Method for reinforcing and deacidifying paper archives

A technology for paper archives and deacidification, which is used in the addition of anti-aging agents for paper, papermaking, textiles and papermaking, etc. It can solve the problems of the need for further improvement of the reinforcement effect and weak physical adhesion, so as to reduce the uneven deacidification. , Improve pH and mechanical strength, improve the effect of reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

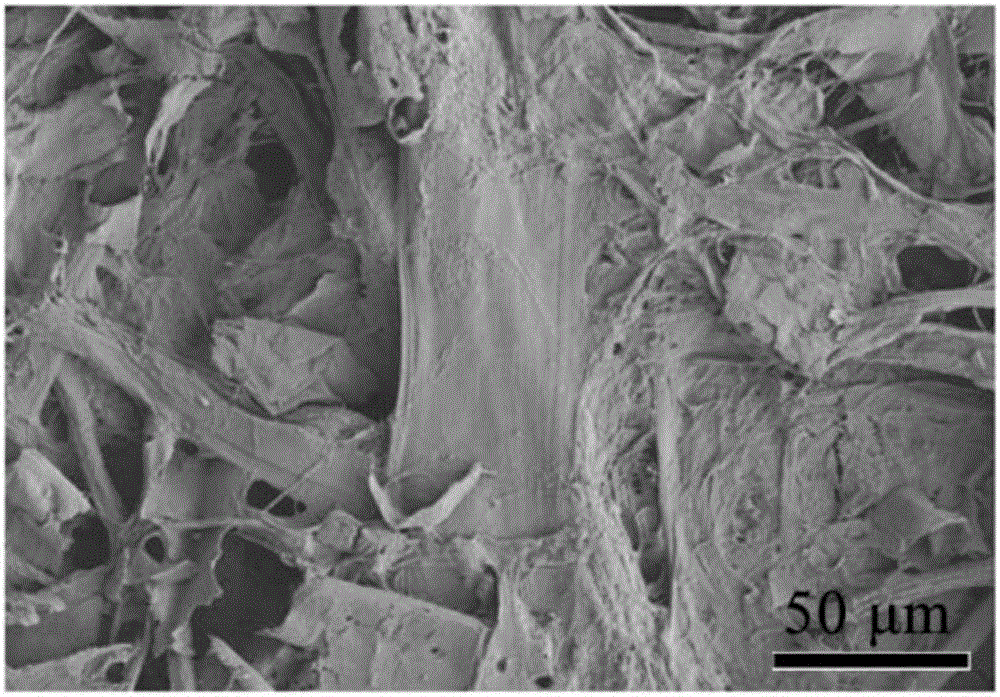

[0025] The papers in the archives of books and periodicals published by the People's Publishing House in 1966 are treated as objects. First, brush epichlorohydrin on the paper to make the paper completely wet, and then brush the hydroxypropyl methylcellulose-stabilized nano-magnesium hydroxide alcohol water dispersion, which is composed of hydroxypropyl methylcellulose aqueous solution and The nano-magnesium hydroxide ethanol dispersion is uniformly mixed at a volume ratio of 50:50, wherein the mass volume concentration of hydroxypropyl methylcellulose in the hydroxypropyl methylcellulose aqueous solution is 18.0g / L, and the nano-magnesium hydroxide ethanol The mass volume concentration of nano magnesium hydroxide in the dispersion liquid is 8.0g / L. Then the paper is dried in an oven at 50° C. for 1 hour to complete the strengthening and deacidification of the paper.

[0026] Untreated archival paper and reinforced deacidified archival paper are as follows: figure 1 and 2 A...

Embodiment 2

[0032]The papers in the book archive "Shi Fang Ge Kuo" published by the Commercial Printing House in 1905 were treated as objects. First, apply epichlorohydrin on the paper to make the paper completely wet, and then apply methyl cellulose-stabilized nano-calcium hydroxide alcohol aqueous dispersion, which is composed of methyl cellulose aqueous solution and nano-calcium hydroxide isopropyl The alcohol dispersion is uniformly mixed at a volume ratio of 40:60, wherein the mass volume concentration of methyl cellulose in the methyl cellulose aqueous solution is 20.0g / L, and the concentration of nano calcium hydroxide in the isopropanol dispersion of nano calcium hydroxide is The mass volume concentration is 8.0g / L. Then the paper is dried in an oven at 60° C. for 1 hour to complete the strengthening and deacidification of the paper. Table 2 shows the pH and mechanical properties of the paper samples before and after the reinforcement and deacidification treatment and after 10 da...

Embodiment 3

[0036] The papers in the book archive "Red Flag" published by People's Publishing House in 1979 were treated as objects. First, spray epichlorohydrin on the paper to make the paper completely wet, and then brush the hydroxyethyl cellulose-stabilized nano-barium hydroxide alcohol aqueous dispersion, which is composed of hydroxyethyl cellulose aqueous solution and nano-barium hydroxide ethanol The dispersion liquid is uniformly mixed according to the volume ratio of 50:50, wherein the mass volume concentration of hydroxyethyl fiber in the hydroxyethyl fiber aqueous solution is 19.0g / L, and the mass volume concentration of nano barium hydroxide in the ethanol dispersion of nano barium hydroxide The concentration is 7.5g / L. Then the paper is dried in an oven at 50° C. for 1 hour to complete the strengthening and deacidification of the paper. Table 3 shows the pH and mechanical properties of the samples before and after the paper sample was strengthened and deacidified and after 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass volume concentration | aaaaa | aaaaa |

| Mass volume concentration | aaaaa | aaaaa |

| Mass volume concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com