Testbed for reliability of power unit of industrial robot

A technology of industrial robots and power units, which is applied in machine gear/transmission mechanism testing, machine/structural component testing, mechanical component testing, etc. It can solve problems such as high structural energy consumption, low degree of automation, and poor adjustability. Achieve high test efficiency, high degree of automation, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

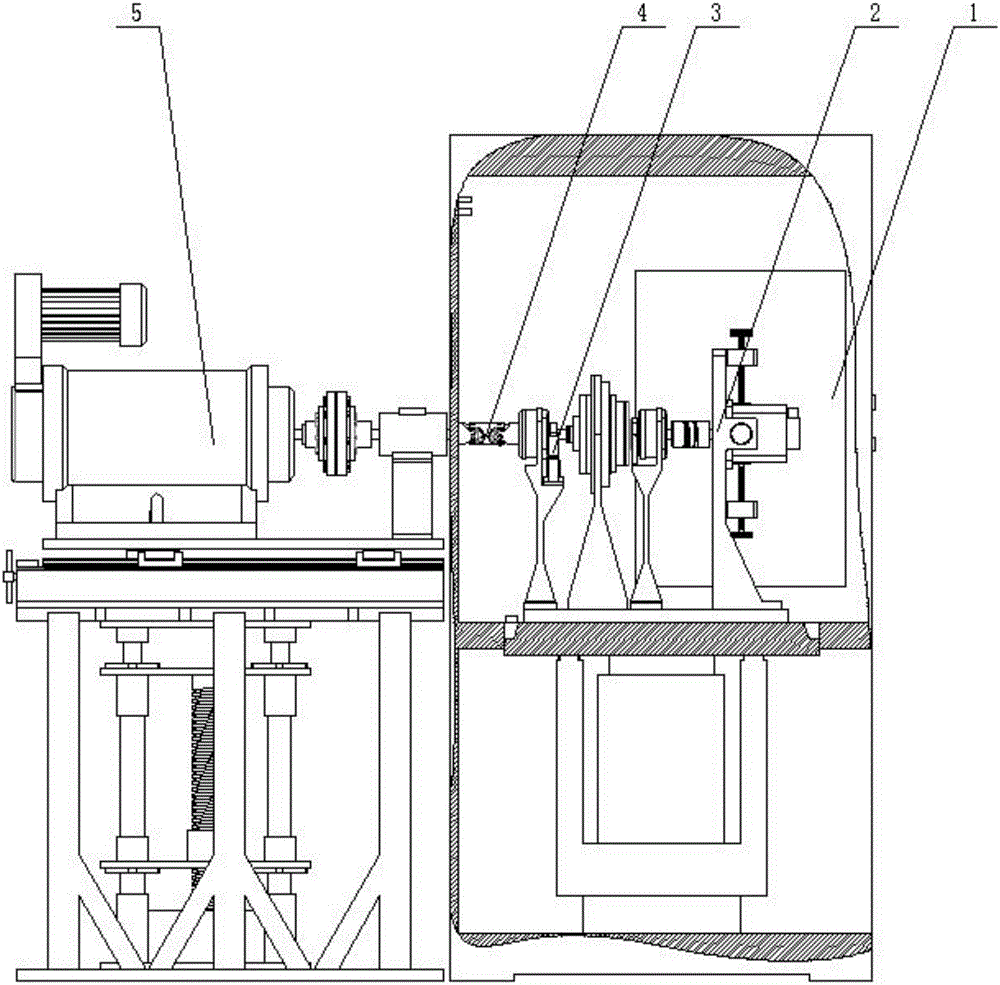

[0034] It consists of three comprehensive test chambers 1, power unit 2, radial force loading unit 3, universal joint coupling 4, and torque loading unit 5, of which power unit 2 and radial force loading unit 3 are placed in three comprehensive test chamber 1 Internally, the torque loading unit 5 is connected to the power unit 2 via a cardan coupling 4 .

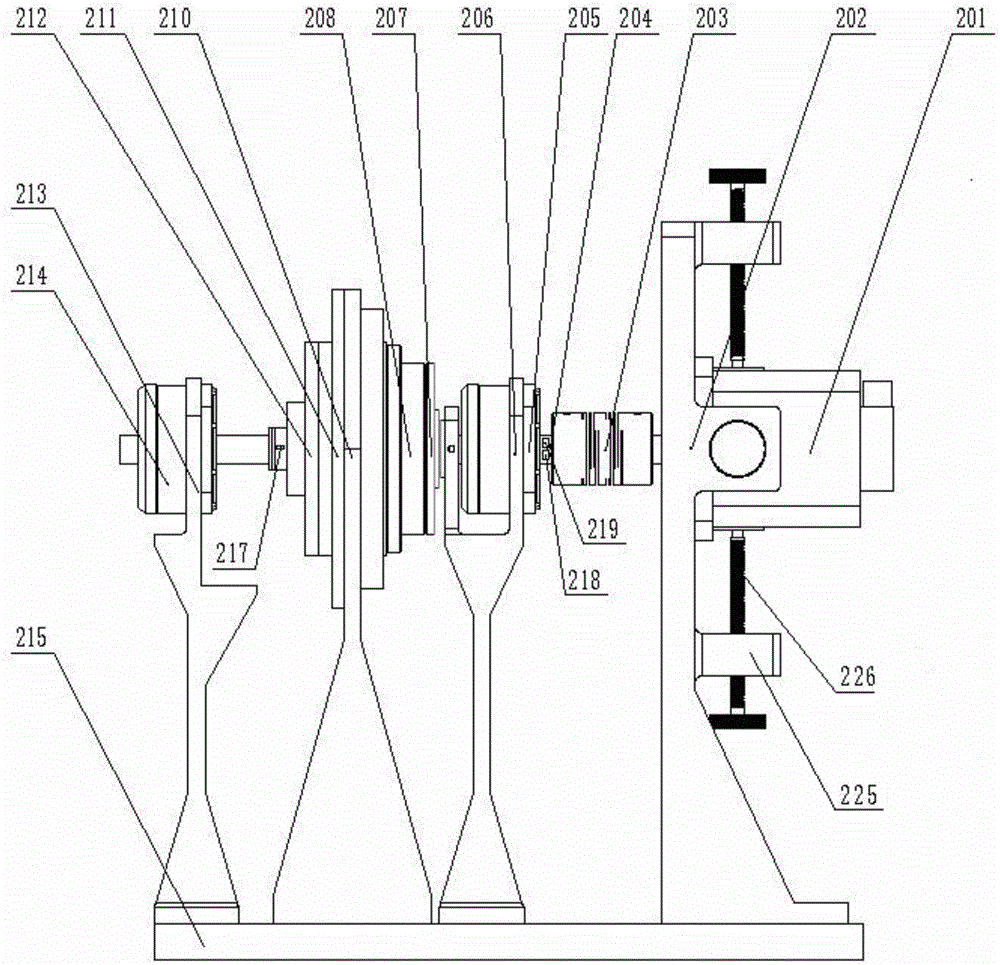

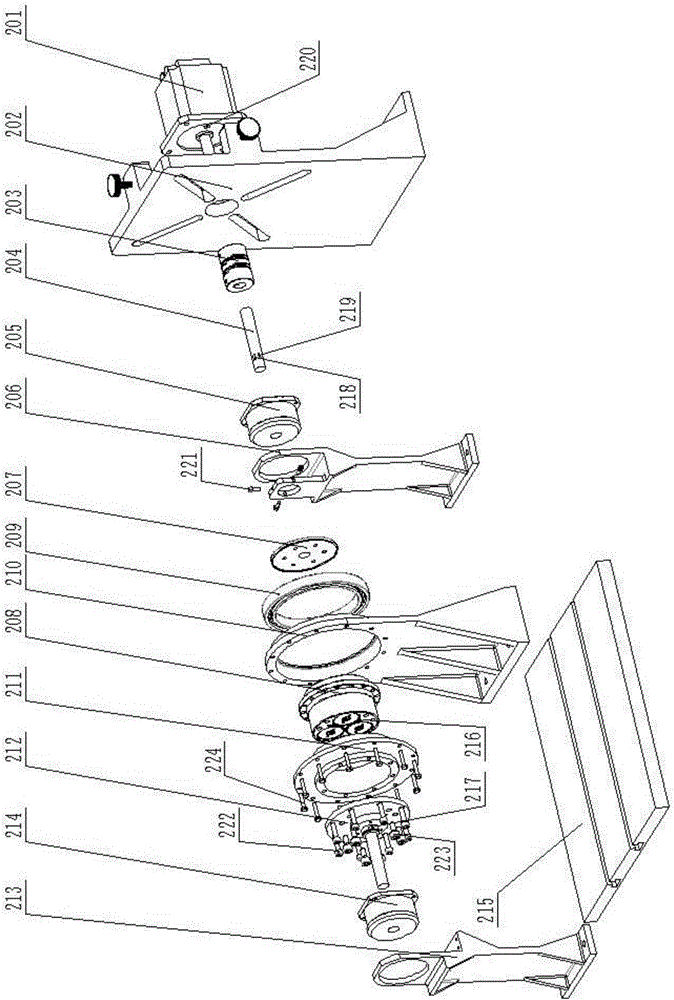

[0035]The structure of the power unit of the present invention is: motor support 202, encoder support frame one 206, reducer support 210, encoder support two 213 are all fixed on the base plate 215 by bolt connection, servo motor 201 and motor support 202 Fixedly connected, the shaft of the servo motor 201 is connected to one end of the input shaft 204 through a coupling 203, and a strain gauge 218 and an acceleration sensor 219 are installed on the input shaft 204 to measure the torque of the input shaft 204 and detect its vibration state, and rotate the encoder Device one 205 is fixedly connected with encoder support frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com