Softening agent of wig for dressing up and preparation method of softening agent

A softener and wig technology, applied in the field of wig softener for dress up and its preparation, can solve the problems of bad wig color, easy occurrence of knots, human injury, etc., to reduce damage, protect the luster of wigs, and reduce knots. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

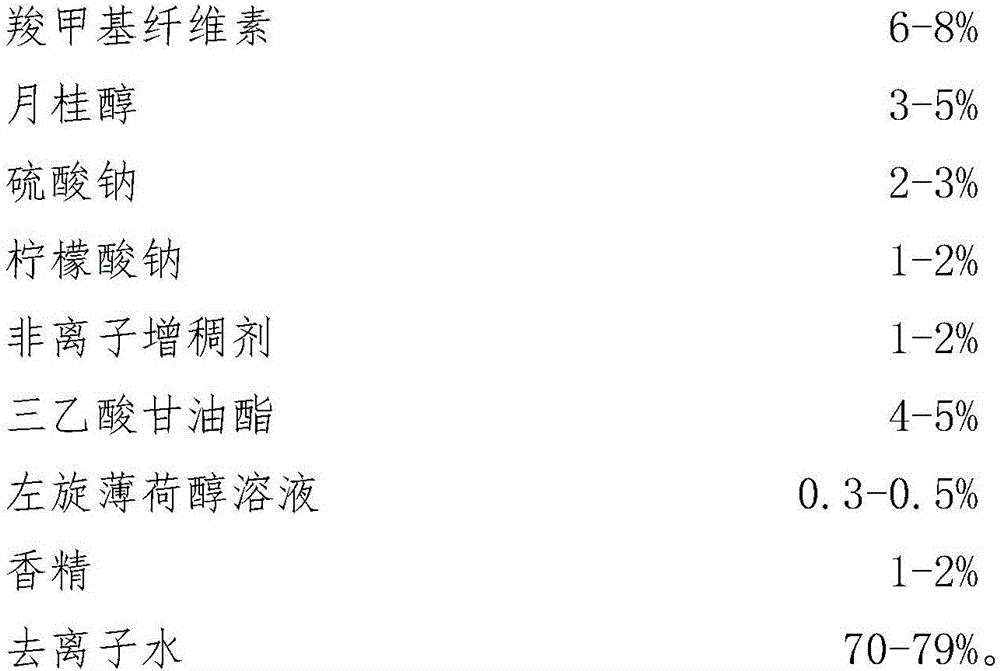

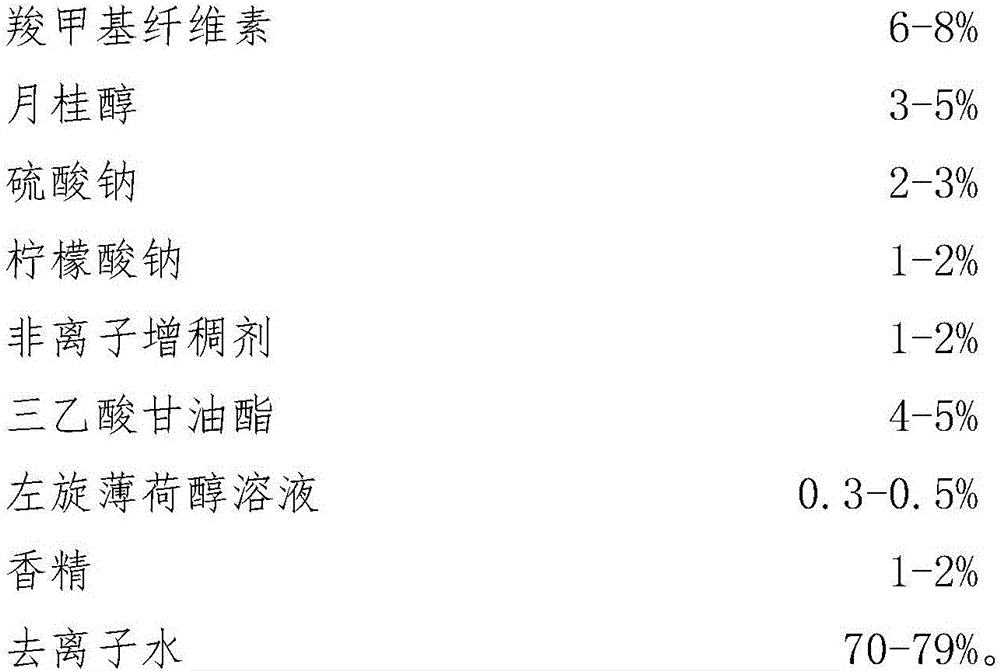

Image

Examples

Embodiment 1

[0020] (1) Get 6kg carboxymethylcellulose, 0.5kg 5% L-menthol solution, 2kg sodium citrate, 30kg deionized water and mix, stir for 10min to obtain solution 1;

[0021] (2) Mix 3kg lauryl alcohol, 2kg sodium sulfate, 5kg triacetin and 48.5kg deionized water, and stir for 10 minutes to obtain solution 2;

[0022] (3) Slowly add solution 2 to solution 1 in the above steps, and add 2kg PEG-fatty acid ester and 1kg lavender essence, after fully stirring, obtain a wig softener for dressing up.

Embodiment 2

[0024] (1) Get 8kg carboxymethylcellulose, 0.5kg 5% L-menthol solution, 2kg sodium citrate, 30kg deionized water and mix, stir for 10min to obtain solution 1;

[0025] (2) Mix 5kg lauryl alcohol, 2kg sodium sulfate, 5kg triacetin and 44.5kg deionized water, and stir for 10 minutes to obtain solution 2;

[0026] (3) Slowly add solution 2 to solution 1 in the above steps, and add 2kg PEG-fatty acid ester and 1kg lavender essence, after fully stirring, obtain a wig softener for dressing up.

Embodiment 3

[0028] (1) Get 6kg carboxymethylcellulose, 0.5kg 5% L-menthol solution, 1kg sodium citrate, 30kg deionized water and mix, stir for 10min to obtain solution 1;

[0029] (2) Mix 5kg lauryl alcohol, 2kg sodium sulfate, 4kg triacetin and 48.5kg deionized water, and stir for 10 minutes to obtain solution 2;

[0030] (3) Slowly add solution 2 to solution 1 in the above steps, and add 2kg PEG-fatty acid ester and 1kg lavender essence, after fully stirring, obtain a wig softener for dressing up.

[0031] The above-mentioned embodiment was tested with 3 commercially available wig softeners for softness, knotting, color and other properties. The specific results are shown in Table 1

[0032] Table 1

[0033] Test items Example 1 Example 2 Example 3 Softener 1 Softener 2 Softener 3 Softness excellent excellent excellent good excellent excellent Knot situation generally less less generally more generally color better it is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com