Punctiform needle-punching equipment and processing technique

A processing technology and acupuncture technology, applied in the field of point-shaped acupuncture equipment and processing technology, can solve the problems of pull-off, overall function failure, low peel strength, etc., and achieve the effect of minimal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and with reference to the data. It should be understood that the embodiments are only for illustrating the present invention and not limiting the scope of the present invention in any way.

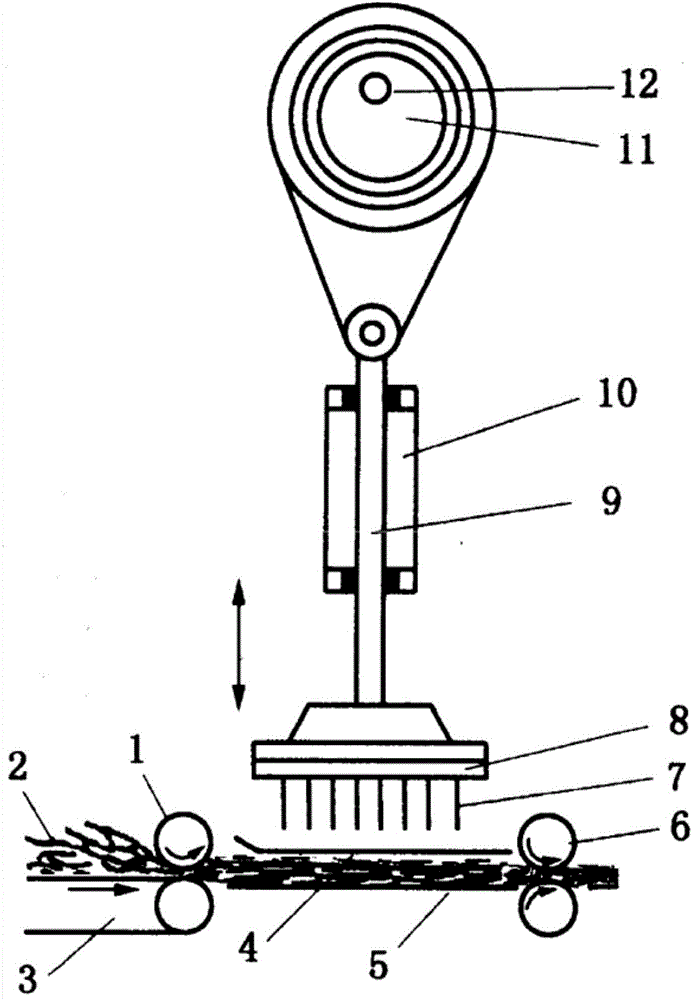

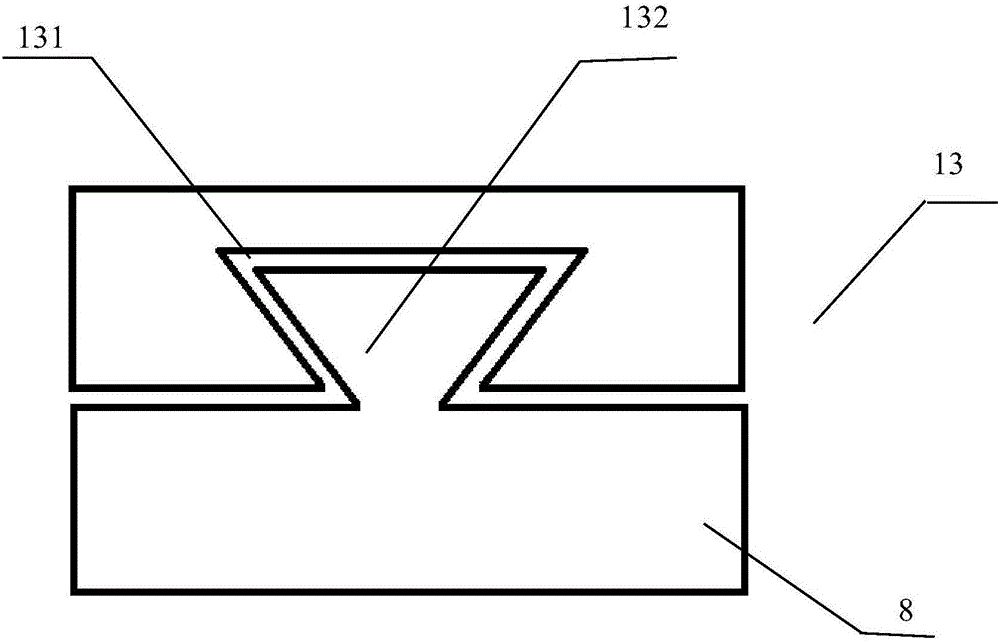

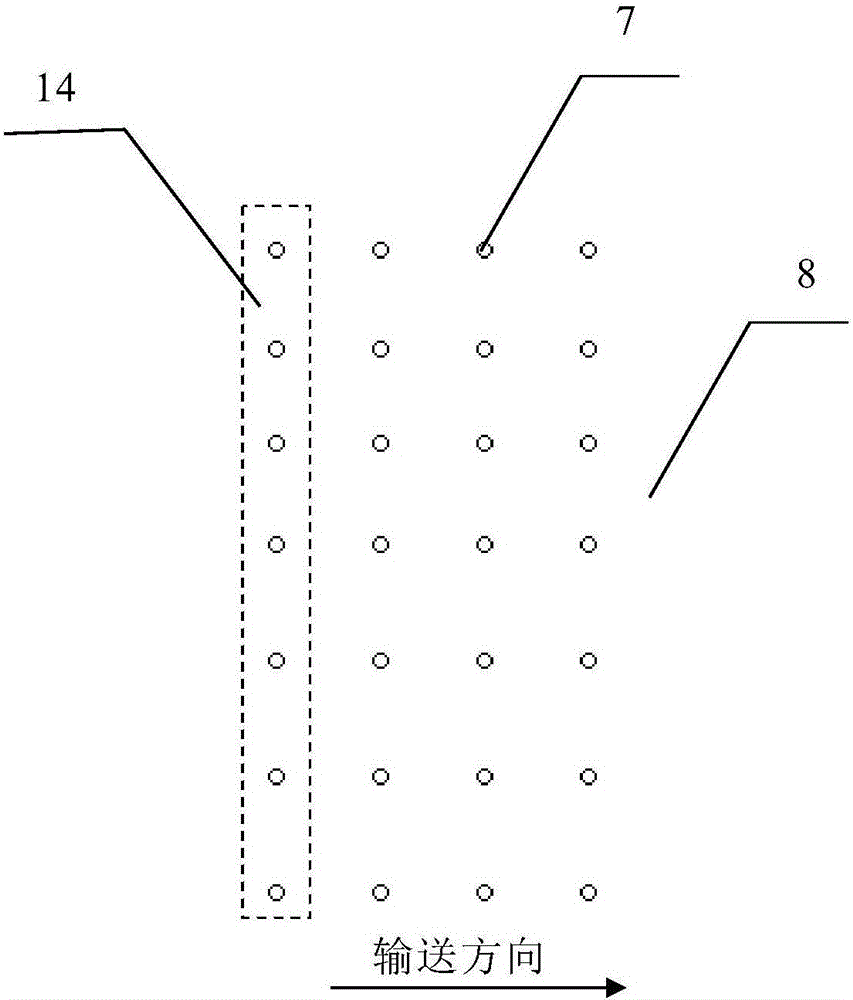

[0034] like Figure 1-3 As shown, the present invention discloses a point-shaped acupuncture device, which includes a conveying component, a supporting net mechanism, a point-shaped acupuncture mechanism and a control unit,

[0035] The conveying part is used to convey the fiber web to the needling area,

[0036] The support net mechanism is used to support the fiber web in the needling area,

[0037] The point acupuncture mechanism includes a needle bed assembly and a needle bed traversing assembly. The needle bed assembly is used for acupuncture on the fiber web. The needle bed assembly can drive the eccentric wheel through the rotation of the main shaft, and the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com