Gas shielded welding wire, gas shielded welding wire steel wire rod and production method of gas shielded welding wire steel wire rod

A technology of gas shielding and production methods, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve problems such as poor forming performance and uneven weld bead, and achieve fast solidification, uniform and smooth weld surface, Bead forming beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

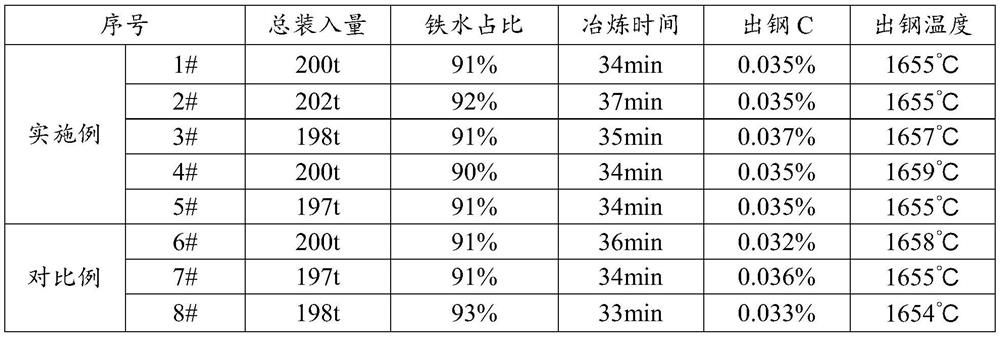

[0035] An embodiment of the present invention provides a gas shielded welding wire steel wire rod, a gas shielded welding wire and a production method of the gas shielded welding wire steel wire rod.

[0036] The gas shielded welding wire steel wire rod of the present invention, its chemical composition includes: C0.03~0.08%, Si 0.5~1.0%, Mn 1.4~1.8%, S 0.013~0.1%, P≤0.0015%, Ni≤0.8%, Cr≤0.4%, Mo≤0.4%, the balance is Fe and unavoidable impurities; and, the mass percentage of C, Si, Mn, P, S satisfies: liquidus temperature T L =1537-88[C]-8[Si]-5[Mn]-30[P]-25[S], solidus temperature T S =1536-415[C]-12[Si]-6.8[Mn]-125[P]-184[S], 25℃≤T L -T S ≤45°C.

[0037] Among them, at the above-mentioned liquidus temperature T L , solidus temperature T S In the formula of , square brackets "[]" represent the mass percentage of the elements, for example [C] represents the mass percentage of C, and the other elements are analogous.

[0038] Preferably, the mass percentages of C, Mn, Ni,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com