Mn (IV)-activated red hexafluoride light-emitting material and preparation method

A hexafluoride, red luminescence technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of high color temperature and low color rendering index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 0.202 g and HfO 2 Dissolve in 5ml hydrofluoric acid (40wt%), stir at room temperature for 60 minutes until the dissolution is complete, add 0.062g potassium hexafluoromanganate to this solution for 30 minutes; then add 0.304g cesium fluoride solid and continue to stir for 50 minutes. The obtained precipitate was washed 3 times with anhydrous acetic acid and anhydrous methanol, and finally dried in a vacuum drying oven for 24 hours. The orange-red powder obtained was the final product Cs 2 HfF 6 :Mn 4+ .

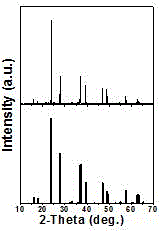

[0017] The XRD diffraction pattern of this phosphor is attached figure 1 As shown, the diffraction peaks of the sample are compared with the standard card JCPDS 74-0175 (Cs 2 HfF 6 ) Are completely consistent, and no diffraction peaks of any impurity phase are observed, which indicates that the samples we synthesized have a single crystal phase.

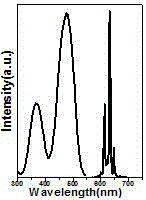

[0018] Attached figure 2 Shown are the room temperature excitation spectrum (monitoring wavelength is 631 nm) and emission...

Embodiment 2

[0022] Weigh 0.197 g and HfO 2 Dissolve in 10 ml of hydrofluoric acid (40wt%), stir for 30 minutes in a water bath at 50°C until the dissolution is complete, add 0.124g potassium hexafluoromanganate to this solution and react for 30 minutes; then add 0.456 g cesium fluoride solid Continue to stir for 60 min. The obtained precipitate was washed 3 times with anhydrous acetic acid and anhydrous methanol, and finally dried in a vacuum drying oven for 24 hours. The orange-red powder obtained was the final product Cs 2 HfF 6 :Mn 4+ .

Embodiment 3

[0024] Weigh 0.202 g and HfO 2 Dissolve in 10 ml of hydrofluoric acid (40wt%), stir for 10 minutes in a water bath at 80°C until the dissolution is complete, add 0.062g potassium hexafluoromanganate to this solution and react for 30 minutes; then add 0.608 g cesium fluoride solid Continue to stir for 60 min. The obtained precipitate was washed 3 times with anhydrous acetic acid and anhydrous methanol, and finally dried in a vacuum drying oven for 24 hours. The orange-red powder obtained was the final product Cs 2 HfF 6 :Mn 4+ .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com