A non-contact measurement method for measuring the diameter of deep and small holes by combining images

A non-contact measurement, deep hole technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of measurement, controllable light source cannot be accurately penetrated, etc., and achieve the effects of low cost, intuitive measurement and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

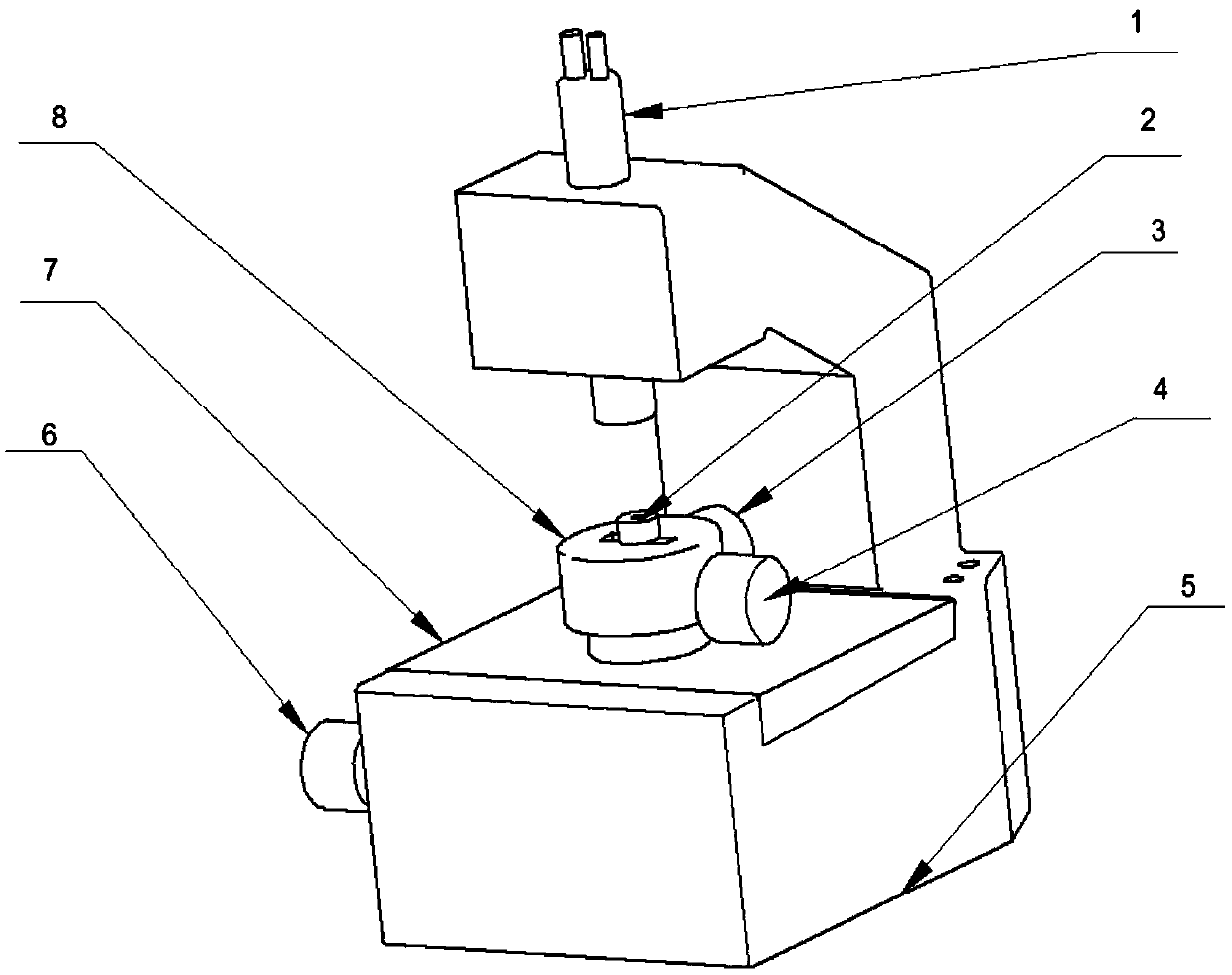

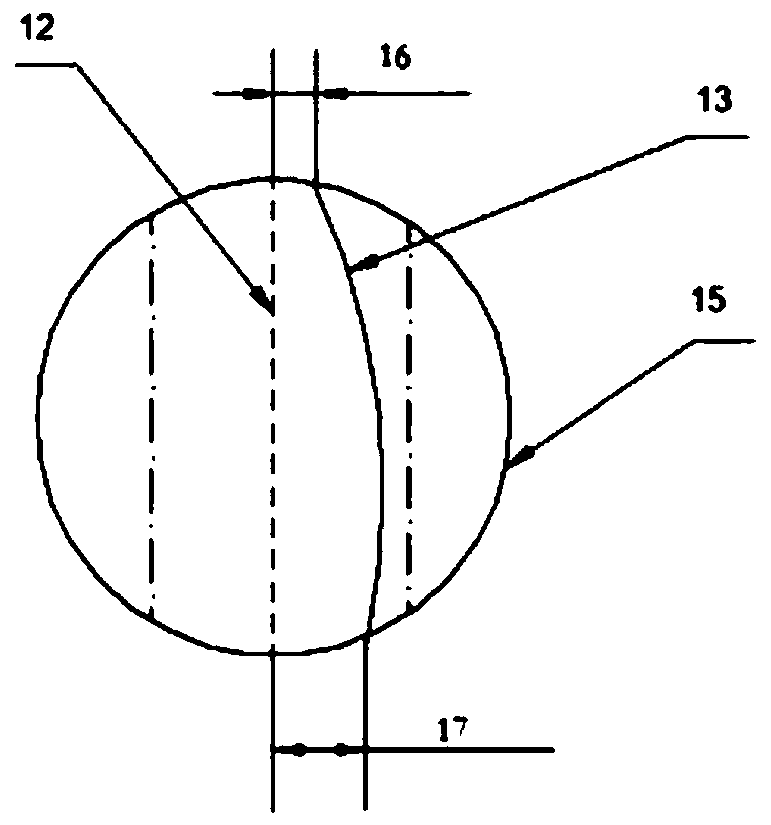

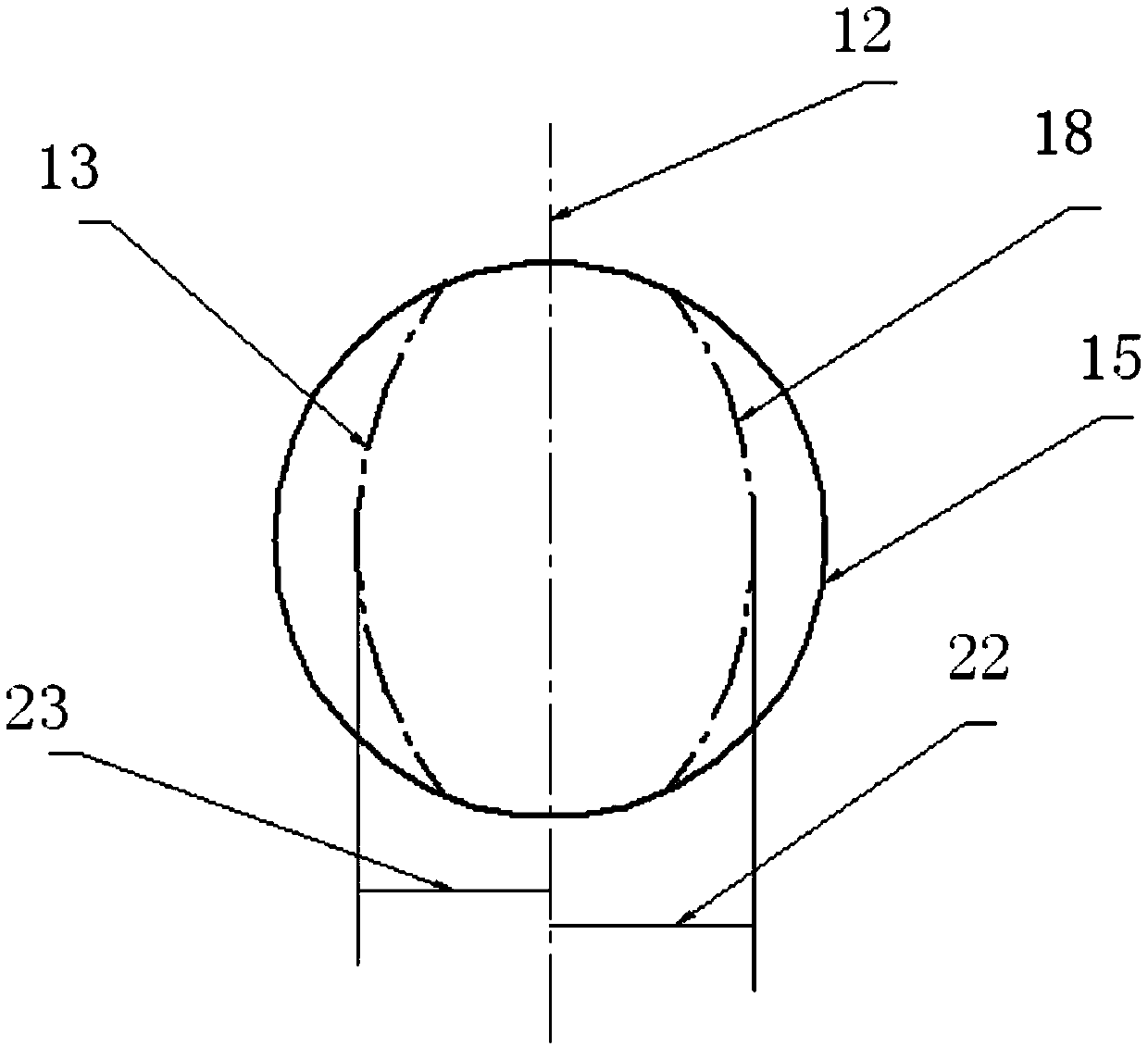

[0015] refer to Figure 1-Figure 4. In an example described below, a non-contact measurement device for measuring the diameter of deep and small holes with combined images includes: a fine-tuning table 8 for placing workpieces and a base 5 for fixing the fine-tuning table 8, and a CCD remotely controlled by a computer. The central lens 1, the CCD telecentric lens 1 faces the workpiece 2 through the arched arm of the base 5. According to the Cartesian coordinate system, the axes of the fine-tuning table 8, the Y-axis moving servo motor 3 whose two axes are perpendicular to each other, and the horizontal adjustment servo motor 4 intersect at the origin of the coordinates in the horizontal direction, and the Z axis of the origin of the coordinates coincides with the CCD telecenter The optical axis of the lens 1 and the horizontal adjustment servo motor 4 are controlled by a computer. On the upper end plane of the base 5 is provided with a mobile workbench 7 which slides along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com