Wind turbine blade and icing preventing and removing method

A technology of wind turbine blades and blades, which is applied to wind turbines, wind turbines that are consistent with the wind direction, engines, etc. It can solve the problems of reducing the service life of the wind turbine, increasing the load, and difficult maintenance, and achieves the effect of avoiding aging and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

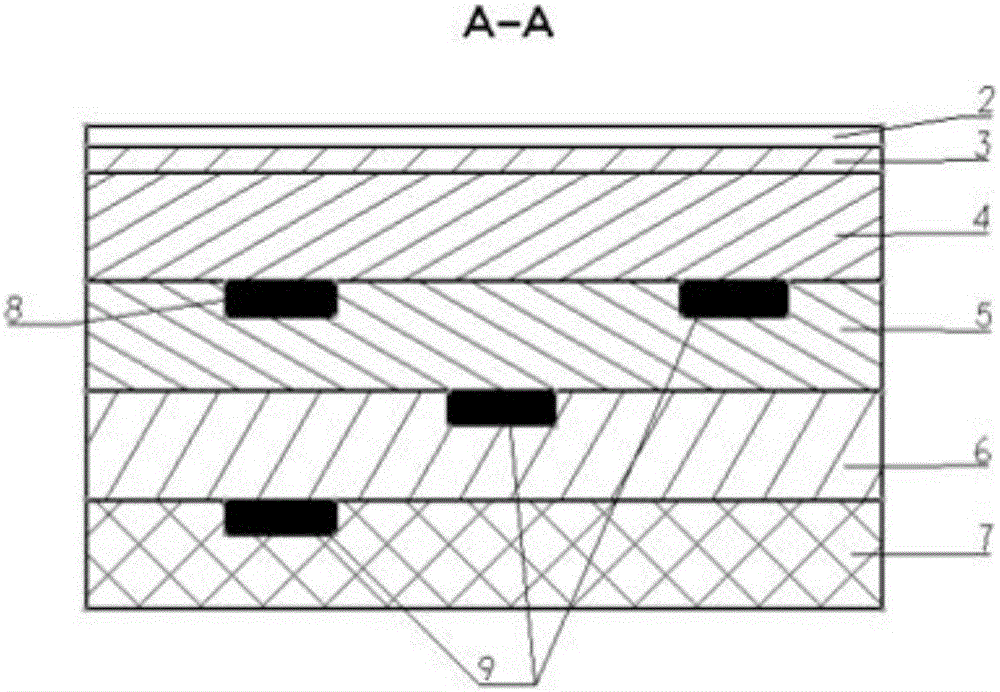

[0050] The present embodiment heating resistance wire 1 uses the resistance wire that model is KanthalA-1, and its density is 7.10g / cm 3 , the resistivity is 1.45μΩ.m, the hardness is 230Hv, and the elongation at break is 18%. The temperature sensor 9 uses a PT100 platinum resistance element and is made into a patch pattern. ±0.15°C, with high accuracy, the measurement range is -200~+200°C, and the average temperature of the area covered by the patch can be measured. The weight sensor 8 is a miniature load cell EVT-14D-500G, with a range of 0-500g, a temperature range of -10°C to 60°C, a diameter of 12mm, a height of 4mm, an input impedance of 350Ω±10Ω, and a maximum excitation of 10V DC / AC .

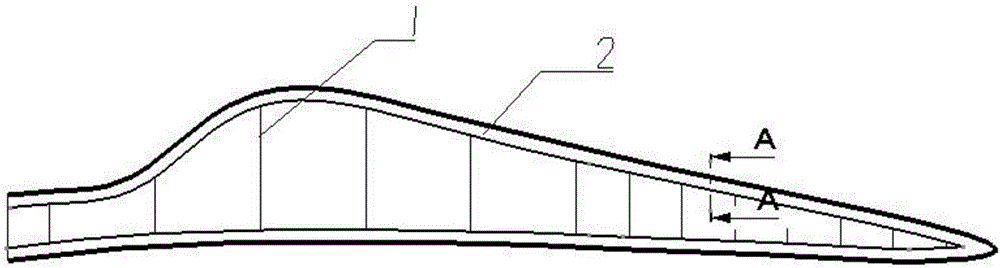

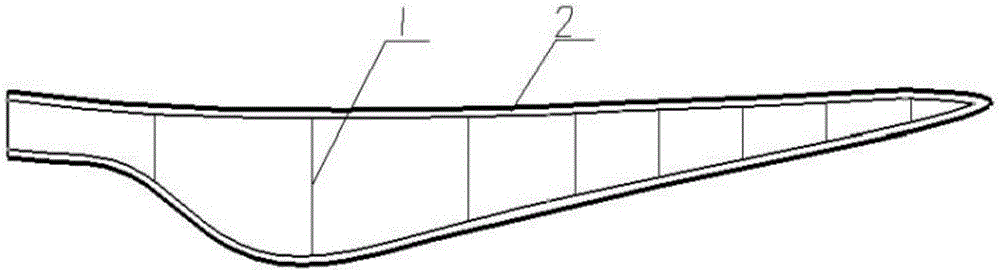

[0051] The blades of this embodiment are wind turbine blades that are mixed with carbon fiber and glass fiber. Only the key parts of the blade, such as: beams, front and rear edges, are made of carbon fiber materials. The overall blade is lighter and more rigid. The blade shell provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com