Heat treatment process for regulating controlling yield strength ratio of medium manganese steel

A technology of yield ratio and process, which is applied in the field of heat treatment of plate products, can solve the problems that the stress concentration is difficult to be released, the plasticity of the steel has not been significantly improved, and the plasticity has no contribution, so as to achieve the effect of improving the earthquake resistance level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

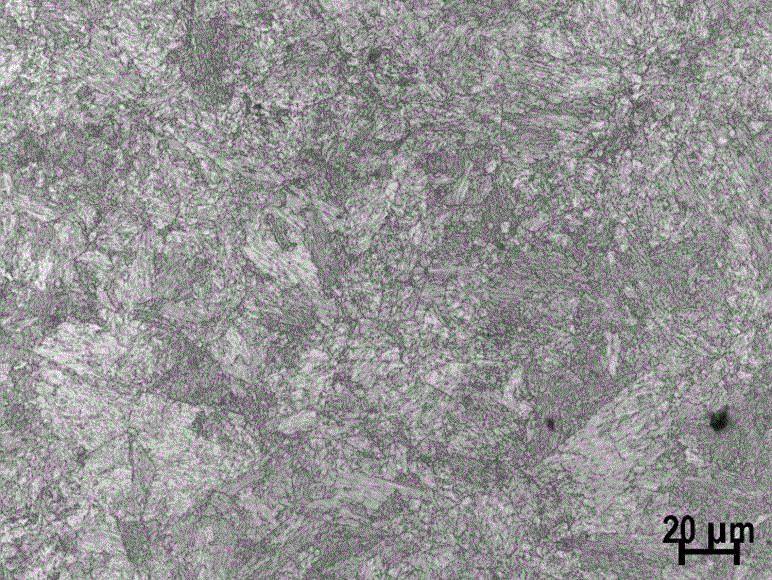

[0024] Medium manganese steel with a thickness of 60mm, the mass percentage of manganese content is 5.5%, figure 1 It is an optical micrograph of the metallographic structure of the medium manganese steel in Example 1, and the metallographic structure is tempered martensite + a small amount of reverse transformed austenite (M / A island) multiphase structure. The yield strength is 710MPa, the yield strength ratio is 0.93, the elongation is 19%, and the transverse impact energy absorbed by the Charpy impact test at -60°C is 127J, 133J, and 122J.

[0025] The above-mentioned medium manganese steel heat treatment process is carried out according to the following steps:

[0026] Quenching: Put a 60mm thick steel plate into a continuous heat treatment furnace, heat it at 850°C, keep it warm for 100 minutes, and cool it to room temperature after it comes out of the furnace, and control the cooling rate at 3°C / s-15°C / s;

[0027] Tempering: Put a 60mm thick steel plate into a continuou...

Embodiment 2

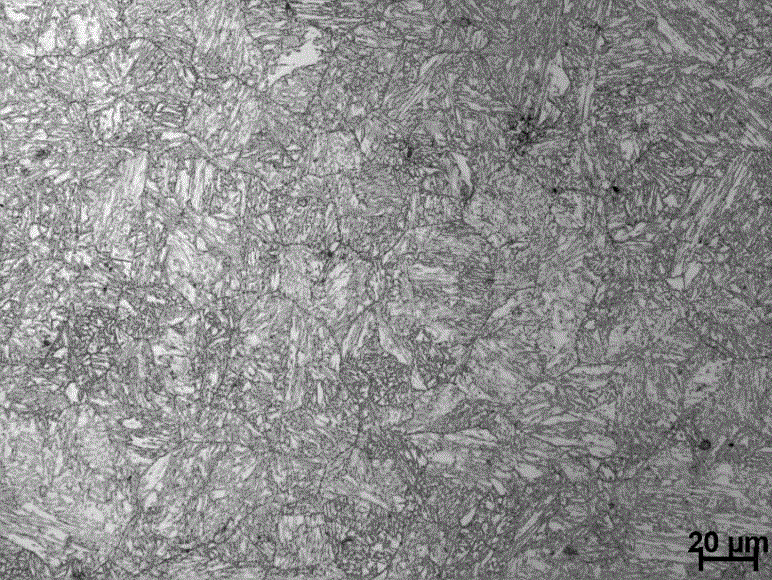

[0029] Medium manganese steel with a thickness of 40mm, the mass percentage of manganese content is 5.1%, figure 2 It is an optical micrograph of the metallographic structure of the medium manganese steel in Example 2, and the metallographic structure is tempered martensite + a small amount of reverse transformed austenite structure (M / A island) + a small amount of secondary martensite multiphase structure . The yield strength is 660MPa, the yield strength ratio is 0.82, the elongation is 24%, and the transverse impact energy absorbed by the Charpy impact test at -60°C is 154J, 149J, and 163J.

[0030] The above-mentioned medium manganese steel heat treatment process is carried out according to the following steps:

[0031] Quenching: Put a 40mm thick steel plate into a continuous heat treatment furnace, heat at 840°C, keep it warm for 110 minutes, and cool it to room temperature after being out of the furnace, and control the cooling rate at 3°C / s-15°C / s;

[0032] Temperin...

Embodiment 3

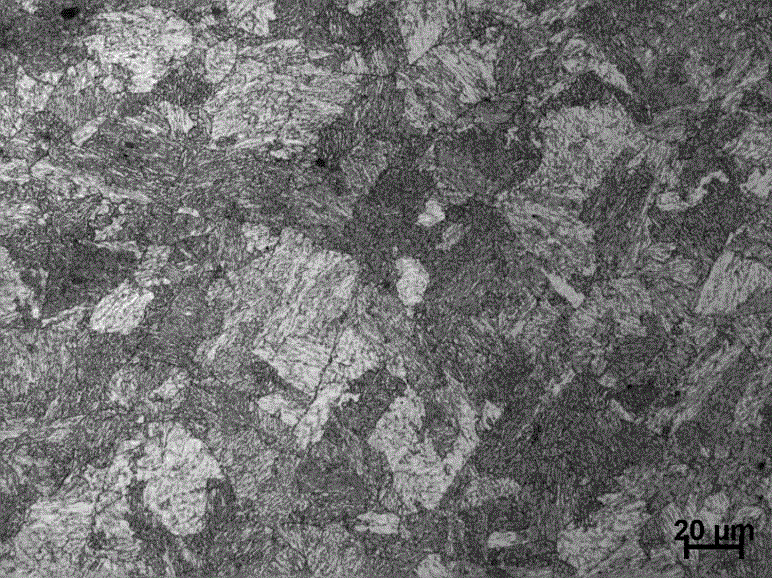

[0034] Medium manganese steel with a thickness of 30mm, the mass percentage of manganese content is 4.8%, image 3 It is an optical micrograph of the metallographic structure of the medium manganese steel in Example 3, and the metallographic structure is tempered martensite + reverse transformed austenite structure (M / A island) + secondary martensite multiphase structure. The yield strength is 560MPa, the yield strength ratio is 0.65, the elongation is 32%, and the transverse impact energy absorbed by the Charpy impact test at -60°C is 226J, 218J, and 233J.

[0035] The above-mentioned medium manganese steel heat treatment process is carried out according to the following steps:

[0036] Quenching: Put a 30mm thick steel plate into a continuous heat treatment furnace at a heating temperature of 830°C and keep it warm for 110 minutes. After leaving the furnace, it is water-cooled to room temperature, and the cooling rate is controlled at 3°C / s-15°C / s;

[0037] Tempering: Put a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com