Code scanning and weighing device and weighing method thereof

A weighing device and scanning code technology, applied in measuring devices, automatic feeding/discharging weighing equipment, weighing and other directions, can solve problems such as inability to record the real value of barcode information, low production efficiency, and damage to electronic scales. , to achieve the effect of facilitating traceability, reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings and embodiments.

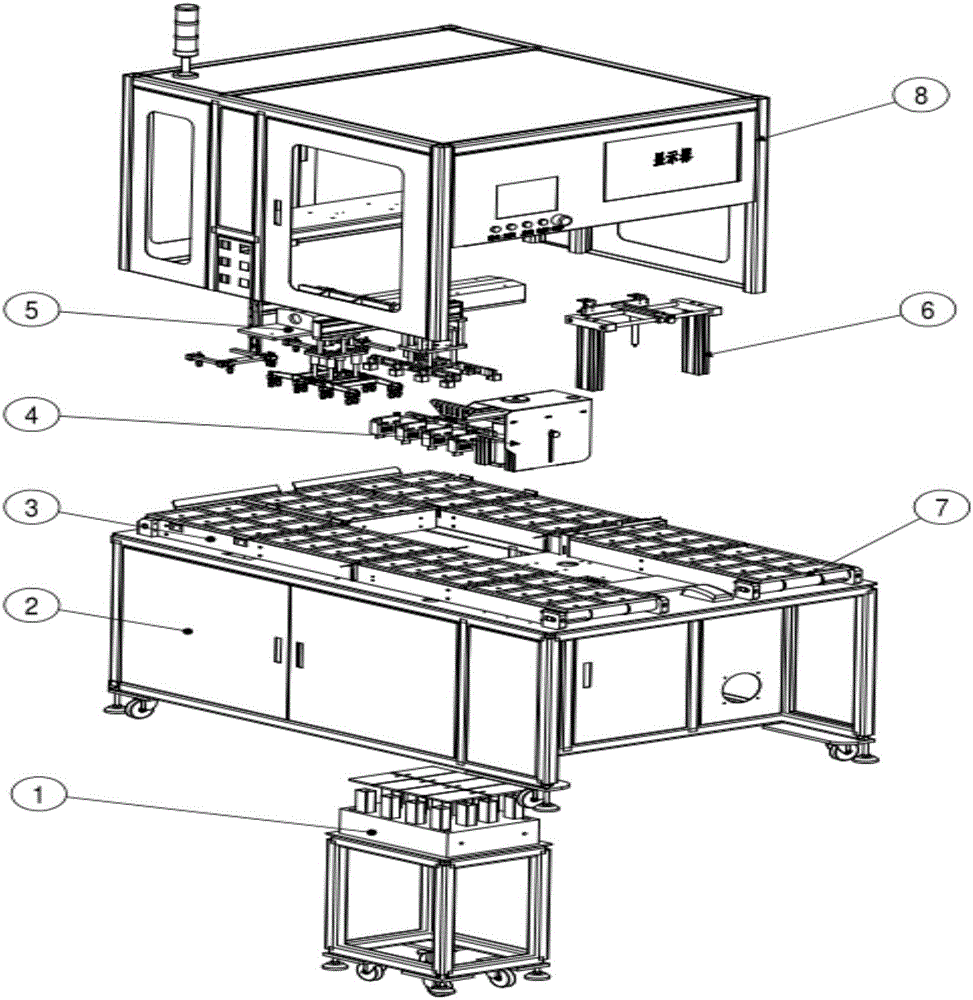

[0027] like figure 1 As shown, the code scanning weighing device of the present invention is used for weighing polymer lithium ion batteries, and it includes: a weighing platform 1, an upper frame 8, a feeding assembly 3 provided with a feeding conveyor belt, and a code scanning assembly 4 , unloading assembly 5, defective marking assembly 6, unloading assembly 7 provided with unloading conveyor belt, and lower frame 2, wherein loading assembly 3, code scanning assembly 4, defective marking assembly 6, and unloading assembly 7 are all Installed on the lower frame 2, the pick-and-discharge assembly 5 is installed on the bottom of the upper frame 8, and the upper frame 8 is sleeved on the lower frame 2.

[0028] Wherein, there is a hollowed-out area in the middle of the lower frame 2. In order to ensure that the weighing data is not affected by the vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com