Casting and vibrating method and vibrating device during large-size concrete structure construction

A technology of large-volume concrete and concrete structures, which is applied in the direction of construction, building structure, and building material processing. It can solve problems such as structural safety hazards, formwork deformation, and low construction efficiency, so as to improve bearing capacity and crack resistance. Improve overall rigidity and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention is illustrated below through specific examples.

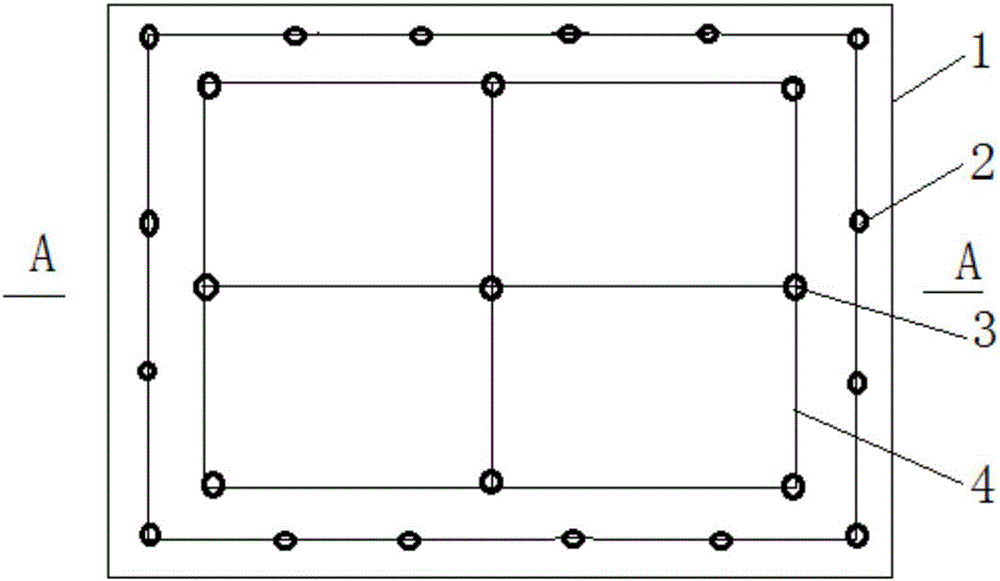

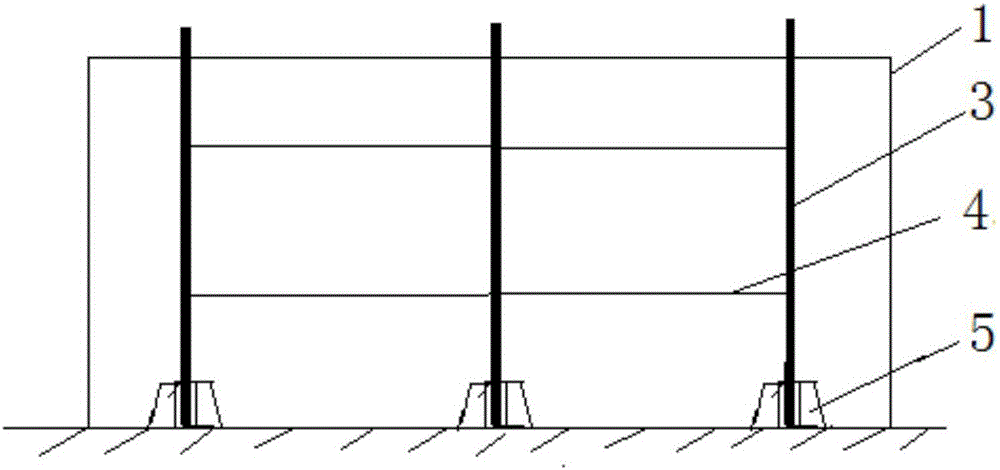

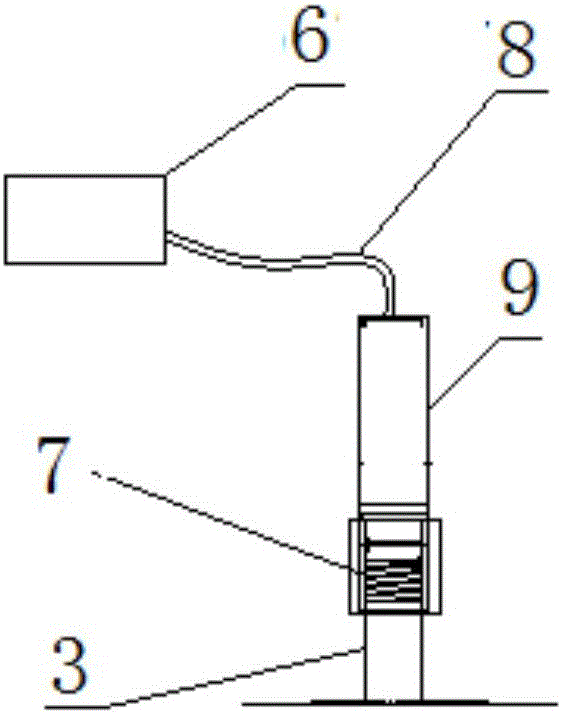

[0025] Such as figure 1 , figure 2 , image 3 As shown, the method for pouring and vibrating a large-volume concrete structure during construction of the present invention is characterized in that, before the mass concrete structure 1 is poured, in addition to arranging structural steel bars 2 according to design requirements, several vibrating steel bars 3 are also arranged The vibrating steel bar 3 is made of high-rigidity carbon steel, and the top is processed with a threaded head; the vibrating steel bar 3 is required to be evenly arranged between the gaps of the structural steel bar 2 and arranged at an interval of 0.5-1.5 meters to ensure that it cannot be in contact with the structural steel bar 2; When arranging the vibrating steel bar 3, put the prefabricated cement plinth 5 with jacks on the bottom of the concrete structure 1, and require the cement pier 5 to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com