A preparation method for obtaining complex precision fine-grained castings

A precise and fine-grained technology, which is applied in the field of obtaining complex precision and fine-grained castings, can solve the problems of coarse structure and incomplete filling of castings, and achieve the effects of less structure defects, improved production efficiency and high density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

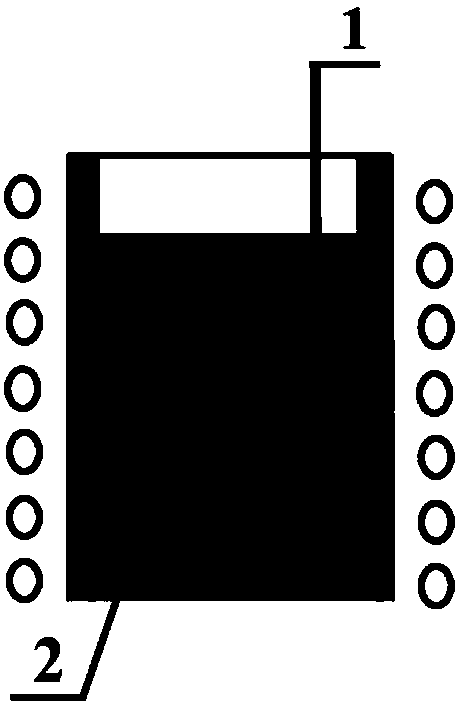

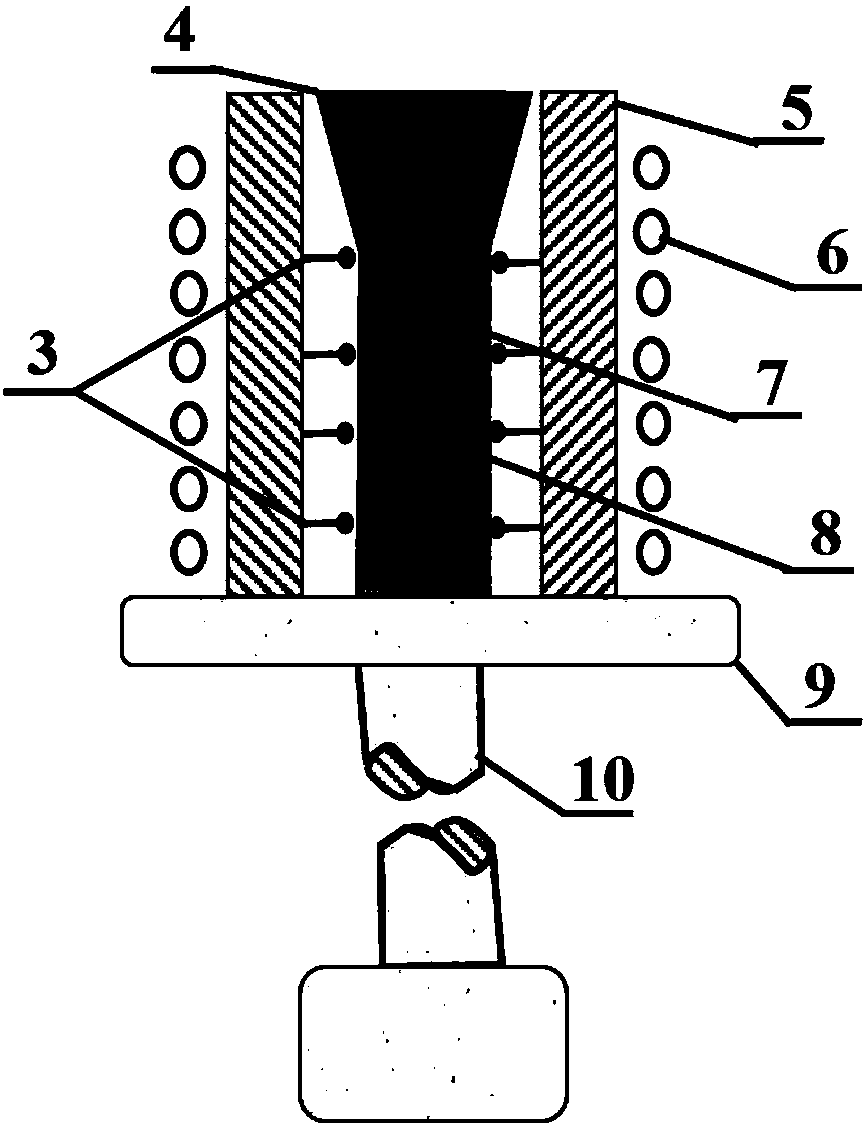

[0053] Realize the device of preparation method of the present invention such as Figure 1a and 1b As shown, it includes a platinum-rhodium thermocouple 1 , a fixing fixture 3 , a sprue cup 4 , a support platform 5 , an induction coil 6 , a mold shell 7 , a water-cooled copper plate 9 and a rotating screw 10 .

[0054] Figure 2a and Figure 2b In order to use this process to pour out the physical map of precision fine-grained castings, the grain size of the target sample in the precision castings should reach ASTM2-3 (such as Figure 3a , Figure 3b shown).

[0055] Such as Figure 5 As shown, a preparation method for obtaining complex precision fine-grained castings comprises the following steps:

[0056] (1), melt superheating treatment

[0057] (11) First put the nickel-based superalloy Ni-22Cr-18W-1Mo (indicating that the mass ratio of Ni:Cr:W:Mo in the alloy is 1:22:18:1) into the quartz crucible, and put the quartz crucible into the vacuum arc melting furnace, an...

specific Embodiment 2

[0071] A preparation method for obtaining complex precision fine-grained castings, comprising the following steps:

[0072] (1), melt superheating treatment

[0073] (11) First put the nickel-based superalloy Ni-22Cr-18W-1Mo into the quartz crucible, and put the quartz crucible into the vacuum arc melting furnace, then vacuumize it, and in a vacuum of 10 -2 Pass inert gas at Pa,

[0074] (12) When the furnace pressure exceeds 0.5Pa, heat the nickel-based superalloy Ni-22Cr-18W-1Mo to 1500°C through a medium-frequency electromagnetic field, and obtain a melt after holding for 10 minutes;

[0075] (2) slow cooling

[0076] The melt obtained in step (1) is cooled to 1410° C., and the cooling rate is 2° C. / min, wherein:

[0077] During the cooling process, the temperature of the melt obtained in step (1) is measured by multiple platinum-rhodium thermocouples, and the maximum temperature difference measured by each platinum-rhodium thermocouple is no more than 3°C.

[0078] (3)...

specific Embodiment 3

[0087] A preparation method for obtaining complex precision fine-grained castings, comprising the following steps:

[0088] (1), melt superheating treatment

[0089] (11) First put the nickel-based superalloy Ni-22Cr-18W-1Mo into the quartz crucible, and put the quartz crucible into the vacuum arc melting furnace, then vacuumize, and in the vacuum degree of 5 × 10 -3 Pass inert gas at Pa,

[0090] (12) When the furnace pressure exceeds 0.5Pa, heat the nickel-based superalloy Ni-22Cr-18W-1Mo to 1475°C through an intermediate frequency electromagnetic field, and obtain a melt after holding for 15 minutes;

[0091] (2) slow cooling

[0092] The melt obtained in step (1) is cooled to 1410° C., and the cooling rate is 1.6° C. / min, wherein:

[0093] During the cooling process, the temperature of the melt obtained in step (1) is measured by multiple platinum-rhodium thermocouples, and the maximum temperature difference measured by each platinum-rhodium thermocouple is no more than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com