Hydrotreating method of high-acid high-calcium heavy crude oil

A heavy crude oil and hydrogenation treatment technology, which is applied in the fields of hydrogenation treatment process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of high operation risk, reduce equipment investment, improve calcium capacity, and realize effective utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

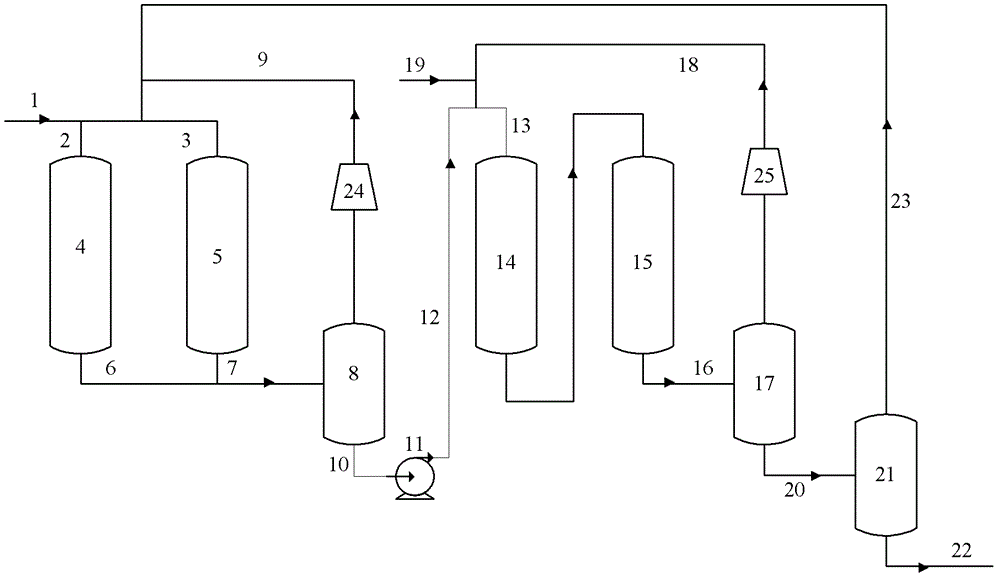

[0048] Crude oil A is mixed with the gas product separated by the low-pressure separator 21 of the high-pressure hydrotreating zone and the gas product separated by the high-pressure separator 8 of the low-pressure hydrotreating zone and compressed by the compressor 24, and then enters the low-pressure hydrotreating zone The hydrogenation protection reactor 4 is in contact with the hydrogenation protection catalyst under low pressure conditions to carry out the hydrogenation reaction, and the hydrogenation product is separated to obtain the first hydrogen-rich gas and the first liquid product, wherein the first hydrogen-rich gas passes through the compressor 24 returns to the entrance of the low-pressure hydroprocessing area after being compressed, and the first liquid product enters the high-pressure hydroprocessing area after being boosted by the pump 11, and is separated from fresh hydrogen and the high-pressure separator 17 from the high-pressure hydroprocessing area and pas...

Embodiment 2

[0052] Hydrotreating was carried out according to the method of Example 1. The difference was that the raw oil was crude oil B, and its properties were shown in Table 1.

Embodiment 3

[0054] Hydrotreating was carried out according to the method of Example 1. The difference was that the feedstock oil was crude oil C, and its properties were shown in Table 1.

[0055] Table 1

[0056]

Crude A

crude oil B

crude oil C

Density (20℃), g / cm 3

0.945

0.957

0.982

Carbon residue value, wt%

6.47

7.210

8.53

S, weight %

1.50

1.89

2.10

N, weight %

0.35

0.33

0.29

Total acid value, mgKOH / g

2.1

7.4

15.0

Metal content, ppm

Ni

18.6

31.6

10.5

V

1.3

1.9

50.1

Ca

350

500

1400

[0057] Table 2

[0058]

Example 1

Example 2

Example 3

Low pressure hydrotreating zone

Hydrogen partial pressure, MPa

2.0

5.0

3.0

Reaction temperature, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com