High-strength anti-crack concrete and preparation process thereof

A concrete and high-strength technology, which is applied in the field of concrete, can solve the problems that recycled concrete cannot be bonded well, restricts the wide application of recycled aggregates, and the strength of recycled aggregates is not high, so as to reduce macro and micro defects and increase thickness. Larger, cracking and compressive strength-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-5

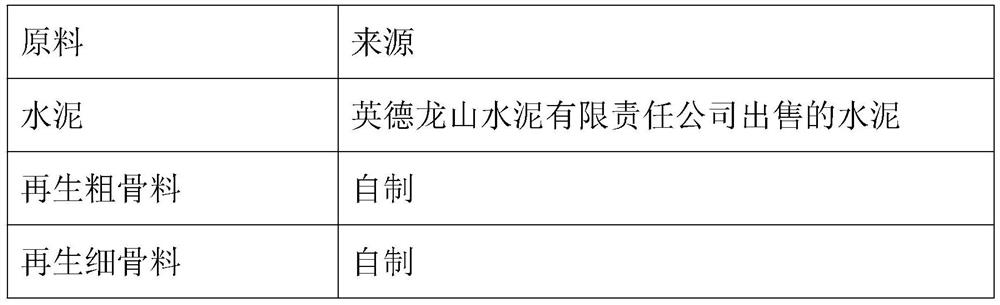

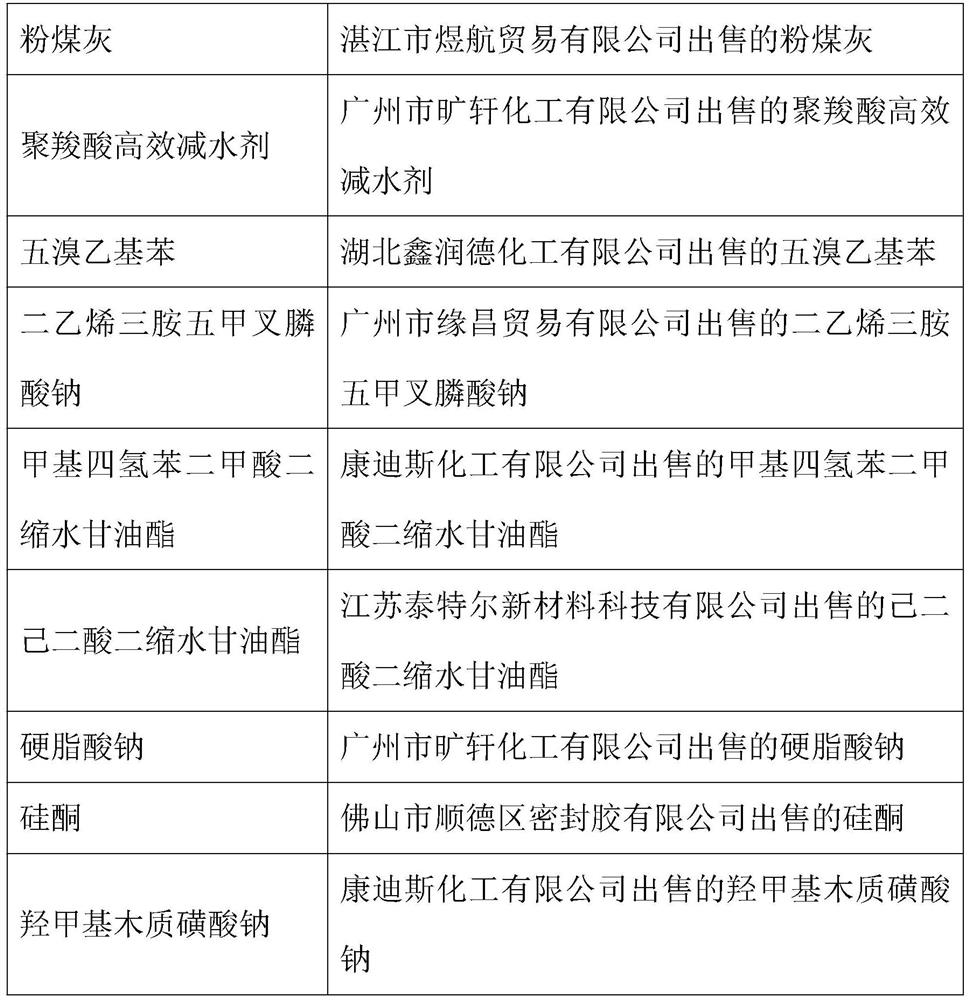

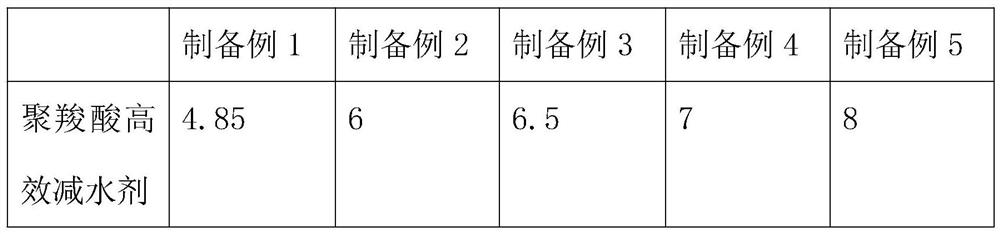

[0057] This preparation example discloses an admixture, including the preparation of components in parts by mass in Table 2, unit: Kg.

[0058] Table 2

[0059]

[0060]

[0061] The preparation method of the admixture is: add polycarboxylate high-efficiency water reducer, pentabromoethylbenzene, and sodium diethylenetriaminepentamethylene phosphonate together into a stirring tank, stir at a stirring speed of 300 rpm, and stir for 17 minutes to obtain admixture.

preparation example 6

[0063] The only difference with Preparation Example 4 is:

[0064] In the preparation method of the admixture: the stirring speed is 200 rpm, and the stirring is carried out for 15 minutes.

preparation example 7

[0066] The only difference with Preparation Example 4 is:

[0067] In the preparation method of the admixture: the stirring speed is 400 rpm, and the stirring is carried out for 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com