-responsive, memory polymer technology, applied in chemical instruments and methods, compounds containing elements of Group 3/13 of the periodic table, and organic compounds of Group 3/13 without C-metal bonds, etc. Nanoparticles are expensive, complicated in preparation process, and cannot be widely used, so as to achieve the effect of promoting application, improving dispersibility, and improving photothermal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of rare earth organic complex comprises the following steps:

[0043] S1: Dissolve A mol of rare earth chloride in 10mL-10L ethanol to generate a rare earth chloride solution; if the carboxylic acid organic ligand is liquid at room temperature, directly use B mol of carboxylic acid organic ligand as the first reagent ; If the carboxylic acid organic ligand is not a liquid at room temperature, then B mol of the carboxylic acid organic ligand is dissolved in 10mL-10L ethanol to generate a carboxylic acid organic ligand solution and as the first reagent; if the conjugated The organic ligand is liquid at room temperature, then directly use C mol conjugated organic ligand as the second reagent; if the conjugated organic ligand is not liquid at room temperature, then dissolve C mol conjugated organic ligand in In 10mL-10L ethanol, a conjugated organic ligand solution is generated and used as the second reagent; the ranges of A, B and C are all 0.001 to ...

Embodiment 1

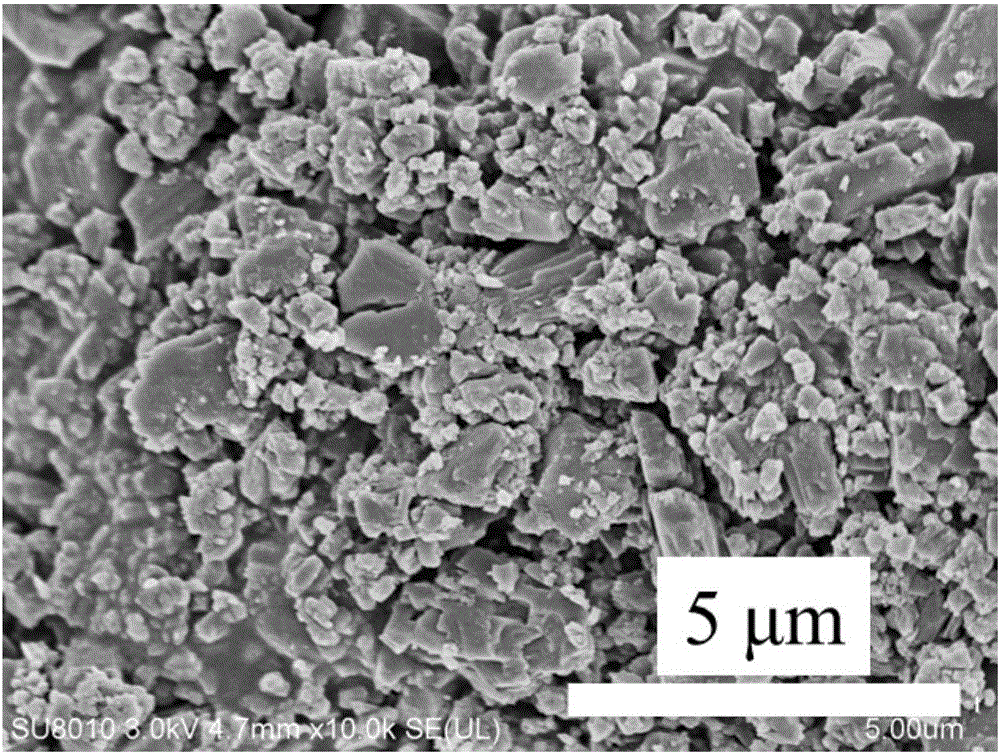

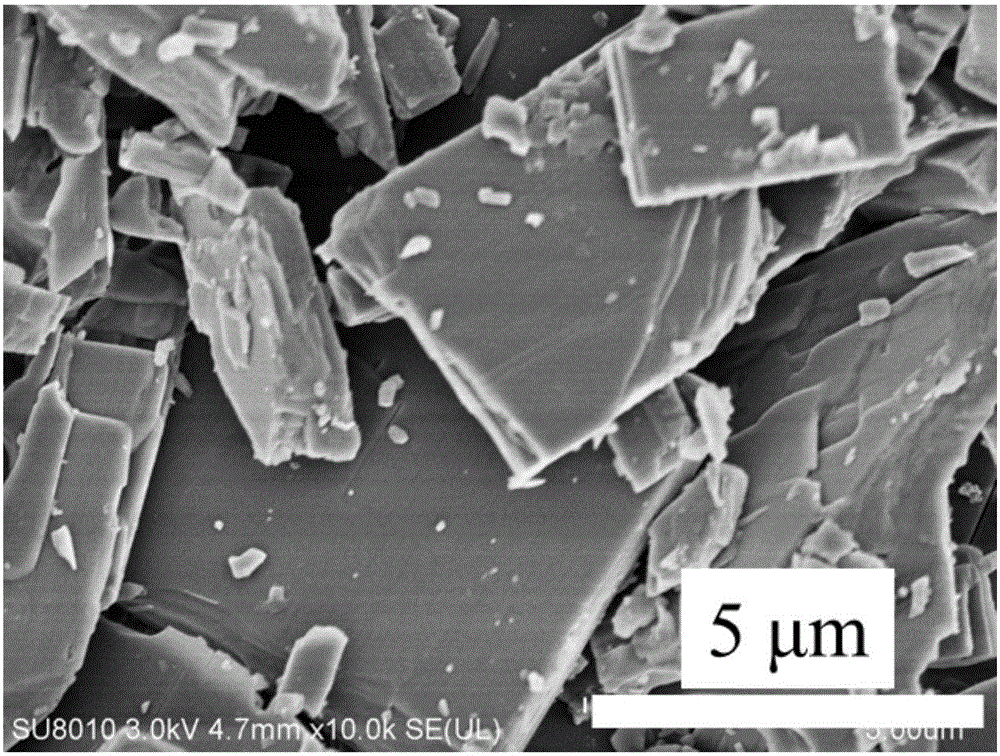

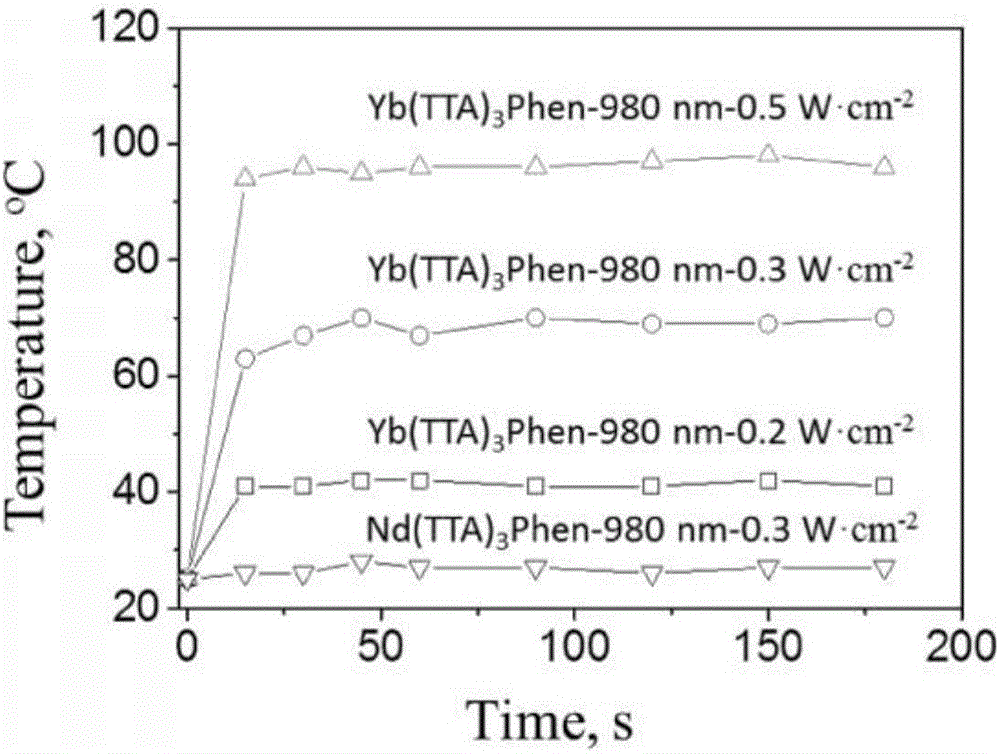

[0050] Embodiment 1 discloses rare earth ytterbium organic complex Yb (TTA) 3 Phen and Rare Earth Neodymium Organic Complex Nd(TTA) 3 Phen as RN 4 Preparation method of type-selective near-infrared photoresponsive photothermal filler. Among them, the rare earth ytterbium organic complex has selective absorption for 980nm near-infrared light; the rare earth neodymium organic complex has selective absorption for 808nm near-infrared light. Wherein, α-thienoyltrifluoroacetone (TTA) and 1,10-phenanthroline (phen) are used as conjugated organic ligands N, n=4; carboxylic acid organic ligands M are not used.

[0051] Embodiment 1 discloses Yb(TTA) 3 The preparation method of Phen comprises the following steps:

[0052] S1.11: Add 10mmol YbCl 3 ·6H 2 O is dissolved in 30mL ethanol to generate YbCl 3 solution; dissolve 30mmol α-thienoyl trifluoroacetone in 50mL ethanol to generate α-thienoyl trifluoroacetone solution; dissolve 10mmol 1,10-phenanthroline in 30mL ethanol to genera...

Embodiment 2

[0065] Embodiment 2 discloses rare earth ytterbium organic complex Yb (TTA) 3 Phen and Rare Earth Neodymium Organic Complex Nd(TTA) 3 Phen as RN 4 Preparation method of type-selective near-infrared photoresponsive photothermal filler. Among them, the rare earth ytterbium organic complex has selective absorption for 980nm near-infrared light; the rare earth neodymium organic complex has selective absorption for 808nm near-infrared light. Wherein, α-thienoyltrifluoroacetone (TTA) and 1,10-phenanthroline (phen) are used as conjugated organic ligands N, n=4; carboxylic acid organic ligands M are not used.

[0066] Embodiment 2 discloses Yb(TTA) 3 The preparation method of Phen comprises the following steps:

[0067] S2.11: Add 10mmol YbCl 3 ·6H 2 O is dissolved in 30mL ethanol to generate YbCl 3 solution; dissolve 30mmol α-thienoyl trifluoroacetone in 50mL ethanol to generate α-thienoyl trifluoroacetone solution; dissolve 10mmol 1,10-phenanthroline in 30mL ethanol to genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com